Cheese is a dairy product made from milk. It is produced in a variety of flavours, textures, and forms through the coagulation of milk protein. The process of making cheese involves separating the milk into curds (solids) and whey (liquid). The curds are then drained, shaped, salted, and aged to develop flavour and texture. The type of milk used, bacterial cultures, curd processing, and aging methods all influence the variety of cheese produced.

| Characteristics | Values |

|---|---|

| Main Ingredient | Milk |

| Milk Type | Cow, Goat, Sheep, Buffalo, Camel, Horse, Yak |

| Milk Composition | 80-87% water, fat, protein, sugar, minerals |

| Milk Treatment | Pasteurization, Standardization |

| Coagulation | Rennet, Bacterial Enzymes, Acid |

| Starter Culture | Lactic Acid Bacteria |

| Secondary Culture | Yes |

| Salt | Yes |

| Aging | Yes |

| Packaging | Vacuum Packaging, Gas-Flushing |

Explore related products

What You'll Learn

Milk pasteurisation

Milk is the star ingredient in cheese. It is used to make the cheese curds that give cheese its texture and flavour. Milk is an excellent medium for microbial growth and when stored at room temperature, bacteria and other pathogens proliferate. This is why milk is pasteurised—to destroy harmful bacteria and other pathogens.

Pasteurisation is a food preservation process that involves treating milk with mild heat, usually to less than 100°C (212°F), to eliminate pathogens and extend shelf life. It is named after French microbiologist Louis Pasteur, whose research in the 1860s demonstrated that heating wine could deactivate unwanted microorganisms. Pasteurisation is widely used in the dairy industry to preserve and ensure the safety of milk and other dairy products.

The process of pasteurisation involves heating every particle of milk to a certain temperature for a set period of time. The most common method of pasteurisation in the United States is High Temperature Short Time (HTST) pasteurisation, which uses metal plates and hot water to raise milk temperatures to at least 161°F (71°C) for at least 15 seconds, followed by rapid cooling. Higher Heat Shorter Time (HHST) is a similar process that uses slightly different equipment and higher temperatures for a shorter time. Ultra Pasteurised (UP) products, meanwhile, must be heated to at least 138°C (280°F) for two seconds. This results in a longer shelf life but the product still requires refrigeration.

The original method of pasteurisation was vat pasteurisation, which involves heating milk or other liquid ingredients in a large tank for at least 30 minutes.

According to the US Food and Drug Administration (FDA), for every 2 billion servings of pasteurised milk or milk products consumed in the US, only about one person becomes ill.

Enhancing Chicken with Cheddar Cheese: A Tasty Guide

You may want to see also

Curdling milk

Milk is used to make cheese, but not all types of milk are suitable for this purpose. Cow's milk is the most commonly used milk for cheesemaking because it is widely available and has optimal amounts of fat and protein. However, other types of milk such as sheep's milk, buffalo milk, camel's milk, horse milk, and yak's milk can also be used.

The process of curdling milk is an important step in cheesemaking. Curdling is the process of breaking an emulsion or colloid into large parts of different compositions through physio-chemical processes. During curdling, the pH of the milk decreases, and it becomes more acidic. This acidity helps with curdling, preservation, and flavour development.

There are several methods to curdle milk. One way is to add bacteria or starter cultures, which contain living bacteria that eat the lactose sugar in milk and turn it into lactic acid. Another way is to add an acid such as lemon juice or vinegar directly to the milk, which will decrease its pH and cause it to curdle. A third method is to add enzymes, typically rennet, which is produced naturally in the stomachs of calves and other mammals to help them digest milk. Rennet causes the milk protein casein to form chains and develop a mesh-like network or gel, trapping water and fat. This semisolid gel is the curd.

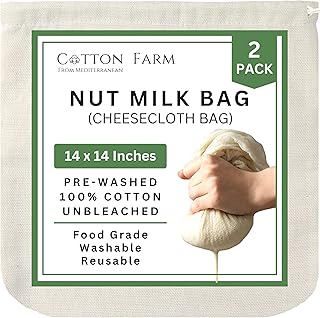

Once the milk has curdled and formed curds, the next step is to separate the curds from the whey. The whey is the liquid that remains after the milk has curdled, and it can be removed by filtering the mixture through a cloth bag or using a fine mesh sieve or cheesecloth. After the whey is removed, the curds are allowed to stick together and form a mat. Salt and spices can then be added to enhance flavour and regulate moisture content, which affects the texture of the cheese.

Charcuterie Cheese: Selecting the Perfect Pair

You may want to see also

Separating curds and whey

Milk is used to make cheese. The process of cheese-making involves separating curds and whey. Curds are the solids formed when milk proteins coagulate, while whey is the liquid that remains after this coagulation.

To make cheese at home, start by choosing the freshest milk available. Raw milk is the best option, but store-bought milk can also be used. Heat the milk in a large saucepan to around 38°C (warm but not hot), then turn off the heat. Add an acidic agent such as lemon juice, vinegar, or rennet diluted in water, and stir. Leave the saucepan for about half an hour; the milk will gradually solidify. If it doesn't, add more acid.

Once the milk has solidified, use a long knife to cut it into 1-inch squares. This separates the milk into curds (the solid bits) and whey (the liquid bits). Carefully spoon the curds into a colander or sieve placed over another pot or pan to collect the whey. Let the curds drain for about 2-3 hours. If you want a firmer cheese, place something heavy on top of the curds.

