When it comes to slicing cheese, choosing the right size motor depends on factors like the type of cheese, desired thickness, and frequency of use. Softer cheeses require less power, while harder varieties like Parmesan or aged cheddar demand a more robust motor to ensure smooth, consistent cuts. Additionally, if you plan to slice cheese frequently or in larger quantities, opting for a motor with higher wattage will provide efficiency and durability. Understanding these considerations will help you select the ideal motor size for your cheese-slicing needs.

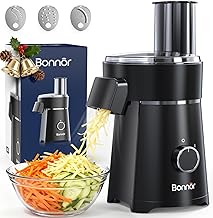

Explore related products

What You'll Learn

- Cheese Type & Hardness: Soft vs. hard cheese requires different motor power for efficient slicing

- Desired Slice Thickness: Thinner slices need precision; thicker slices may require more power

- Motor Speed Options: Variable speeds help control slicing for different cheese textures

- Blade Size & Sharpness: Motor size must match blade efficiency for clean cuts

- Frequency of Use: Occasional vs. heavy use determines motor durability and power needs

Cheese Type & Hardness: Soft vs. hard cheese requires different motor power for efficient slicing

The texture of cheese is a critical factor in determining the motor power needed for efficient slicing. Soft cheeses, such as Brie or Camembert, have a high moisture content and a delicate structure, making them prone to tearing or crumbling under pressure. A motor with lower power, typically ranging from 100 to 200 watts, is sufficient for slicing these cheeses. This power range allows for a controlled and gentle cutting action, preserving the cheese’s integrity while achieving clean slices. For example, a 150-watt motor paired with a thin, sharp blade can effortlessly glide through a wheel of soft cheese without compressing or damaging it.

In contrast, hard cheeses like Parmesan or aged Cheddar demand significantly more power due to their dense, compact nature. These cheeses require a motor in the 300 to 500-watt range to ensure smooth and consistent slicing. Higher wattage motors provide the necessary force to penetrate the cheese’s tough exterior without stalling or overheating. For instance, a 400-watt motor with a serrated blade is ideal for slicing through a block of Parmesan, delivering precise cuts without exerting excessive pressure on the blade or motor.

The relationship between cheese hardness and motor power isn’t just about wattage—blade design also plays a crucial role. Soft cheeses benefit from thin, straight-edged blades that minimize friction, while hard cheeses require thicker, serrated blades to grip and cut through the dense material. Pairing the right blade with the appropriate motor power ensures efficiency and prolongs the life of your slicing equipment. For example, using a high-wattage motor with a thin blade on hard cheese can lead to premature blade wear, while a low-wattage motor with a serrated blade on soft cheese may cause unnecessary tearing.

Practical tips for selecting the right motor power include considering the types of cheese you most frequently slice. If your needs are primarily for soft cheeses, investing in a lower-wattage model with a focus on precision is wise. For a mix of soft and hard cheeses, a mid-range motor (250–350 watts) with interchangeable blades offers versatility. Always ensure the motor has a variable speed setting, as this allows for fine-tuning the cutting action to match the cheese’s hardness. For instance, reducing the speed when slicing semi-soft cheeses like Havarti can prevent smearing, while increasing it for hard cheeses like Pecorino ensures clean cuts.

Ultimately, understanding the interplay between cheese hardness and motor power is key to achieving optimal slicing results. By matching the motor’s capabilities to the cheese’s texture, you can ensure efficiency, preserve the cheese’s quality, and extend the lifespan of your equipment. Whether you’re a home cook or a professional chef, this knowledge empowers you to make informed decisions, turning cheese slicing into a seamless and satisfying task.

Does Leaving Cheese Out Cause Pain? Unraveling the Myth

You may want to see also

Desired Slice Thickness: Thinner slices need precision; thicker slices may require more power

The thickness of your cheese slices dictates the motor size you'll need. For paper-thin slices destined for delicate charcuterie boards or melted atop crackers, precision is paramount. A smaller, high-RPM (revolutions per minute) motor, typically in the 100-200 watt range, paired with a sharp, narrow blade, will deliver the control needed for such finesse. Think of it as a surgeon's scalpel – powerful enough to cut, but precise enough to avoid tearing the delicate cheese.

Think of slicing a young, semi-soft cheese like Brie. A powerful motor would crush its creamy texture. A smaller motor, however, allows for slow, controlled cuts, preserving the cheese's integrity.

