When making farmers cheese, the temperature of the milk is a critical factor in achieving the desired curdling and texture. Generally, the milk should be heated to a temperature between 80°F to 90°F (27°C to 32°C) before adding the acid (such as lemon juice or vinegar) or rennet. This gentle warmth helps activate the enzymes and encourages the milk to curdle effectively without scorching or altering the milk’s proteins. Maintaining this temperature range ensures a smooth, creamy consistency in the final cheese, making it ideal for spreading or crumbling. It’s important to monitor the temperature closely, as overheating can lead to a grainy or rubbery texture.

Explore related products

$9.34 $10.99

What You'll Learn

Ideal Milk Temperature Range

The ideal temperature range for milk when making farmer’s cheese is a delicate balance, typically falling between 72°F and 86°F (22°C to 30°C). This range is crucial because it activates the enzymes in the milk and allows the culture to work effectively, promoting proper curdling. Too cold, and the culture remains dormant; too hot, and you risk denaturing proteins or killing beneficial bacteria. This window is your sweet spot for achieving the right texture and flavor in your cheese.

Analyzing the science behind this range reveals why precision matters. At 72°F (22°C), mesophilic cultures, commonly used in farmer’s cheese, begin to ferment lactose into lactic acid, a process essential for curd formation. As the temperature approaches 86°F (30°C), the culture’s activity accelerates, but beyond this point, the milk’s proteins can coagulate unevenly, leading to a grainy or rubbery texture. For raw milk, this range is particularly critical, as higher temperatures can destroy natural enzymes and alter the cheese’s character. Pasteurized milk, however, is more forgiving but still benefits from staying within this optimal zone.

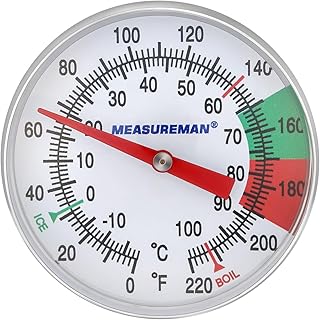

To achieve this temperature range, start by heating the milk slowly, using a thermometer to monitor progress. A double boiler or a pot over low heat works well to prevent overheating. If the milk exceeds 86°F (30°C), let it cool slightly before adding the culture. For those without a thermometer, observe the milk’s surface—tiny bubbles forming around the edges indicate it’s nearing the ideal range. Once the desired temperature is reached, immediately add the culture and maintain the heat consistently for best results.

Comparing this process to other cheese-making methods highlights its simplicity. Unlike hard cheeses, which often require higher temperatures and longer aging, farmer’s cheese is a beginner-friendly option that relies heavily on this initial temperature control. Its quick turnaround—often ready in a few hours—makes it a rewarding project for home cheesemakers. However, the temperature range remains non-negotiable, as even slight deviations can impact the final product’s quality.

In practice, mastering this temperature range is a skill honed through repetition. Keep a log of temperatures and outcomes to refine your technique. For example, if your cheese turns out too soft, try starting at the lower end of the range (72°F/22°C). Conversely, if it’s too firm, aim closer to 86°F (30°C). Small adjustments within this range can yield significant improvements, turning a good batch of farmer’s cheese into a great one. With patience and attention to detail, you’ll soon intuit the milk’s behavior and produce consistently excellent results.

We Are Chalk and Cheese": Unraveling the Meaning Behind the Expressio

You may want to see also

Heating Milk Gradually Tips

Heating milk gradually is crucial for making farmer’s cheese, as abrupt temperature changes can scorch the milk or cause uneven curdling. The ideal temperature range for farmer’s cheese is between 70°F to 86°F (21°C to 30°C), depending on the recipe and desired curd texture. This gentle warming process activates enzymes in the milk, encouraging proper coagulation without damaging its proteins. Rushing this step risks a grainy or rubbery final product, so patience is key.

To heat milk gradually, start by placing it in a heavy-bottomed saucepan over low heat. Stir constantly to distribute warmth evenly and prevent hot spots, which can cause localized curdling. Use a reliable thermometer to monitor the temperature, aiming for a steady increase of 2°F to 3°F per minute. If you don’t have a thermometer, observe the milk’s surface—tiny bubbles forming around the edges indicate it’s nearing the target range. Avoid letting it simmer or boil, as temperatures above 180°F (82°C) will denature the proteins and ruin the cheese-making process.

