Cheesecake, a beloved dessert enjoyed worldwide, is not immune to food safety hazards that can compromise its quality and pose health risks to consumers. Three primary food safety hazards associated with cheesecake include biological contaminants, such as bacteria like *Salmonella* and *E. coli*, which can thrive in dairy-based ingredients if not properly handled or stored; chemical hazards, such as cross-contamination from allergens or cleaning agents, which can occur during preparation or packaging; and physical hazards, like foreign objects (e.g., metal fragments or plastic) that may inadvertently enter the product during manufacturing. Understanding and mitigating these risks is essential to ensure the safety and integrity of this popular treat.

| Characteristics | Values |

|---|---|

| Biological Hazards | 1. Pathogenic Bacteria: Salmonella, Listeria monocytogenes, E. coli can grow in cheesecake if not stored properly (below 40°F/4°C) or if ingredients are contaminated. 2. Mold: Can develop on cheesecake if left at room temperature for too long or if ingredients are past their prime. |

| Chemical Hazards | 1. Allergens: Common allergens like eggs, milk, wheat, and nuts are present in cheesecake. Cross-contamination during preparation can be a serious risk for allergic individuals. |

| Physical Hazards | 1. Foreign Objects: Fragments of utensils, packaging, or other materials can accidentally end up in the cheesecake during preparation. |

Explore related products

What You'll Learn

- Biological Hazards: Bacteria, molds, and pathogens like Salmonella and E. coli can contaminate cheesecake ingredients

- Chemical Hazards: Cleaning agents, pesticides, or allergens (e.g., nuts) may accidentally enter the cheesecake

- Physical Hazards: Foreign objects like metal, plastic, or glass fragments can pose risks during production

- Temperature Control: Improper refrigeration or storage can lead to spoilage and bacterial growth in cheesecake

- Cross-Contamination: Shared utensils or surfaces can transfer allergens or pathogens between ingredients or products

Biological Hazards: Bacteria, molds, and pathogens like Salmonella and E. coli can contaminate cheesecake ingredients

Cheesecake, a beloved dessert, is particularly vulnerable to biological hazards due to its ingredients—cream cheese, eggs, and dairy—which provide an ideal environment for bacterial growth. These ingredients, when not handled or stored properly, can become breeding grounds for harmful microorganisms like Salmonella, E. coli, and Listeria. For instance, raw or undercooked eggs in the batter can introduce Salmonella, while contaminated dairy products may harbor Listeria, a pathogen especially dangerous for pregnant women, the elderly, and immunocompromised individuals. Understanding these risks is the first step in preventing foodborne illnesses.

To mitigate biological hazards, strict adherence to food safety practices is essential. Start by ensuring all ingredients are sourced from reputable suppliers and stored at the correct temperatures. Eggs should be refrigerated at or below 40°F (4°C), and dairy products must be kept cold throughout transportation and storage. When preparing cheesecake, use pasteurized eggs or egg products to eliminate the risk of Salmonella. Additionally, maintain a clean workspace and sanitize utensils to prevent cross-contamination. For example, never use the same knife to cut raw ingredients and then mix the batter without washing it thoroughly.

Temperature control is another critical factor in preventing bacterial growth. After baking, cheesecake should be cooled rapidly to below 40°F (4°C) within two hours to inhibit the proliferation of pathogens. If the cheesecake is not consumed immediately, refrigerate it promptly. Avoid leaving it at room temperature for extended periods, as this creates a "danger zone" (40°F to 140°F or 4°C to 60°C) where bacteria multiply rapidly. For instance, E. coli can double in number every 20 minutes under these conditions, significantly increasing the risk of contamination.

Finally, educate yourself and your team on the symptoms of foodborne illnesses caused by these pathogens. Salmonella infection, for example, typically presents as diarrhea, fever, and abdominal cramps within 6 to 72 hours of consumption. E. coli can cause severe stomach cramps, diarrhea, and vomiting, often within 3 to 4 days. Recognizing these symptoms early can help in seeking timely medical attention and preventing further spread. By combining vigilance, proper handling, and knowledge, you can ensure that your cheesecake remains a safe and delightful treat for all.

