Cheese wheels are brushed as part of a meticulous aging process known as affinage, which helps maintain their quality, texture, and flavor. Brushing removes surface mold, bacteria, and excess moisture that can accumulate during aging, preventing unwanted spoilage and ensuring a clean, even rind. Additionally, brushing encourages the growth of desirable molds and bacteria that contribute to the cheese's unique characteristics, such as its aroma and taste. This practice also helps to distribute natural salts and fats across the rind, promoting proper ripening and protecting the cheese from drying out or cracking. Regular brushing is essential for crafting high-quality cheeses, particularly in traditional and artisanal production methods.

| Characteristics | Values |

|---|---|

| Purpose | To promote rind development, prevent mold growth, and enhance flavor |

| Frequency | Regularly, often daily or every few days during aging |

| Tools Used | Natural bristle brushes, cloth, or specialized cheese brushes |

| Substances Applied | Saltwater, brine, wine, beer, or other solutions to encourage specific rind types |

| Benefits | Encourages beneficial bacteria and molds, improves texture, and prevents unwanted contaminants |

| Types of Cheese | Commonly practiced with hard and semi-hard cheeses like Parmesan, Gruyère, and Cheddar |

| Aesthetic Impact | Creates a uniform, visually appealing rind |

| Historical Practice | Traditional method used for centuries in cheese making |

| Alternative Methods | Washing, bandaging, or waxing, depending on the desired cheese type |

| Hygiene | Helps remove surface impurities and excess moisture |

Explore related products

What You'll Learn

- Hygiene and Safety: Brushing removes mold, bacteria, and contaminants, ensuring cheese safety and preventing spoilage

- Aging Process Control: Brushing regulates moisture, texture, and flavor development during cheese maturation

- Mold Management: Controlled brushing encourages or removes specific molds for desired rind characteristics

- Aesthetic Appeal: Brushing creates a uniform, clean appearance, enhancing the cheese’s visual appeal

- Tradition and Craft: Brushing is a traditional technique preserving artisanal cheese-making methods and quality

Hygiene and Safety: Brushing removes mold, bacteria, and contaminants, ensuring cheese safety and preventing spoilage

Cheese wheels are brushed to maintain hygiene and safety, a critical step in the aging process that directly impacts the final product's quality and edibility. This practice is not merely cosmetic; it serves as a protective measure against the invisible threats of mold, bacteria, and contaminants that can compromise the cheese's integrity. The brushing process is a meticulous task, often done by skilled artisans who understand the delicate balance between allowing beneficial molds to flourish and preventing harmful microorganisms from taking hold.

In the world of cheese making, the surface of a wheel is a battleground where desirable and undesirable microorganisms compete. Brushing acts as a form of quality control, physically removing unwanted molds and bacteria that could lead to off-flavors, textures, or even health risks. For instance, certain molds can produce mycotoxins, harmful substances that may cause illness if consumed. By regularly brushing the cheese, typically every few days to weeks depending on the type and aging conditions, cheesemakers can significantly reduce the presence of these toxins. This process is particularly crucial for cheeses aged in natural rinds, where the environment is more conducive to microbial growth.

The technique and frequency of brushing vary widely depending on the cheese variety and aging method. For example, a semi-soft cheese like Reblochon might require more frequent brushing due to its higher moisture content, which can encourage bacterial growth. In contrast, a harder cheese such as Parmigiano-Reggiano may need less attention, as its lower moisture content naturally inhibits microbial activity. The tools used for brushing also differ; some cheesemakers prefer natural bristle brushes for their gentleness, while others use specialized tools designed to minimize damage to the rind.

From a practical standpoint, brushing is not just about removal but also about observation. Each brushing session provides an opportunity to inspect the cheese for any signs of abnormal growth or spoilage. This visual inspection is a critical part of the process, allowing cheesemakers to catch potential issues early. For home cheesemakers or those new to the craft, it’s essential to maintain a clean brushing environment and tools to avoid introducing new contaminants. Using a mild salt solution or food-grade sanitizers can aid in keeping brushes clean without affecting the cheese's flavor.

