When hauling cheese, setting the refrigerator at the correct temperature is crucial to maintain its quality and safety. Cheese is a perishable product that requires specific storage conditions to prevent spoilage and preserve its flavor and texture. The ideal temperature for transporting cheese typically ranges between 35°F and 40°F (2°C to 4°C), depending on the type of cheese. Harder cheeses like cheddar or Parmesan can tolerate slightly higher temperatures, while softer cheeses such as Brie or Camembert require cooler conditions. Proper temperature control ensures that the cheese remains fresh, minimizes the risk of bacterial growth, and avoids undesirable changes in taste or consistency during transit.

Explore related products

What You'll Learn

- Optimal Cheese Storage Temps: Ideal range to maintain cheese quality during transport

- Hard vs. Soft Cheese Temps: Different cheeses require specific temperature settings

- Refrigeration Unit Calibration: Ensuring the unit accurately maintains the set temperature

- Temperature Monitoring Tools: Devices to track and log temps during hauling

- Seasonal Adjustments: How weather conditions impact refrigeration settings for cheese transport

Optimal Cheese Storage Temps: Ideal range to maintain cheese quality during transport

Maintaining the right temperature is critical when hauling cheese, as fluctuations can compromise its texture, flavor, and safety. The ideal range for most cheeses during transport is 40°F to 45°F (4°C to 7°C). This range prevents bacterial growth while preserving moisture and structural integrity. Hard cheeses like cheddar or Parmesan are more forgiving, tolerating slightly higher temps up to 50°F (10°C), but softer varieties like Brie or mozzarella require stricter adherence to the lower end of the spectrum. Always pre-cool the reefer unit before loading to ensure immediate temperature stability.

Consider the cheese’s age and moisture content when fine-tuning the temperature. Younger, higher-moisture cheeses (e.g., fresh mozzarella or goat cheese) are more susceptible to spoilage and should be kept closer to 40°F (4°C). Aged, harder cheeses can handle slightly warmer conditions but still benefit from consistent cooling. Use digital thermometers to monitor the reefer’s internal temperature and avoid placing cheese near vents or doors, where temperature fluctuations are more likely. Insulated packaging or coolers can provide an extra layer of protection for sensitive varieties.

Humidity control is equally important, as cheese is a living product that breathes. Aim for a relative humidity of 80% to 85% to prevent drying or mold growth. If the reefer unit lacks humidity control, wrap cheese in wax paper or cheesecloth before placing it in airtight containers. Avoid plastic wrap, which traps moisture and accelerates spoilage. For long hauls, invest in a reefer unit with dual-zone temperature and humidity controls to accommodate different cheese types simultaneously.

Finally, plan for contingencies. If the reefer unit malfunctions, have backup cooling methods like dry ice or gel packs ready. Keep a log of temperature readings at regular intervals to identify issues early. For cross-border hauls, research local regulations, as some regions have specific temperature requirements for dairy products. Proper preparation and monitoring ensure that cheese arrives in optimal condition, preserving its quality and value for the end consumer.

Wisconsin's Cheese Legacy: Counting the State's Iconic Factories

You may want to see also

Hard vs. Soft Cheese Temps: Different cheeses require specific temperature settings

Cheese, a delicate yet diverse food, demands precise temperature control during transportation to preserve its quality. The ideal refrigerator setting isn’t one-size-fits-all; it hinges on whether you’re hauling hard or soft cheeses. Hard cheeses, like Parmesan or Cheddar, thrive at slightly warmer temperatures (45°F to 50°F) compared to their softer counterparts. This range maintains their texture without drying them out, ensuring they remain firm yet flavorful upon arrival.

Soft cheeses, such as Brie or Camembert, require a cooler environment (35°F to 40°F) to prevent spoilage and maintain their creamy consistency. These cheeses are more perishable due to higher moisture content, making temperature control critical. Even a slight deviation can lead to mold growth or texture degradation. For example, storing Brie at 50°F for more than a few hours can turn its velvety interior into a runny mess.

When hauling both types simultaneously, compartmentalize your cooler or refrigerator to maintain distinct zones. Use separate containers or dividers to prevent cross-contamination and temperature fluctuations. For instance, place hard cheeses in the warmer section of the fridge, often the middle shelf, while soft cheeses should occupy the coldest area, typically the bottom shelf or a dedicated drawer.

Practical tips include monitoring temperatures with a portable thermometer, especially during long hauls. Insulated coolers with ice packs can serve as a backup if refrigeration isn’t available. For aged hard cheeses, like Parmesan, slight temperature variations are more forgiving, but softer varieties demand stricter adherence to their ideal range. Always check the cheese’s packaging for manufacturer recommendations, as some varieties may have specific storage needs.

In summary, understanding the temperature requirements of hard versus soft cheeses is essential for successful transportation. Hard cheeses fare well at 45°F to 50°F, while soft cheeses need the cooler 35°F to 40°F range. By implementing proper storage practices and staying vigilant, you can ensure every cheese arrives in peak condition, ready to delight palates.