Steak Egg and Cheese Return: Anticipated Comeback Date Revealed

You may want to see also

Chemical Hazards: Cleaning agents, pesticides, or allergens (e.g., nuts) may accidentally enter the cheesecake

Chemical hazards in cheesecake production pose a significant risk when cleaning agents, pesticides, or allergens inadvertently contaminate the product. For instance, residual cleaning chemicals like quaternary ammonium compounds (QUATS) can persist on surfaces if not rinsed thoroughly, potentially transferring to the cheesecake during preparation. Even trace amounts—as little as 10 ppm—can cause gastrointestinal irritation in consumers. Similarly, pesticide residues from unwashed berries or contaminated dairy ingredients may exceed safe limits (e.g., 0.01 mg/kg for organophosphates), leading to acute toxicity. Allergens, such as trace nuts from shared equipment, require detection at levels as low as 5 ppm to prevent severe reactions in sensitive individuals.

Preventing chemical contamination begins with rigorous sanitation protocols. Use food-safe cleaning agents and ensure surfaces are rinsed with potable water to eliminate residues. Implement color-coded equipment to avoid cross-contamination, especially for allergen-containing ingredients. For raw materials, source dairy, fruits, and nuts from suppliers with verified pesticide and allergen control programs. Regularly audit suppliers to confirm compliance with safety standards, such as the FDA’s maximum residue limits for pesticides. In-house, conduct swab tests for allergens and chemical residues on surfaces and equipment before production starts.

When handling allergens, designate separate preparation areas and use dedicated tools to minimize cross-contact. Clearly label ingredients and finished products to avoid mix-ups. For example, if a facility processes both nut-free and nut-containing cheesecakes, store nuts in sealed containers and clean shared equipment with allergen-removing solutions. Train staff to recognize allergen symbols and follow protocols strictly, as even a single oversight can lead to recalls or lawsuits.

In the event of suspected contamination, act swiftly. Quarantine affected batches and trace the source using batch records and supplier data. Notify regulatory authorities if the issue poses a public health risk. For instance, if a cleaning agent is found in a cheesecake batch, recall the product and conduct a root-cause analysis to prevent recurrence. Educate consumers about potential risks through clear labeling and allergen declarations, ensuring transparency and trust.

Ultimately, vigilance and systematic controls are key to mitigating chemical hazards in cheesecake production. By integrating preventive measures, regular testing, and responsive protocols, manufacturers can safeguard both product quality and consumer health. Prioritize training and documentation to create a culture of accountability, ensuring every step from ingredient sourcing to packaging minimizes the risk of chemical contamination.

Launching Your Dream: A Guide to Opening a Wine & Cheese Shop

You may want to see also

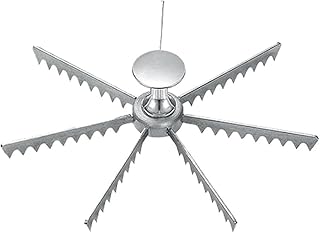

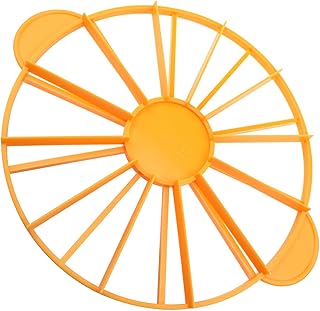

Physical Hazards: Foreign objects like metal, plastic, or glass fragments can pose risks during production

Foreign objects in food products, particularly delicate items like cheesecake, can turn a delightful dessert into a dangerous experience. Metal, plastic, or glass fragments, even in minute quantities, pose significant physical hazards. These contaminants often originate from equipment wear, packaging materials, or human error during production. For instance, a broken machine part or a misplaced utensil can introduce metal shards, while plastic wrap or storage containers may degrade under certain conditions, leaving behind microscopic particles. The risk escalates in automated production lines, where high-speed processes increase the likelihood of undetected foreign matter.