Comparing methods, heating milk in a double boiler offers more control but takes longer, while direct stovetop heating is faster but riskier. For beginners, the double boiler method is recommended, as it minimizes the chance of overheating. If using a stovetop, reduce the heat to its lowest setting and remove the pan briefly if the temperature climbs too quickly. Adding a small amount of cold milk can help stabilize the temperature if it rises unexpectedly.

A practical tip is to pre-warm the milk to room temperature before heating, as starting with cold milk from the refrigerator increases the risk of uneven warming. This can be done by leaving the milk on the counter for 30 to 60 minutes or submerging the container in warm water for 10 to 15 minutes. Once heated, maintain the milk at the target temperature for 5 to 10 minutes to ensure the enzymes are fully activated, then proceed with adding the coagulant (e.g., vinegar or rennet) for curdling.

In conclusion, heating milk gradually for farmer’s cheese requires precision, attention, and the right tools. By controlling the temperature and using techniques like stirring and pre-warming, you can achieve the ideal conditions for curd formation. Mastering this step not only ensures a smooth, creamy cheese but also builds a foundation for more advanced cheese-making endeavors.

Can You Bring Cheese to the USA? Travel Rules Explained

You may want to see also

Thermometer Use for Accuracy

Achieving the precise temperature for milk when making farmer’s cheese is critical, as even slight deviations can affect curdling and texture. A thermometer isn’t just a tool—it’s your safeguard against guesswork. Most recipes call for heating milk to 180°F (82°C) to denature proteins and prepare for acid or rennet addition. Without a thermometer, you’re relying on visual cues like steam or bubbling, which are inconsistent and risk overheating. This small investment in accuracy ensures your cheese sets properly, avoiding a grainy or rubbery result.

Consider the types of thermometers available: instant-read digital thermometers offer speed and precision, while candy/deep-fry thermometers are durable for prolonged heating. Avoid glass thermometers, as they’re fragile and slower to respond. For farmer’s cheese, clip your thermometer to the side of the pot, ensuring the tip is submerged in milk but not touching the bottom, which can give false readings. Stir occasionally to distribute heat evenly, and watch for the temperature to stabilize before proceeding. This method eliminates the ambiguity of "warm" or "hot," replacing it with actionable data.

Accuracy isn’t just about hitting 180°F—it’s also about controlling the cooling process. After adding acid (like lemon juice or vinegar), the milk should cool to around 110°F (43°C) for optimal curd formation. A thermometer allows you to monitor this drop, preventing the mixture from cooling too quickly or slowly. Without this precision, curds may be too soft or fail to separate from whey. Think of the thermometer as your compass, guiding each stage of the process with scientific certainty.

For beginners, practice makes perfect. Start by calibrating your thermometer in boiling water (212°F/100°C at sea level) to ensure it’s reliable. During heating, avoid distractions—temperatures can rise rapidly, especially in smaller batches. If using raw milk, pasteurize it by holding it at 145°F (63°C) for 30 minutes before proceeding, a step where a thermometer is indispensable. Advanced cheesemakers might experiment with slightly lower temperatures (175°F/79°C) for a milder flavor, but this requires even greater precision. The takeaway? A thermometer transforms cheese-making from an art into a repeatable science.

Finally, cleanliness is as vital as accuracy. Wash your thermometer before and after use to prevent cross-contamination, especially if switching between dairy and non-dairy ingredients. Store it properly to avoid damage, as a cracked or malfunctioning thermometer can ruin a batch. By treating this tool with respect and integrating it into your process, you’ll consistently produce farmer’s cheese with the ideal texture and flavor. It’s not just about following a recipe—it’s about mastering the variables that define success.

Brand Cheese Battle: Uncovering the Real Differences in Quality and Taste

You may want to see also

Explore related products

Avoiding Overheating Milk

Milk's delicate proteins and fats demand precision in temperature control when crafting farmer's cheese. Overheating milk can lead to a grainy texture, reduced yield, and off-flavors. The ideal temperature range for coagulation in farmer's cheese production is 70–80°F (21–27°C). At this range, the rennet or acid coagulant works efficiently without denaturing the milk’s proteins. Exceeding 85°F (29°C) risks tightening the curds too quickly, expelling whey prematurely and hardening the final product.

Consider the process as a delicate dance: too much heat, and the curds become brittle; too little, and they fail to set. For home cheesemakers, using a digital thermometer is non-negotiable. Analog thermometers can lag or misread, leading to accidental overheating. Stir the milk gently while heating to distribute warmth evenly, and remove it from the heat source just before reaching the target temperature, as residual heat will continue to raise the temperature slightly.

