The rate at which cheese molds can vary significantly depending on several factors, including moisture content, pH levels, salt concentration, and storage conditions. Cheeses with higher moisture content, such as fresh cheeses like mozzarella or ricotta, tend to mold faster because they provide a more hospitable environment for mold growth. Conversely, harder, drier cheeses like Parmesan or aged cheddar mold more slowly due to their lower moisture levels. Additionally, cheeses with lower pH levels or higher salt concentrations inhibit mold growth, as these conditions are less favorable for mold spores. Proper storage, such as refrigeration and airtight packaging, can also slow down mold development, highlighting the interplay between cheese composition and external factors in determining mold susceptibility.

| Characteristics | Values |

|---|---|

| Moisture Content | Higher moisture cheeses (e.g., fresh mozzarella, Brie) mold faster due to increased water activity, which supports microbial growth. |

| pH Level | Cheeses with higher pH (less acidic, e.g., fresh cheeses) are more prone to mold as molds thrive in less acidic environments. |

| Salt Content | Lower salt concentrations (e.g., in fresh cheeses) allow molds to grow more easily, as salt inhibits microbial activity. |

| Fat Content | Higher fat cheeses (e.g., cheddar) may mold less quickly due to fat's antimicrobial properties, though fat alone is not the primary factor. |

| Aging Time | Younger cheeses (e.g., ricotta) mold faster than aged cheeses (e.g., Parmesan), as aging reduces moisture and increases acidity. |

| Storage Conditions | Improper storage (e.g., high humidity, warm temperatures) accelerates mold growth regardless of cheese type. |

| Type of Rind | Soft-ripened cheeses (e.g., Camembert) with edible rinds mold faster due to surface exposure and specific mold cultures used in production. |

| Packaging | Poorly sealed or breathable packaging exposes cheese to mold spores, increasing the risk of mold growth. |

| Microbial Cultures | Cheeses with specific mold cultures (e.g., blue cheese) are intentionally molded but can still grow unwanted molds if conditions are unfavorable. |

| Exposure to Air | Cheeses exposed to air (e.g., sliced or improperly wrapped) are more susceptible to mold due to increased oxygen availability. |

Explore related products

What You'll Learn

- Moisture Content: Higher moisture cheeses mold faster due to favorable conditions for mold growth

- pH Levels: Cheeses with higher pH levels are more prone to mold development

- Salt Concentration: Lower salt content in cheese accelerates mold growth by reducing preservation

- Storage Conditions: Improper temperature and humidity speed up mold formation on cheese surfaces

- Type of Milk: Raw milk cheeses often mold faster than pasteurized due to bacteria presence

Moisture Content: Higher moisture cheeses mold faster due to favorable conditions for mold growth

Mold growth on cheese is a race against time, and moisture content is the starting pistol. Cheeses with higher moisture levels, like fresh mozzarella or ricotta, provide a more hospitable environment for mold spores to thrive. These cheeses, often containing 50-60% moisture, offer the perfect balance of water activity and nutrients that mold needs to grow. In contrast, harder cheeses like Parmesan or aged cheddar, with moisture levels around 30-40%, are less susceptible to mold due to their drier texture.

Consider the water activity (aw) of cheese, a measure of the availability of water for microbial growth. Molds typically require an aw above 0.85 to grow, and high-moisture cheeses often exceed this threshold. For instance, fresh chèvre, with an aw around 0.95, is highly prone to mold, whereas aged Gouda, with an aw around 0.80, is more resistant. To mitigate mold growth, store high-moisture cheeses in the refrigerator, where temperatures below 40°F (4°C) slow microbial activity, and wrap them in parchment paper to absorb excess moisture without suffocating the cheese.

From a practical standpoint, understanding moisture content can guide cheese storage and consumption. Soft, high-moisture cheeses like Brie or Camembert should be consumed within 7-10 days of opening, as their aw and nutrient profile make them prime targets for mold. Harder cheeses, such as Swiss or Pecorino, can last 3-4 weeks in the refrigerator due to their lower moisture content. For those who enjoy making cheese at home, controlling moisture during the aging process—by adjusting humidity levels or salting techniques—can significantly reduce mold risk.