The benefits of brushing extend beyond immediate hygiene, contributing to the overall safety and longevity of the cheese. By maintaining a clean surface, cheesemakers can ensure that the aging process proceeds as intended, allowing the development of complex flavors and textures without the risk of spoilage. This practice is a testament to the blend of art and science in cheesemaking, where traditional methods meet modern safety standards. For consumers, the brushed cheese wheel is a symbol of care and craftsmanship, guaranteeing a product that is not only delicious but also safe to enjoy.

Who Moved My Cheese? Unraveling the Mystery of the Missing Cheese

You may want to see also

Aging Process Control: Brushing regulates moisture, texture, and flavor development during cheese maturation

Brushing cheese wheels during the aging process is a meticulous practice that serves as a cornerstone for controlling moisture, texture, and flavor development. This technique, often overlooked, is integral to the transformation of a raw cheese into a complex, mature product. By physically removing surface mold and excess moisture, brushing ensures that the cheese ages uniformly, preventing the formation of undesirable bacteria and maintaining the integrity of its rind. Without this intervention, the cheese could develop uneven textures or off-flavors, detracting from its final quality.

Consider the role of brushing in moisture regulation. As cheese matures, it naturally expels moisture, a process that concentrates flavors and firms the texture. Brushing accelerates this by removing surface moisture, allowing the cheese to dry more evenly. For example, in the production of Parmigiano-Reggiano, wheels are brushed weekly during the first year of aging. This consistent attention ensures that the cheese achieves its signature granular texture and deep, nutty flavor. Neglecting this step could result in a softer, less flavorful product, underscoring the importance of brushing in moisture control.

Texture development is another critical aspect influenced by brushing. The act of brushing not only removes mold but also massages the rind, promoting the breakdown of proteins and fats. This process contributes to the desired crumbly or creamy texture, depending on the cheese variety. For instance, aged Gouda benefits from regular brushing to develop its smooth, crystalline interior. Conversely, a lack of brushing can lead to a tough, rubbery rind that detracts from the eating experience. Thus, brushing is not merely cosmetic but a functional step in achieving the intended texture.

Flavor development is perhaps the most nuanced benefit of brushing. By controlling surface mold and moisture, brushing allows desirable microorganisms to flourish while inhibiting harmful ones. This balance fosters the creation of complex flavor profiles. Take Gruyère, for example, where brushing encourages the growth of specific molds that contribute to its earthy, slightly sweet taste. Without this intervention, the cheese might develop sharp or bitter notes, diminishing its appeal. Brushing, therefore, acts as a guardian of flavor, ensuring the cheese matures into its most exquisite form.

Practical implementation of brushing requires attention to timing and technique. For young cheeses (under 3 months), brushing should be done weekly to establish a clean rind. As the cheese ages, the frequency can be reduced to bi-weekly or monthly, depending on the desired outcome. Use a natural-bristle brush to avoid damaging the rind, and ensure the brushing area is clean to prevent contamination. For optimal results, pair brushing with proper humidity and temperature control, as these factors work in tandem to guide the aging process.

In conclusion, brushing cheese wheels is a vital yet understated practice in the art of cheese maturation. By regulating moisture, texture, and flavor, it ensures that each wheel reaches its full potential. Whether crafting a hard, aged cheese or a softer variety, mastering this technique is essential for any cheesemaker aiming to produce a superior product. Through careful, consistent brushing, the transformation from raw curd to culinary masterpiece becomes a controlled, predictable journey.

Is Hard Cheese Dairy? Understanding Its Classification and Nutritional Role

You may want to see also

Mold Management: Controlled brushing encourages or removes specific molds for desired rind characteristics

Cheese wheels are brushed as a deliberate act of mold management, a practice that transforms the rind from a mere barrier into a canvas for flavor and texture. This technique is not about eradication but curation, a delicate balance of encouraging beneficial molds while deterring undesirable ones. Imagine the rind as a garden where brushing acts as both weeding and watering, shaping the microbial ecosystem to achieve specific sensory outcomes. For instance, in the production of Gruyère, brushes remove excess moisture and unwanted molds, fostering the growth of *Brevibacterium linens*, which contributes to its distinctive earthy aroma and complex flavor profile.