Detecting these hazards requires rigorous quality control measures. Metal detectors and X-ray machines are commonly employed to identify metallic and dense non-metallic objects, respectively. However, smaller particles, especially those made of plastic or glass, may evade detection, necessitating additional safeguards. Regular equipment maintenance and employee training are critical to minimizing contamination. For example, routine inspections of mixing blades, conveyor belts, and cutting tools can prevent metal fatigue and breakage. Similarly, using food-grade materials for packaging and storage reduces the risk of plastic or glass fragments entering the product.

The consequences of foreign object contamination extend beyond immediate consumer injury. Legal repercussions, brand damage, and product recalls can cripple a business. A single incident can lead to costly lawsuits and regulatory penalties, not to mention the loss of consumer trust. For instance, a 2019 case involving glass fragments in a popular cheesecake brand resulted in a nationwide recall, costing the company millions in lost sales and reputational harm. Such incidents underscore the importance of proactive measures to safeguard both consumers and businesses.

Practical steps to mitigate physical hazards include implementing Hazard Analysis and Critical Control Points (HACCP) systems tailored to cheesecake production. This involves identifying potential contamination points, such as ingredient handling and packaging, and establishing monitoring procedures. For example, sieving dry ingredients like flour or sugar can remove foreign matter before mixing. Additionally, using clear, high-quality packaging materials allows for visual inspection before sealing. Employees should also wear appropriate attire, including hairnets and gloves, to prevent physical contaminants from entering the production area.

In conclusion, while physical hazards like metal, plastic, or glass fragments are preventable, their impact on food safety and business integrity cannot be overstated. By adopting a combination of technological solutions, stringent protocols, and employee vigilance, producers can significantly reduce the risk of contamination. Ultimately, ensuring the safety of cheesecake and other food products requires a commitment to excellence at every stage of production, from sourcing ingredients to delivering the final product.

Why Raw Cheese Imports Are Banned: Uncovering the Legal Reasons

You may want to see also

Explore related products

$12.99 $28.09

Temperature Control: Improper refrigeration or storage can lead to spoilage and bacterial growth in cheesecake

Cheesecake, a delicate dessert with a creamy texture, is particularly susceptible to temperature-related hazards. The ideal storage temperature for cheesecake is between 35°F and 38°F (1.7°C to 3.3°C). At temperatures above 40°F (4.4°C), bacteria such as *Salmonella*, *E. coli*, and *Listeria* can multiply rapidly, doubling every 20 minutes. This exponential growth can transform a perfectly safe dessert into a potential health risk within hours. For instance, a cheesecake left at room temperature (68°F to 72°F or 20°C to 22°C) for more than 2 hours enters the "danger zone," where bacterial activity peaks.

Consider the logistics of serving cheesecake at events. If the dessert is displayed on a buffet table without proper cooling, its internal temperature can rise quickly. To mitigate this, use chilled serving plates or place ice packs beneath the display. For home storage, always refrigerate cheesecake in airtight containers to prevent moisture loss and cross-contamination. If freezing, wrap the cheesecake tightly in plastic wrap and aluminum foil to maintain quality for up to 2 months. Thawing should occur slowly in the refrigerator, not at room temperature, to avoid uneven texture and bacterial growth.

The science behind temperature control lies in slowing enzymatic reactions and microbial activity. Cheesecake’s high moisture content and protein-rich ingredients (cream cheese, eggs) create an ideal environment for bacteria. Refrigeration reduces the metabolic rate of these microorganisms, extending shelf life. However, improper refrigeration—such as overcrowding the fridge or placing cheesecake near the door—can lead to temperature fluctuations. Invest in a refrigerator thermometer to monitor consistency, ensuring the appliance maintains the recommended 35°F to 38°F range.

