Calcium Chloride is a salt solution that is added to milk to restore balance to the calcium content and improve coagulation. It is often used in cheese-making to produce a firmer curd that is easier to cut and results in a larger yield. While it is commonly added to store-bought milk, it can also be used with goat's milk, particularly when making hard cheeses. The addition of Calcium Chloride to goat's milk helps to firm up the curd and increase the yield by boosting the number of calcium ions in the milk. However, some cheesemakers choose not to use it, especially with raw goat's milk, as it may not always be necessary to achieve a satisfactory curd.

When to use Calcium Chloride in Goat Cheese

| Characteristics | Values |

|---|---|

| Why use Calcium Chloride | To restore balance to the calcium content of milk that has been heat-treated and homogenized |

| When to use | Before adding rennet |

| How to use | Dilute in cool, distilled water and stir through the milk |

| How much to use | 1/4 teaspoon per gallon of milk |

| Goat's milk | Goat's milk is naturally homogenized and may produce a weak curd without Calcium Chloride |

| Goat's diet | A good diet with supplementation may result in strong curds without Calcium Chloride |

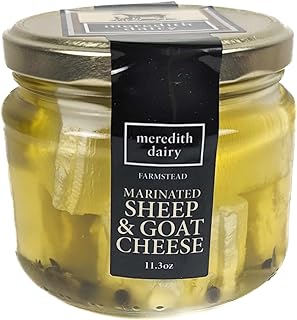

Explore related products

What You'll Learn

Calcium Chloride is not always necessary when making goat cheese

Calcium Chloride is commonly used to rebalance the calcium content in store-bought, homogenized, and pasteurized milk. The processes of pasteurization, heating, rapid cooling, and homogenization can decrease the amount of calcium in the milk, affecting its clotting properties. As a result, the milk may exhibit slower coagulation after adding Rennet and produce a softer, less stable curd. However, these issues may not be present in raw goat's milk, eliminating the need for Calcium Chloride.

Some cheese makers have reported successful goat cheese production without using Calcium Chloride. They have achieved adequate curd formation and texture without experiencing any negative long-term effects. It is important to note that the curd produced without Calcium Chloride may be softer compared to cow's milk or water buffalo's milk curd.

The decision to use Calcium Chloride ultimately depends on the specific circumstances and preferences of the cheese maker. If one is using raw goat's milk of good quality, obtained from a well-cared-for goat with a healthy diet, Calcium Chloride may not be necessary. However, if the milk supply yields a weak curd, adding Calcium Chloride can be a remedy to firm up the curd and increase the yield.

In summary, while Calcium Chloride is often suggested when making goat cheese, particularly for hard cheeses, it is not an indispensable ingredient. Cheese makers can experiment with and without Calcium Chloride to determine the best approach for their specific situation and desired cheese characteristics.

Goat Cheese Delights: Creative Uses for Frozen Treats

You may want to see also

It is recommended when making hard cheeses

Calcium Chloride is recommended when making hard goat cheeses. Goat's milk goes through a natural homogenization process in the animal's body, which can result in a curd that is too soft and weak to cut properly. The addition of Calcium Chloride helps to strengthen the curds, making them firmer and easier to cut. It also boosts yield and improves milk coagulation, resulting in a higher-quality cheese.

The recommended amount of Calcium Chloride is 1/4 teaspoon per gallon of milk, added to the milk before starting the cheese-making process. Some cheesemakers even add it to the milk the night before to allow ample time for it to rebalance the calcium content. This step is crucial in restoring balance to the calcium levels in the milk, which may have been decreased due to pasteurization, heating, rapid cooling, and homogenization processes.

However, it's important to note that not all cheesemakers agree on the necessity of Calcium Chloride. Some claim that if goats have access to "plenty of browse," their milk will naturally produce strong curds without the need for Calcium Chloride. Additionally, Calcium Chloride should not be used when making mozzarella, as it can prevent the curds from stretching.

Ultimately, the decision to use Calcium Chloride depends on various factors, including the quality of milk, the desired firmness of the curd, and the type of cheese being made. While it is recommended for hard goat cheeses, it may not be necessary for all cheesemakers or cheese varieties.

By adding Calcium Chloride to the milk before beginning the cheese-making process, cheesemakers can produce a higher-quality hard goat cheese with firmer, more manageable curds and increased yield.

Goat Cheese: A Sour Surprise?

You may want to see also

It can be added to the milk the night before

Calcium Chloride is added to goat's milk to restore balance to the calcium content of the milk. Goat's milk goes through a natural homogenization process in the animal's body, and without Calcium Chloride, it may produce a curd that is too weak to cut. The manufacturing processes of pasteurization, heating, and rapidly cooling the milk can also decrease the amount of calcium in the milk.