After draining, break up the curds and mix in salt to taste. Place the salted curds in a dish and microwave for short intervals, stirring in between, until the cheese is elastic. Form the cheese into a ball and drop it into cold salted water. Repeat this process with the remaining curds and let them sit in the fridge for a day before using.

The whey that is collected during the cheese-making process can be saved and used to make other products like ricotta cheese or bread.

The Cheeses of New York-Style Pizza

You may want to see also

Explore related products

Adding salt and spices

Milk is used to make cheese, but not all types of milk are the same. The type of milk used depends on the type of cheese being made. For example, cow's milk is commonly used to make Swiss, cheddar, and Gouda cheeses because it is widely available and has optimal amounts of fat and protein. On the other hand, sheep's milk is used to make certain types of cheese as well, despite being less commonly consumed as a drink due to its high lactose content. Even more obscure types of milk, such as camel's milk, can be used to make regional specialty cheeses.

Once the type of milk has been chosen, it undergoes a process to transform it into cheese. This process involves adding bacteria or starter cultures to the milk, which eat the lactose sugar and turn it into lactic acid. This increases the acidity of the milk, aiding in curdling, preservation, and flavour development.

After the milk has been transformed into curds and whey, salt is typically added to enhance flavour and regulate moisture content, affecting the texture of the cheese. Salt also serves as a natural preservative, helping to control bacteria growth and aiding in the development of a good rind. The type of salt used is important—cheesemakers usually opt for non-iodized salt or cheese salt as iodine can affect the cheese's flavour and texture. For soft cheeses, a general rule of thumb is to use one teaspoon of salt per half pound of cheese.

When adding salt to the cheese, there are several methods that can be employed. One method, known as direct salting or dry salting, involves sprinkling cut-up curds with salt after the milk has been coagulated, cooked, and drained. This allows for rapid salt absorption and moisture expulsion. Another method involves submerging whole wheels or blocks of cheese in a salty brine solution, resulting in gradual salt penetration and aiding in rind formation. This method is often used for cheeses like mozzarella, blue cheese, some Alpine cheeses, and feta. For smaller cheeses, salt can also be applied to the exterior of already formed wheels or blocks, sometimes scrubbed into the surface.

In addition to salt, spices can be added to cheese to enhance flavour and texture. The method of adding spices depends on the desired result. Ground spices can be mixed into the curd before pressing, resulting in an even distribution of flavour but potentially impacting press quality. Whole spices added directly to the curd can add textural variety and stronger flavour. Spices can also be added to the surface of the cheese, inhibiting the growth of moulds and bacteria. For example, smoked paprika is traditionally used as an outside rub, sometimes mixed with olive oil, while chilli flakes, Tasmanian native pepper, and black pepper are often added to the curds.

Cheese Sauce: Nacho-Style, Which Cheeses Work Best?

You may want to see also

Aging and packaging

While milk is the star ingredient in cheese, the aging process is what gives each cheese its distinct flavour, aroma, and texture. Aging, also known as ripening, is one of the most important elements of the cheese-making process. The aging time varies depending on the type of cheese, ranging from a few months to over a year. For example, softer cheeses like mild cheddar require shorter aging times, while harder cheeses like Parmesan need to be aged for much longer. During the aging process, the cheese develops its full flavour and texture, and in some cases, unique characteristics such as the holes in Swiss cheese.

Once the cheese has reached the desired level of aging, it must be packaged carefully to maintain its quality and extend its shelf life. Cheese is highly sensitive to impact, pressure, temperature, humidity, and ventilation, so proper packaging is essential to protect it from external contaminants. Vacuum-sealed plastic multi-barrier or semi-rigid film is the most common type of cheese packaging as it effectively keeps moisture out and preserves the flavour. It also protects against contamination from other foods and makes storage easier. Other popular packaging options include vertical films, stand-up pouches, and flexible barrier containers made of polypropylene or polyethylene, which provide an oxygen or light barrier for sensitive products like spreadable cheese.

To ensure the cheese's quality and safety, cheese manufacturers must comply with local food safety regulations and invest in advanced packaging solutions. This includes considering the level of automation, floor space, and compatibility with existing machinery. Additionally, determining the appropriate type of packaging material and speed of the packaging process is crucial.

Proper packaging not only maintains product integrity but also helps meet evolving consumer preferences and demands. It is essential for cheese producers to invest in quality packaging equipment to produce safe and consistent products that can be efficiently transported and stored. Overall, the aging and packaging processes are critical steps in the cheesemaking journey, transforming milk into the diverse range of cheeses we know and love.

Cheese Head Screws: Understanding Their Unique Applications

You may want to see also

Frequently asked questions

The milk protein casein and fat are used to make cheese. The milk is coagulated using rennet or an acid, which separates the curds (solids) from the whey (liquid).

Rennet is an enzyme that causes the milk to thicken and form a gel-like consistency, similar to yogurt.

Cow’s milk is the most common type of milk used to make cheese because it is widely available and has optimal amounts of fat and protein. However, cheese can also be made from sheep’s milk, buffalo milk, goat’s milk, camel’s milk, horse milk, and yak’s milk.