Conversely, thicker slices, ideal for hearty sandwiches or grilled cheese masterpieces, demand more power. A motor in the 250-400 watt range, coupled with a wider blade, provides the necessary force to power through denser cheeses like cheddar or Gruyère without bogging down. Imagine slicing through a mature, hard cheese like Parmesan. A weaker motor would struggle, potentially overheating or stalling. A more powerful motor ensures clean, effortless cuts, even through the toughest cheeses.

While motor size is crucial, blade sharpness is equally important. A dull blade, regardless of motor power, will result in ragged, uneven slices. Regular sharpening or blade replacement is essential for optimal performance.

The ideal motor size ultimately depends on your desired slice thickness and the type of cheese you'll be slicing most frequently. For versatility, consider a cheese slicer with adjustable thickness settings, allowing you to adapt to various cheeses and culinary needs. Remember, thinner slices require precision and a smaller motor, while thicker slices demand more power and a larger motor. By understanding this relationship, you can choose the perfect cheese slicer to elevate your culinary creations.

Is Kraft Old English Diced Cheese Real Cheese? Uncovering the Truth

You may want to see also

Motor Speed Options: Variable speeds help control slicing for different cheese textures

Cheese slicing isn't one-size-fits-all. A motor's speed directly impacts the texture and thickness of your slices. Hard cheeses like Parmesan demand a faster blade speed to achieve thin, even shavings without crumbling. Softer cheeses like Brie, however, require a slower speed to prevent tearing and maintain their delicate structure.

Imagine trying to slice through a ripe Camembert with the same speed you'd use for a block of aged Cheddar – disaster.

Variable speed motors offer this crucial control. Think of it like a dimmer switch for your cheese slicer. Lower speeds (around 100-200 RPM) are ideal for soft, creamy cheeses, allowing the blade to gently glide through without compressing or smearing. Medium speeds (300-500 RPM) work well for semi-hard cheeses like Gouda or Swiss, providing a balance between precision and efficiency. For hard cheeses, crank it up to 600 RPM or higher for clean, paper-thin slices.

Some advanced slicers even offer pulse settings, allowing for short bursts of high speed to tackle particularly dense sections without overworking the motor.

The key takeaway? Don't underestimate the power of speed control. It's the difference between a perfectly presented cheese board and a mangled mess. When choosing a motor for cheese slicing, prioritize models with variable speed settings. This simple feature unlocks a world of possibilities, allowing you to handle any cheese texture with confidence and precision.

Exploring Pittsburgh's Philly Cheese Steak Scene: A Restaurant Count

You may want to see also

Explore related products

Blade Size & Sharpness: Motor size must match blade efficiency for clean cuts

The motor size in a cheese slicer isn’t just about power—it’s about precision. A motor that’s too weak struggles with thicker, harder cheeses like Parmesan, resulting in jagged edges or uneven slices. Conversely, an overpowered motor paired with a dull blade wastes energy and risks tearing softer cheeses like Brie. The key lies in balancing motor strength with blade efficiency. For instance, a 100-watt motor paired with a razor-sharp, 8-inch stainless steel blade can effortlessly slice through semi-hard cheeses like Cheddar, while a 50-watt motor with a smaller, serrated blade is ideal for softer varieties.

Consider the blade’s sharpness as the motor’s silent partner. A sharp blade reduces friction, allowing the motor to work less while achieving cleaner cuts. For optimal performance, blades should be honed to a 20-degree angle, a standard used in professional kitchens. Regular maintenance, such as sharpening every 3–6 months depending on usage, ensures the motor doesn’t compensate for dullness by exerting unnecessary force. This not only preserves the motor’s lifespan but also maintains the cheese’s texture and appearance.

When selecting a motor size, factor in the blade’s diameter and material. Larger blades require more torque, so a motor under 150 watts may falter with a 10-inch blade. Stainless steel blades, while durable, demand a motor with consistent power delivery to prevent overheating. For home use, a 75–100 watt motor paired with a 6–8 inch blade strikes a balance between efficiency and versatility. Commercial settings, however, may require motors up to 250 watts to handle high-volume slicing without fatigue.