Calcium Chloride is usually added to the milk before starting the cheese-making process. Some cheesemakers prefer to add it to the milk in the stockpot the night before making the cheese. This allows plenty of time for the Calcium Chloride to rebalance the calcium content of the milk before starting the cheese-making process.

The recommended measure is 1/4 teaspoon of Calcium Chloride per gallon of milk. To add Calcium Chloride, dilute it in 1/4 cup of cool, distilled water, and then stir it evenly through the milk. This can be done the night before making the cheese, giving the Calcium Chloride time to work and rebalance the calcium content of the milk.

Adding Calcium Chloride to goat's milk before making cheese is a common practice, especially when using store-bought, pasteurized, or homogenized milk. It helps produce a firmer curd that is easier to cut and results in a higher yield. However, some cheesemakers may not need to add Calcium Chloride if their goats have access to "plenty of browse" or high-quality feed, resulting in strong curds without the need for additional Calcium Chloride.

Goat Cheese: Pasteurization Process and Benefits Explained

You may want to see also

Explore related products

It boosts the number of calcium ions in the milk

Calcium Chloride is a salt solution that helps restore the calcium content of milk. It is typically added to store-bought, pasteurized, and homogenized milk, which tends to have lower calcium levels due to the manufacturing processes involved. This process of pasteurization, rapid heating and cooling, and homogenization can decrease the amount of calcium in the milk, affecting its clotting properties.

Goat's milk, in particular, can benefit from the addition of Calcium Chloride, especially when making hard cheeses. Goat's milk naturally undergoes a homogenization process in the animal's body, and without Calcium Chloride, the resulting curd may be too soft or weak to cut properly. The fine fat particles in goat's milk stay in suspension instead of separating, as in cow's milk, which further emphasizes the importance of Calcium Chloride in the cheese-making process.

By adding Calcium Chloride, you boost the number of calcium ions in the milk, which helps to firm up the curd. This results in a higher yield of cheese, making it a desirable step when making goat's milk cheeses. The recommended measure is 1/4 teaspoon of Calcium Chloride diluted in 1/4 cup of cool, distilled water per gallon of milk. This mixture is then added to the milk before starting the cheese-making process, allowing it to re-balance the calcium content.

It is worth noting that some cheesemakers have achieved satisfactory results without using Calcium Chloride, especially with raw or farm-fresh goat's milk. The diet and health of the animals, as well as the lactation stage, can influence the calcium levels in the milk. However, the majority of cheesemakers, especially those using store-bought milk, find that Calcium Chloride improves the coagulation process and results in a firmer and more workable curd.

Goat Cheese and Spices: Perfect Pairings for Your Palate

You may want to see also

It strengthens curds and increases yield

Calcium Chloride (CaCI2) is a salt solution that helps to restore balance to the calcium content of milk. The processes of pasteurisation, heating, rapid cooling, and homogenisation decrease the amount of calcium in the milk, which can affect the clotting properties and result in a softer, less stable curd.

Goat's milk, for example, is lower in calcium than cow's milk. The diet of the animal can also affect the milk's calcium content; for instance, if the goat has been eating young grass in the spring, which is low in minerals.

Adding Calcium Chloride to your milk brings the calcium content back into balance and will result in a firmer curd, which is easier to cut and produces a larger yield. It strengthens the protein molecules in the milk, boosting the yield of cheese by as much as 2-3%. It is usually added to the milk before starting the cheese-making process, and some cheesemakers add it the night before to give it more time to work.

However, some cheesemakers do not use Calcium Chloride at all, even with goat's milk. One source states that if goats have "plenty of browse," their curds will be strong without it. Another source says that Calcium Chloride is unnecessary if you are using raw milk, as it is already firm enough to cut without it.

Goat Cheese Alternatives: Exploring Delicious Substitutes

You may want to see also

Frequently asked questions

Calcium Chloride is added to goat's milk to strengthen the curds, boost yield, and improve milk coagulation for better cheese results. It is required to re-balance the calcium content of milk as pasteurization, heating, and rapid cooling of the milk decrease the amount of calcium in the milk and can affect the clotting properties.

Calcium Chloride is normally added to the milk before starting the cheese-making process. Some cheesemakers even prefer to add it to the milk in the stockpot the night before making the cheese so that it has plenty of time to work on re-balancing the calcium content.

The recommended measure is 1/4 teaspoon of calcium chloride for every gallon of milk.