A comparative analysis of cheesecake storage methods reveals the importance of temperature control. Cheesecake stored at 45°F (7.2°C) shows visible spoilage (mold, off-odors) within 3 days, while one stored at 38°F lasts up to 7 days. Commercially produced cheesecakes often include preservatives like sorbic acid or potassium sorbate, but these additives are less common in homemade versions, making temperature control even more critical. For bakeries and restaurants, implementing a first-in, first-out (FIFO) system ensures older products are used promptly, reducing the risk of prolonged storage.

In conclusion, mastering temperature control is non-negotiable for cheesecake safety. From production to consumption, maintaining the correct temperature range prevents spoilage and bacterial contamination. Practical steps include using chilled serving tools, monitoring refrigerator temperatures, and adhering to storage guidelines. By prioritizing these measures, both home bakers and professionals can safeguard the integrity of this beloved dessert, ensuring every slice is as safe as it is indulgent.

Aldi Advent Calendar Cheese Variety: Are All 24 Cheeses Unique?

You may want to see also

Cross-Contamination: Shared utensils or surfaces can transfer allergens or pathogens between ingredients or products

Cross-contamination in cheesecake preparation is a silent threat that can turn a delightful dessert into a health hazard. Imagine using the same knife to cut a nut-based crust and then slicing a fresh strawberry topping. Unseen traces of nuts can linger on the blade, potentially triggering severe allergic reactions in sensitive individuals. This scenario underscores the critical need for vigilance in kitchen practices.

To prevent cross-contamination, adopt a "one tool, one task" rule. Designate specific utensils and cutting boards for allergenic ingredients like nuts, gluten, or dairy. For instance, use a red-handled knife exclusively for nut-based components and a blue one for fruit toppings. Color-coding simplifies identification and reduces the risk of accidental mixing. Additionally, clean surfaces with hot, soapy water between tasks, or use disposable barriers like parchment paper for added protection.

Pathogens, such as *Salmonella* or *E. coli*, pose another risk, especially when raw eggs or unpasteurized cream cheese are involved. A single contaminated utensil can spread these bacteria to otherwise safe ingredients. For example, if a spatula used to mix raw eggs comes into contact with the final cheesecake batter, it can introduce harmful microbes. Always sanitize utensils with a solution of one tablespoon of bleach per gallon of water, and allow them to air-dry before reuse.

Education is key to combating cross-contamination. Train kitchen staff or family members to recognize high-risk scenarios, such as using the same whisk for raw and cooked ingredients. Implement a checklist to ensure all surfaces and tools are cleaned and sanitized between tasks. For home bakers, invest in affordable, allergen-specific utensils to minimize risks. Remember, the goal isn’t just to create a delicious cheesecake but to ensure it’s safe for everyone to enjoy.

Finally, consider the environment. Busy kitchens often lead to shortcuts, increasing the likelihood of cross-contamination. Organize your workspace to keep allergenic and non-allergenic ingredients physically separated. Store nuts, for instance, in sealed containers on a different shelf from fruits or dairy. By combining awareness, organization, and strict hygiene practices, you can safeguard your cheesecake from becoming a vehicle for allergens or pathogens.

Bacon Egg and Cheese: The Perfect Cheese Pairing Revealed

You may want to see also

Frequently asked questions

A biological hazard in cheesecake production includes bacteria like *Salmonella* or *E. coli*, which can contaminate ingredients such as raw eggs, cream cheese, or unwashed fruits, leading to foodborne illnesses if not properly handled or stored.

A chemical hazard in cheesecake could be the presence of cleaning agents or sanitizers in ingredients or equipment if not properly rinsed, or the use of expired baking powder or artificial additives that may cause adverse health effects.

A physical hazard in cheesecake includes foreign objects like metal fragments from utensils, plastic from packaging, or even fruit pits/seeds that accidentally end up in the batter, posing a choking or injury risk to consumers.