The process begins with understanding the desired mold flora for each cheese variety. For example, soft-ripened cheeses like Brie thrive with *Penicillium camemberti*, while harder cheeses like Parmigiano-Reggiano benefit from *Penicillium candida*. Brushing frequency and pressure vary depending on the cheese’s age and moisture content. Young, moist cheeses may require daily brushing to prevent excessive mold growth, while older, drier cheeses might only need weekly attention. A soft-bristled brush is ideal for delicate rinds, whereas stiffer bristles are used for tougher surfaces. The goal is to create a uniform mold distribution without damaging the rind, ensuring consistent ripening.

Practical tips for effective mold management include monitoring humidity levels in the aging room, as excessive moisture can lead to uncontrolled mold growth. For example, maintaining humidity between 85-90% is optimal for most semi-hard cheeses. Additionally, brushing should be done in a sterile environment to avoid introducing contaminants. A solution of saltwater (2% salinity) can be used to clean brushes between uses, preventing cross-contamination. For aged cheeses like Cheddar, reducing brushing frequency as the rind dries helps preserve the natural mold balance, enhancing the cheese’s sharpness.

Comparatively, unbrushed cheeses often develop uneven rinds with unpredictable flavors, highlighting the importance of this controlled practice. For instance, unbrushed Camembert may develop bitter patches due to overgrowth of unwanted molds. In contrast, brushed Camembert exhibits a smooth, bloomy rind with a creamy interior and balanced flavor. This comparison underscores the precision required in brushing—it’s not a one-size-fits-all approach but a tailored technique that respects the unique characteristics of each cheese.

In conclusion, brushing cheese wheels is a nuanced art rooted in science, where the goal is to manipulate mold growth for desired rind characteristics. By understanding the specific needs of each cheese variety and employing precise techniques, cheesemakers can achieve consistent quality and flavor. Whether you’re a producer or an enthusiast, recognizing the role of brushing in mold management offers a deeper appreciation for the craftsmanship behind every wheel of cheese.

Is Cheese a Topping? Debunking the Pizza and Snack Debate

You may want to see also

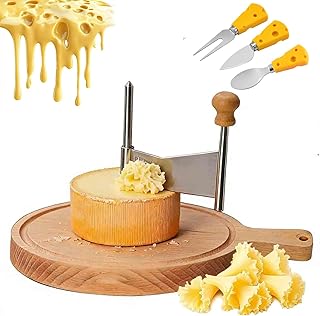

Explore related products

Aesthetic Appeal: Brushing creates a uniform, clean appearance, enhancing the cheese’s visual appeal

The surface of a cheese wheel is its canvas, and brushing is the artisan's stroke that transforms it from a rough, uneven exterior into a masterpiece of uniformity. This process is not merely about hygiene; it's an art form that elevates the cheese's visual allure, making it as pleasing to the eye as it is to the palate. Imagine a cheese board where each wheel boasts a smooth, consistent texture, free from blemishes and irregularities—a true testament to the craft.

The Art of Uniformity: Brushing cheese wheels is a meticulous task, requiring a gentle yet firm hand. The goal is to create a surface that appears untouched, as if the cheese naturally formed in this pristine state. This technique involves using specialized brushes with soft bristles, designed to caress the cheese without causing damage. The brushstrokes follow a specific pattern, often in circular motions, to ensure every inch is covered. For instance, a master cheesemaker might recommend 50 strokes per square inch, ensuring a flawless finish. This attention to detail is crucial, as it sets the foundation for the cheese's overall presentation.

Enhancing Visual Appeal: The aesthetic benefits of brushing are twofold. Firstly, it removes any surface imperfections, such as mold or discoloration, that could detract from the cheese's beauty. By doing so, the cheese's natural color and texture are revealed, allowing its unique characteristics to shine. For example, a brushed wheel of Cheddar will display its rich, golden hue, while a Brie will showcase its delicate, bloomy rind. Secondly, brushing creates a tactile experience, inviting consumers to appreciate the cheese's smoothness before even taking a bite. This sensory engagement is a powerful marketing tool, as it stimulates interest and desire.

Practical Tips for Cheesemakers: Achieving the perfect brushed finish requires practice and precision. Here's a step-by-step guide:

- Select the Right Brush: Choose a brush with natural bristles, as they are softer and less likely to scratch the cheese.