Yogurt vs. Cheese: Culturing Techniques and Key Differences Explained

You may want to see also

Refrigeration Unit Calibration: Ensuring the unit accurately maintains the set temperature

Maintaining the correct temperature is critical when hauling cheese, as fluctuations can compromise quality, texture, and safety. Cheese is a perishable product, and its optimal storage temperature varies by type: hard cheeses like cheddar thrive at 35°–40°F (2°–4°C), while soft cheeses like brie require 45°–50°F (7°–10°C). However, setting the refrigeration unit to these temperatures isn’t enough; the unit must *accurately maintain* them, which is where calibration becomes essential. Without precise calibration, even a 2°F deviation can accelerate spoilage or alter flavor profiles, turning a premium product into a costly loss.

Calibration begins with verifying the unit’s temperature accuracy using a certified thermometer placed in the center of the cargo area. If the unit reads 38°F but the thermometer shows 42°F, the system is off by 4°F—a critical discrepancy for cheese. Adjust the unit’s setpoint accordingly, but avoid relying solely on the manufacturer’s controls. External factors like ambient temperature, humidity, and cargo load can skew performance, so recalibrate before each haul. For example, a fully loaded trailer may require a slightly lower setpoint to account for heat generated by the cheese itself.

Regular maintenance is equally vital to ensure calibration holds over time. Clean evaporator coils and condenser units monthly to prevent dust buildup, which can reduce efficiency by up to 30%. Inspect door seals for cracks or tears, as even small gaps allow warm air to infiltrate, forcing the unit to work harder and increasing the risk of temperature drift. For units with digital controls, update firmware annually to address known issues and improve accuracy. Neglecting these steps can render calibration efforts useless, leaving cheese vulnerable to temperature abuse.

Advanced units with automated defrost cycles and temperature logging offer additional safeguards. These systems record data at 15-minute intervals, providing a historical record to identify trends or anomalies. For instance, if logs show repeated spikes during nighttime hours, investigate whether the unit’s defrost cycle is malfunctioning or if external power sources are fluctuating. Addressing such issues promptly ensures the unit maintains the set temperature consistently, preserving cheese quality from farm to table.

Finally, train personnel to recognize signs of improper calibration, such as condensation on cheese packaging or unusual odors, which indicate temperature instability. Establish a pre-trip checklist that includes verifying the unit’s calibration, testing backup power systems, and confirming the setpoint aligns with the cheese type being hauled. By treating calibration as a dynamic, ongoing process rather than a one-time task, haulers can safeguard their cargo, protect their reputation, and maximize profitability in the competitive dairy logistics sector.

Cheese's Energy Powerhouse: Unveiling the Nutrient with Maximum Caloric Impact

You may want to see also

Explore related products

Temperature Monitoring Tools: Devices to track and log temps during hauling

Maintaining the correct temperature is critical when hauling cheese, as fluctuations can compromise quality, texture, and safety. Cheese should be transported at temperatures between 35°F and 45°F (2°C and 7°C), depending on the type. For example, hard cheeses like cheddar tolerate slightly higher temps, while soft cheeses like brie require the lower end of the range. To ensure compliance, temperature monitoring tools are indispensable. These devices not only track real-time conditions but also log data for traceability and regulatory compliance.

Types of Temperature Monitoring Devices

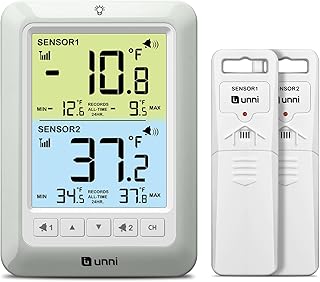

Digital data loggers are the gold standard for hauling cheese. These compact devices record temperature at set intervals, often with USB connectivity for easy data transfer. For instance, the EL-USB-1 model logs temps every 10 seconds and stores up to 16,000 readings, ideal for long hauls. Wireless sensors paired with smartphone apps offer real-time alerts, such as the TempCube Pro, which notifies drivers if temperatures deviate from the 35°F–45°F range. For budget-conscious haulers, single-use indicators like SpotSee’s ColdMark provide a cost-effective solution, though they lack data logging capabilities.

Key Features to Look For

When selecting a monitoring tool, prioritize accuracy (±1°F or better), battery life (at least 30 days for long hauls), and durability to withstand vibrations and temperature extremes. Waterproof designs are essential for refrigerated trucks prone to condensation. Cloud-based systems, like the Track-It system, offer remote monitoring, allowing fleet managers to intervene if temps spike. Calibration certificates are a must for devices used in regulated industries, ensuring compliance with FDA or USDA standards.

Practical Tips for Implementation

Place sensors at multiple points within the trailer—near the door, center, and rear—to account for temperature gradients. Secure devices with magnetic mounts or zip ties to prevent shifting during transit. Regularly download and analyze logged data to identify patterns, such as consistent hot spots, and adjust hauling practices accordingly. For example, pre-cooling the trailer 24 hours before loading can stabilize temps faster. Train drivers to respond to alerts promptly, such as rerouting to a cooler facility if temps exceed 45°F for more than 30 minutes.