The interplay between motor size and blade sharpness isn’t just technical—it’s practical. A mismatched setup leads to frustration, waste, and subpar results. For example, using a high-powered motor with a blunt blade on soft cheese like Mozzarella can compress rather than slice, ruining presentation. Conversely, a low-powered motor with a sharp blade may struggle with aged Gouda, causing the blade to bind. The goal is harmony: a motor that complements the blade’s capabilities, ensuring every slice is clean, consistent, and effortless.

To achieve this, start by assessing your cheese-slicing needs. If you primarily work with softer cheeses, prioritize blade sharpness and opt for a smaller motor. For harder varieties, invest in a robust motor paired with a durable, sharp blade. Always test the setup with a sample piece to ensure the motor and blade work in tandem. Remember, the motor’s role is to support the blade, not overpower it. By aligning these components, you’ll achieve professional-quality slices every time, whether for a charcuterie board or a gourmet sandwich.

Queso vs. Nacho Cheese: Unraveling the Melty, Cheesy Mystery

You may want to see also

Frequency of Use: Occasional vs. heavy use determines motor durability and power needs

The frequency of your cheese-slicing endeavors is a critical factor in choosing the right motor size. An occasional cheese slicer, perhaps preparing a charcuterie board for a monthly gathering, can opt for a smaller, less powerful motor. These motors, typically ranging from 100 to 250 watts, are sufficient for slicing softer cheeses like cheddar or mozzarella. They are compact, affordable, and ideal for light-duty tasks, ensuring you don't overspend on a feature you rarely use.

In contrast, heavy-duty cheese slicing demands a more robust solution. Imagine a deli counter, where blocks of cheese are sliced continuously throughout the day. Here, a motor with a power rating of 500 watts or more becomes essential. These high-performance motors can handle harder cheeses, such as Parmesan or aged Gouda, without straining. They are designed for extended use, often featuring overheating protection and durable construction to withstand the rigors of frequent operation.

The key distinction lies in the motor's ability to maintain performance over time. Occasional use allows for shorter bursts of power, while heavy use requires sustained strength and durability. For instance, a 300-watt motor might be adequate for slicing cheese once a week, but it could struggle and overheat if used for an hour daily. This is where the concept of 'duty cycle' becomes relevant—the amount of time a motor can operate continuously before needing a rest period. Heavy-use scenarios demand motors with longer duty cycles, ensuring they can handle the workload without compromising performance or safety.

When considering motor size, it's beneficial to assess your cheese-slicing habits. Are you a home cook preparing cheese platters for special occasions, or do you run a commercial kitchen with high cheese consumption? For the former, a compact, low-power motor is a practical choice, offering ease of use and storage. The latter scenario calls for a more substantial investment in a powerful, heavy-duty motor, ensuring efficiency and longevity in a high-demand environment.

In summary, the frequency of use is a pivotal aspect of motor selection for cheese slicing. It dictates not only the power requirements but also the durability and longevity of the equipment. By understanding your usage patterns, you can make an informed decision, ensuring the motor's capabilities align with your needs, whether it's for occasional cheese platters or high-volume food preparation. This tailored approach guarantees a more satisfying and efficient cheese-slicing experience.

Does the Ozone Layer Contain Ricotta Cheese? Unraveling the Myth

You may want to see also

Frequently asked questions

For home use, a motor with 100 to 200 watts is sufficient for slicing soft to semi-hard cheeses. This power range ensures smooth operation without overheating.

For hard cheeses, a motor with 250 to 350 watts is recommended. The extra power helps handle the density and resistance of harder varieties.

Yes, for commercial use, a motor with 400 watts or more is ideal. This ensures durability, efficiency, and the ability to handle continuous operation and tougher cheeses.

![KWS MS-10NS 320W Motor Electric Meat Slicer 10-Inch with 304 Stainless Steel Blade, Frozen Meat/Cheese/Food Slicer Low Noise Commercial and Home Use [ ETL, NSF Certified ]](https://m.media-amazon.com/images/I/71wz7DaA7mL._AC_UY218_.jpg)

![KWS MS-10NT 320W Motor Electric Meat Slicer 10-Inch with 304 Stainless Steel coated with Teflon Blade, Frozen Meat/Cheese/Food Slicer Low Noise Commercial and Home Use [ ETL, NSF Certified ]](https://m.media-amazon.com/images/I/5180do6m-mL._AC_UY218_.jpg)