- Prepare the Cheese: Ensure the wheel is at room temperature to avoid cracking.

- Brush Technique: Start from the center and work outwards, using light pressure. For larger wheels, consider using a long-handled brush for better reach.

- Consistency is Key: Maintain a steady rhythm to achieve an even appearance.

- Final Touches: Inspect the wheel for any missed spots and gently brush them.

In the world of cheese, where presentation is paramount, brushing is an essential technique to master. It is the difference between a good cheese and a remarkable one, leaving a lasting impression on both connoisseurs and casual consumers alike. This simple yet effective method showcases the cheesemaker's dedication to craftsmanship, ensuring every wheel is a work of art.

Quarter Pounder with Cheese Meal: Ingredients, Calories, and Value Explained

You may want to see also

Tradition and Craft: Brushing is a traditional technique preserving artisanal cheese-making methods and quality

Brushing cheese wheels is a meticulous practice rooted in centuries-old artisanal traditions. Unlike mass-produced cheeses, which rely on mechanized processes, artisanal cheesemakers use brushing as a hands-on method to nurture the rind’s development. This technique involves gently sweeping the surface of the wheel with a natural bristle brush, often dipped in brine or water, to remove excess moisture and mold. By doing so, cheesemakers create an environment conducive to the growth of desirable bacteria and molds, which contribute to the cheese’s unique flavor, texture, and appearance. This labor-intensive step is a hallmark of craftsmanship, distinguishing artisanal cheeses from their factory-made counterparts.

The act of brushing is not merely functional but symbolic of a commitment to preserving heritage techniques. In regions like France, Italy, and Switzerland, where cheese-making is deeply intertwined with cultural identity, brushing is passed down through generations. For example, in the production of Gruyère, cheesemakers brush the wheels daily during the aging process, ensuring the rind remains supple and free of unwanted mold. This ritualistic care reflects a respect for tradition and an understanding that the smallest details—like the pressure applied during brushing or the frequency of the practice—can significantly impact the final product. It’s a testament to the belief that quality cannot be rushed or automated.

From a practical standpoint, brushing serves as a critical quality control measure. By regularly inspecting and cleaning the rind, cheesemakers can detect early signs of spoilage or uneven aging. For instance, brushing allows them to identify areas where harmful molds might be forming, enabling timely intervention. This proactive approach ensures consistency in the cheese’s quality, a key factor in maintaining the reputation of artisanal producers. It also fosters a deeper connection between the maker and the product, as each wheel is individually attended to, rather than being part of an anonymous production line.

To incorporate brushing into your own cheese-making practice, start by selecting the right tools. Natural bristle brushes, such as those made from boar hair, are ideal as they are gentle on the rind yet effective at removing debris. Brushes should be cleaned and sanitized between uses to prevent cross-contamination. For beginners, practice on smaller wheels and gradually increase the size as you gain confidence. Consistency is key—brush at regular intervals, typically every few days, depending on the cheese variety and aging conditions. Remember, brushing is as much an art as it is a science, requiring patience and attention to detail.

In an era dominated by industrialization, brushing cheese wheels stands as a defiant celebration of tradition and craft. It reminds us that true quality often lies in the hands of those who honor time-tested methods. By embracing this technique, both makers and consumers contribute to the preservation of a cultural legacy. Each brushed wheel tells a story of dedication, skill, and the enduring value of artisanal practices in a fast-paced world.

Unveiling the Mystery: Who Manufactured Chedobit Cheese Food?

You may want to see also

Frequently asked questions

Cheese wheels are brushed to remove excess moisture, mold, and bacteria from the rind, promoting even aging and preventing unwanted flavors or textures.

Brushing helps maintain a clean and controlled environment for the cheese to age properly, ensuring the rind develops correctly and the interior remains protected.

The frequency of brushing varies by cheese type, but it is typically done weekly or bi-weekly to manage mold growth and maintain the desired rind characteristics.

Yes, brushing influences flavor by controlling the type and amount of mold on the rind, which can contribute to the cheese's overall taste and aroma.

Natural bristle brushes or specialized tools are used to gently clean the rind without damaging the cheese or introducing contaminants.