Future Trends and Innovations

Emerging technologies like IoT-enabled sensors and AI-driven analytics are revolutionizing temperature monitoring. Systems like Samsara integrate GPS, temperature tracking, and predictive maintenance into a single platform, offering actionable insights to optimize hauling routes. Blockchain-based logging is also gaining traction, providing immutable records for food safety audits. While these advancements come with higher upfront costs, they reduce long-term risks of spoilage and regulatory fines, making them a smart investment for cheese haulers.

By leveraging the right tools and strategies, haulers can ensure cheese arrives in pristine condition, preserving both quality and reputation.

Decoding Expiration Dates on Kraft Cheese: A Simple Guide

You may want to see also

Seasonal Adjustments: How weather conditions impact refrigeration settings for cheese transport

Cheese, a delicate cargo, demands precise temperature control during transport, and this becomes even more critical when considering the impact of seasonal weather fluctuations. The ideal refrigeration settings for cheese hauling are not static; they require seasonal adjustments to ensure the product's quality and safety. As temperatures rise in the summer months, the challenge lies in maintaining a cool environment within the trailer to prevent cheese from spoiling or developing unwanted characteristics.

The Summer Challenge: Beating the Heat

Instructively, during summer, the goal is to create a microclimate within the trailer that counters the external heat. The recommended temperature range for most cheeses during transport is between 2°C and 8°C (35°F and 46°F). However, when ambient temperatures soar, achieving this range becomes a delicate balance. Here's a strategic approach: set the refrigeration unit to maintain a temperature of 4°C (39°F) at the start of the journey. This initial setting accounts for the cooling-down period and ensures the cheese doesn't experience a rapid temperature drop, which could cause condensation and affect its texture. As the trip progresses, monitor the external temperature and adjust the refrigeration settings accordingly, allowing for a gradual increase to 6°C (43°F) if the outside heat becomes more intense.

Winter's Dilemma: Avoiding the Freeze

In contrast, winter presents a different set of challenges. Persuasively, one might assume that colder external temperatures would simplify cheese transportation, but this is a common misconception. While the risk of spoilage decreases, the potential for freezing becomes a significant concern. Hard cheeses, such as Cheddar or Parmesan, can withstand colder temperatures, but soft cheeses like Brie or Camembert are highly susceptible to texture and flavor alterations when frozen. To navigate this, consider a two-pronged strategy. Firstly, insulate the trailer to minimize the impact of external cold, especially during prolonged stops. Secondly, set the refrigeration unit to a slightly higher temperature, around 10°C (50°F), to create a buffer against freezing conditions.

The Art of Adjustment: A Comparative Approach

Comparatively, the key to successful cheese transport lies in understanding the unique requirements of different cheese varieties and their sensitivity to temperature variations. For instance, fresh cheeses like Mozzarella or Ricotta are highly perishable and require stricter temperature control, ideally at the lower end of the spectrum, around 2°C (35°F). In contrast, aged cheeses, such as Gouda or Gruyère, are more forgiving and can tolerate a broader temperature range, typically between 4°C and 10°C (39°F and 50°F). By categorizing cheeses based on their sensitivity, haulers can implement tailored temperature settings, ensuring each type receives the appropriate care.

Practical Tips for Year-Round Success

Descriptively, imagine a scenario where a hauler is transporting a mixed load of cheeses across varying climates. The journey begins in a warm region, requiring the initial summer strategy, but as the route progresses, the weather turns colder. In this case, a dynamic approach is essential. Start with the summer settings, gradually adjusting as the temperature drops, and be prepared to implement winter strategies if necessary. Regularly monitor the cheese's condition, especially during extended hauls, and keep detailed records of temperature settings and external conditions. This data-driven approach allows for informed adjustments and ensures the cheese arrives in optimal condition, regardless of the season.

In the world of cheese transportation, seasonal adjustments are an art, requiring a deep understanding of both the product and the environment. By implementing these strategies, haulers can ensure that cheese lovers everywhere receive their favorite dairy delight in perfect condition, no matter the weather.

Sargento Balanced Breaks Cheese Portions: Ounces Per Pack Explained

You may want to see also

Frequently asked questions

Set the refrigerator temperature between 35°F and 40°F (2°C and 4°C) to keep cheese fresh and prevent spoilage during transport.

Yes, softer cheeses like Brie or Camembert may require slightly higher temps (around 45°F or 7°C), while harder cheeses like Cheddar or Parmesan can handle 35°F to 40°F (2°C to 4°C).

Cheese can remain at the recommended temperature for up to 48 hours without significant quality loss, but it’s best to minimize transport time for freshness.

If the temperature exceeds 50°F (10°C), cheese can spoil, develop bacteria, or lose texture and flavor. Always monitor and maintain proper cooling.

Yes, using a reliable thermometer is essential to ensure the refrigerator stays within the optimal temperature range and to avoid spoilage.