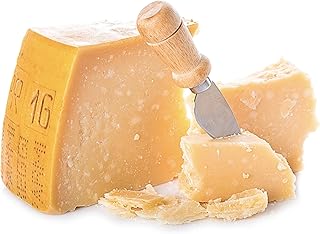

Parmesan cheese is a hard, granular Italian cheese with a fruity and nutty flavour. It is made from cow's milk and aged for at least 12 months, though some varieties are aged for up to four years. The milk used to make Parmesan is typically a mixture of skimmed or partially skimmed milk and whole milk. This mixture is heated and stirred rapidly in a vat, drying out the curds and creating the cheese's signature granular texture.

| Characteristics | Values |

|---|---|

| Milk Type | Cow's milk |

| Milk Temperature | 55-60F |

| Milk Fat Content | 2.5% |

| Milk Source | Cows grazing on fresh grass and hay |

| Milk Treatment | Pasteurised or unpasteurised |

| Milk Mixing | Mixed with whole milk from morning milking and naturally skimmed milk from previous evening's milking |

Explore related products

What You'll Learn

Parmesan is made from cow's milk

Parmesan cheese, or Parmigiano Reggiano, is made from cow's milk. It is a hard, granular cheese that is typically grated and used in dishes such as pasta, soups, and risottos. It can also be enjoyed on its own as a snack. Parmesan is characterised by its hard, gritty texture and fruity and nutty flavour.

The process of making Parmesan cheese involves combining skimmed or partially skimmed milk from the previous evening's milking with fresh whole milk from the morning's milking. This results in a part-skim mixture with a fat percentage of approximately 2.5%. The milk is then heated slowly to a temperature between 91-93°F (32.8-33.9°C). The small curd size, rapid stirring, and high heat help to dry the curds evenly, and the curds quickly cook down to a smaller rice or barley grain size.

The production of Parmesan cheese is governed by specific regulations, particularly within the European Union. Under Italian law, only cheese produced in specific provinces, such as Parma, Reggio Emilia, and Modena, can be labelled as "Parmigiano-Reggiano". European law also classifies the name "Parmesan" as a protected designation of origin. These regulations ensure the integrity and quality of traditional Italian food products.

Outside of the European Union, the term "Parmesan" may refer to locally produced imitations or cheeses inspired by the original Italian Parmesan. These cheeses are still made from cow's milk but may have different ageing requirements and production processes. For example, in the United States, a cheese labelled as "Parmesan" may be an imitation or a high-quality cheese inspired by Parmigiano-Reggiano.

In summary, Parmesan cheese, or Parmigiano Reggiano, is a renowned Italian cheese made from cow's milk. It is produced through a specific process that involves combining and heating milk to create the characteristic texture and flavour. The production and naming of Parmesan cheese are regulated within the European Union, while outside of this region, the term "Parmesan" may refer to a variety of similar cheeses.

Feta Cheese: An Indian Cooking Twist

You may want to see also

The milk is usually raw

Parmesan cheese, or Parmigiano Reggiano, is a hard, granular Italian cheese produced from cow's milk. It is typically aged for at least 12 months, with some varieties aged for up to four years. The milk used in the production of Parmesan is usually raw and unpasteurised.

The process of making Parmesan cheese begins with the collection of fresh raw milk after the evening milking and again in the morning. The evening milk is left to set at room temperature, and the cream is skimmed off the next morning. This low-fat milk is then mixed with the full-fat milk collected in the morning, resulting in a part-skim mixture. The milk is then slowly heated to a specific temperature range, and the curds are formed and stirred rapidly in a vat. The curds are then consolidated into a curd mass, and the cheese begins to take shape.

Using raw milk is essential to the traditional Parmesan cheese-making process. The raw milk is not pasteurised, preserving the natural enzymes and bacteria present in the milk. These enzymes and bacteria play a crucial role in the development of Parmesan's distinct flavour and texture. The high free amino acid content and the level of free glutamate contribute to the cheese's salty, umami character.

The use of raw milk also imparts a unique flavour profile to the cheese. The cows' diet of fresh grass and hay, as stipulated by the PDO designation, is reflected in the milk's composition. This, in turn, influences the final product, giving Parmesan its characteristic fruity and nutty notes. The raw milk also contributes to the cheese's granular texture, which is highly valued by cheese connoisseurs.

While raw milk is traditional, some modern variations of Parmesan cheese may use pasteurised milk. This practice is more common in regions outside of Italy, where regulations and standards may differ. However, within the European Union, Parmesan and Parmigiano-Reggiano are legally required to adhere to strict production methods, including the use of raw, unpasteurised milk.