A common mistake is rushing the heating process. Patience is key. Heat milk gradually, no faster than 2°F (1°C) per minute, to maintain control. If using a stovetop, opt for low heat and monitor constantly. Alternatively, a water bath method—placing the milk container in warm water—offers more stability. For larger batches, pre-warming the milk to room temperature (68°F/20°C) before heating reduces the risk of uneven temperature spikes.

Overheating isn’t just about temperature—it’s also about duration. Prolonged exposure to even moderate heat can degrade milk’s structure. Once the milk reaches 80°F (27°C), immediately add the coagulant and cease heating. Covering the pot with a lid retains warmth without further cooking. If the milk does overheat, there’s no salvaging the batch for farmer’s cheese; instead, use it for ricotta or baked goods, where texture is less critical.

Finally, environmental factors play a role. Humidity and room temperature influence how quickly milk heats. In warmer climates, work in a cooler space or during cooler hours. Conversely, in colder environments, ensure the milk doesn’t cool below 68°F (20°C) before adding the coagulant. Mastery of temperature control transforms farmer’s cheese from a gamble into a consistent, creamy delight.

Mastering Transformice: Proven Strategies to Earn Tons of Cheese Fast

You may want to see also

Cooling Milk Post-Curdling Steps

After curdling, the milk for farmer’s cheese must be cooled strategically to preserve texture and flavor. The ideal temperature range post-curdling is 100–110°F (38–43°C). This controlled cooling prevents the curds from becoming too tough or releasing excess whey prematurely. Lower temperatures risk hardening the curds, while higher ones can cause them to dissolve. The goal is to maintain a gentle heat that allows the curds to expel whey gradually without overcooking.

The cooling process begins immediately after cutting the curd. Stir the mixture gently for 2–3 minutes to distribute heat evenly, ensuring no hot spots form. Then, reduce the heat to low or remove the pot from direct heat, depending on your setup. For precision, use a thermometer to monitor the temperature, adjusting as needed. If the milk drops below 100°F, return it to low heat briefly to stabilize. This step is critical for achieving the creamy, crumbly texture characteristic of farmer’s cheese.

A common mistake is rushing the cooling process by adding cold water or ice. This shocks the curds, causing them to tighten and expel too much whey, resulting in a dry, rubbery product. Instead, allow the curds to rest in the warm liquid for 5–10 minutes, letting them firm up naturally. During this time, the curds will shrink slightly and release whey at an optimal rate. Patience here pays off, as it ensures the curds retain moisture and structure.

For those using raw milk, cooling post-curdling requires extra attention. Raw milk curds are more delicate and can easily overheat. Keep the temperature at the lower end of the range (100°F) and monitor closely. If using pasteurized milk, the curds are more forgiving but still benefit from gradual cooling. Regardless of milk type, the key is consistency—small, steady adjustments yield better results than abrupt changes.

In summary, cooling milk post-curdling is a delicate balance of temperature and timing. Aim for 100–110°F, stir gently, and avoid rapid cooling methods. This approach ensures the curds remain tender and whey is expelled evenly, setting the stage for a perfect batch of farmer’s cheese. Master this step, and you’ll elevate both the texture and flavor of your final product.

Does Food Lion Brand Cheese Contain Pork Enzymes? Find Out Here

You may want to see also

Frequently asked questions

The ideal temperature for milk when making farmer's cheese is between 80°F to 85°F (27°C to 29°C). This range allows the cultures and rennet to work effectively without overheating the milk.

Heating milk above 85°F (29°C) can denature the proteins and kill the cultures, preventing proper curdling. It’s best to stay within the recommended range for optimal results.

If the milk is too cold, the cultures may not activate properly, and the curdling process will be slow or incomplete. Always warm the milk to the recommended temperature before adding cultures and rennet.

Use a thermometer to monitor the temperature and keep the milk in a warm, stable environment, such as a water bath or a preheated pot, to maintain the desired temperature throughout the process.

Yes, the milk temperature significantly affects the texture. Too high a temperature can result in a tough, rubbery cheese, while too low a temperature can lead to a soft, crumbly texture. Maintaining the correct temperature ensures a smooth, creamy consistency.

![Cow Milk LDH Test Strips for Mastitis Detection [Vial of 50 Tests]](https://m.media-amazon.com/images/I/515JmXqlOsL._AC_UL320_.jpg)