Creative Ways to Use Leftover Raclette Cheese

You may want to see also

It can be skimmed or partially skimmed

Parmesan cheese, or Parmigiano Reggiano, is a hard, granular cheese produced from cow's milk. It is characterised by its hard, gritty texture and fruity and nutty flavour. The cheese is typically consumed grated over pasta, soups, and risottos, or even on its own as a snack.

Parmesan cheese is made from skimmed or partially skimmed milk. The milk is left to set at room temperature, allowing natural creaming to occur. The following morning, the milk is skimmed to remove the cream, resulting in low-fat milk. This process of skimming the milk helps to reduce the fat content and achieve the desired casein-to-fat ratio in the final product.

The skimmed milk is then combined with fresh whole milk, creating a part-skim mixture. This mixture of skimmed and whole milk is essential to maintain the proper ratio of casein, a protein found in milk, to fat. By adjusting the fat content of the milk, cheese makers can ensure the final product has the desired texture and consistency.

The process of skimming the milk also allows for some acidity to develop naturally. This acidity plays a role in the cheese-making process, as it can influence the flavour and texture of the final product.

Additionally, the skimmed milk used in Parmesan cheese production may undergo a clarification process to further adjust its fat content. This step helps ensure that the milk meets the specific requirements for making traditional Parmigiano-Reggiano.

Overall, the use of skimmed or partially skimmed milk is an important aspect of Parmesan cheese production, as it contributes to the unique characteristics of this popular cheese.

Creative Culinary Uses for Blue Stilton Cheese

You may want to see also

Explore related products

The milk is heated to 91-93°F

Parmesan cheese is traditionally made from cow's milk. The milk used is typically a mixture of skimmed and full-fat milk, with the final fat percentage for the combined milk being approximately 2.5%. The milk is heated to 91-93°F in a process that goes against the basics of cheese-making, which typically involves raising the temperature only a couple of degrees per minute over a long time to prevent surface hardening. However, the higher heat, combined with rapid stirring in the vat, effectively dries the curds out evenly. This results in curds that quickly cook down to a smaller rice or barley grain size and easily consolidate into a nice curd mass.

To achieve this temperature, a milk pot in a water bath is the best method, but it can also be done directly on the stovetop with careful heating. The water bath method involves monitoring both the bath and milk temperatures with thermometers and maintaining a 10-20°F differential between the two until the target milk temperature is approached. This heating method is essential to achieving the desired curd size and consistency.

Once the milk reaches the target temperature of 91-93°F, the water jacket needs to be cooled to 135°F, and stirring should be continued. Depending on the milk used, the curd should be ready to consolidate within 5-10 minutes. At this stage, the cheese maker assesses the state of the formed curds. The final curd should be dry but still able to hold together when pressed.

The heating and stirring process is a critical step in the Parmesan cheese-making process, as it directly impacts the size and consistency of the curds, which, in turn, affects the overall quality and texture of the final cheese product.

Mastering the Art of Using a Pronged Cheese Knife

You may want to see also

It's then left to stand overnight

Parmesan cheese is traditionally made from cow's milk. The whole milk of the morning milking is mixed with the naturally skimmed milk of the previous evening's milking, creating a part-skim mixture. This mixture is then left to stand overnight, allowing the milk to curdle.

The process of making Parmesan cheese is a lengthy one, and this step of letting the milk stand overnight is crucial to the development of the cheese's flavour and texture. During this time, the milk mixture sits undisturbed, allowing the natural bacteria within it to begin breaking down the milk sugars. This process kickstarts the transformation of sweet milk into a more sour and tangy product, which will eventually become the signature sharp-tasting Parmesan cheese.

Leaving the milk to stand also helps to develop the cheese's texture. As the milk sits, its proteins begin to denature and form a gel-like structure. This structure is the foundation of the cheese curd, which will eventually give Parmesan its characteristic granular texture.

This step of leaving the milk to stand overnight showcases the art and science of cheesemaking. It highlights the cheesemaker's understanding of the complex interplay between time, temperature, and bacteria, which is fundamental to the craft.

After the milk has stood overnight, the next steps in the cheesemaking process begin. The milk mixture is then heated, and additional ingredients like whey and rennet are added to form the curd. The curds are then separated from the whey and undergo further processing to become the iconic Parmesan cheese.

The Art of Cheese-Making: A Beginner's Guide

You may want to see also

Frequently asked questions

Parmesan cheese is traditionally made from cow's milk. The milk is collected after the evening milking and then again the following morning. The evening milk is left to set at room temperature and then skimmed the next morning. The skimmed milk is then mixed with the full-fat morning milk.

In the United States, Parmesan cheese is often made from a mixture of other cheeses and cellulose. Outside of the European Union, Parmesan is a family of hard-grating cheeses made from cow's milk and inspired by the original Italian cheese.

The traditional Italian Parmesan cheese is called Parmigiano Reggiano. It is made from unpasteurised cow's milk.