The science behind moisture and mold is clear, but the art lies in balancing preservation with flavor. High-moisture cheeses often boast rich, creamy textures and complex flavors, making them worth the extra care. For example, wrapping these cheeses in waxed cheese paper allows them to breathe while minimizing moisture accumulation. Conversely, if mold does appear, it’s crucial to act swiftly: discard soft cheeses entirely if mold is present, but harder cheeses can often be salvaged by cutting away the moldy portion plus an additional 1 inch (2.5 cm) around it.

In essence, moisture content is a double-edged sword in the world of cheese. While it contributes to the sensory delights of soft, spreadable varieties, it also accelerates mold growth. By understanding this relationship, cheese enthusiasts can better preserve their favorites, ensuring each bite remains safe and satisfying. Whether you’re a casual consumer or a dedicated cheesemonger, mastering moisture management is key to prolonging the life of your cheese without compromising its quality.

Cheese's Unexpected Downfall: How It Troubled Jerome's Life

You may want to see also

pH Levels: Cheeses with higher pH levels are more prone to mold development

Cheese pH levels, typically ranging from 4.6 to 6.0, play a pivotal role in mold susceptibility. Cheeses like fresh mozzarella (pH 5.5–6.0) and cheddar (pH 5.2–5.5) sit on the higher end of this spectrum, making them more vulnerable to mold growth compared to acidic counterparts like feta (pH 4.6–4.8) or blue cheese (pH 4.8–5.2). This is because molds, such as *Penicillium* and *Mucor*, thrive in less acidic environments where pH exceeds 5.0. Understanding this pH-mold relationship allows cheesemakers to predict and manage spoilage risks effectively.

To illustrate, consider the aging process of cheddar. As it matures, its pH gradually rises due to the breakdown of lactose into lactic acid, which is then converted into milder compounds. This increase in pH creates a more hospitable environment for molds, necessitating careful humidity and temperature control during aging. Conversely, the brining process used in feta production keeps its pH low, inhibiting mold growth and extending shelf life. Monitoring pH during cheese production isn’t just a scientific exercise—it’s a practical tool for preserving quality and safety.

For home cheesemakers, controlling pH is both an art and a science. Adding specific cultures, such as *Lactococcus lactis*, during fermentation can lower pH levels, creating an environment less conducive to mold. For example, using a starter culture with a high acid-producing capacity can reduce the pH of a cheese to below 5.0 within 24 hours. Additionally, adjusting the salting process—applying 2–3% salt by weight—can further inhibit mold by drawing out moisture and lowering water activity. These steps, when combined, provide a robust defense against unwanted mold development.

However, it’s crucial to strike a balance. While lower pH levels deter mold, they can also impact flavor and texture. Overly acidic cheeses may become crumbly or develop sharp, unpleasant tastes. Cheesemakers must weigh the benefits of mold prevention against the sensory qualities consumers expect. For instance, a pH of 5.0 might be ideal for preventing mold in a semi-hard cheese, but pushing it to 4.8 could compromise its creamy mouthfeel. Precision in pH management is key to achieving both safety and palatability.

In practice, regular pH testing during cheese production is essential. Inexpensive pH meters or test strips can provide accurate readings, allowing adjustments to be made in real time. For aged cheeses, periodic monitoring during the aging process can catch pH shifts before they lead to mold issues. Pairing this with proper storage—maintaining temperatures below 50°F (10°C) and relative humidity around 85%—creates a multi-layered defense against mold. By mastering pH control, cheesemakers can ensure their products remain safe, flavorful, and mold-free.

Finding Velveeta Cheese at ShopRite: Aisle Location Guide

You may want to see also

Salt Concentration: Lower salt content in cheese accelerates mold growth by reducing preservation

Salt acts as a natural preservative in cheese, inhibiting the growth of unwanted microorganisms, including mold. When salt concentration is low, typically below 1.5% to 2% by weight, its antimicrobial properties weaken significantly. This threshold is critical because mold spores, ever-present in the environment, find a more hospitable environment in cheeses with reduced salt levels. For instance, fresh cheeses like mozzarella or ricotta, which often contain less than 1% salt, are more prone to molding within days if not stored properly. In contrast, harder cheeses like Parmesan, with salt concentrations around 3%, can resist mold growth for months.

The mechanism behind salt’s preservative effect lies in its ability to draw moisture out of microbial cells through osmosis, dehydrating them and halting their growth. Molds, being fungi, are particularly sensitive to this process. However, when salt levels are insufficient, molds can retain enough moisture to thrive. This is why artisanal or low-sodium cheeses often require stricter storage conditions, such as refrigeration below 4°C (39°F) and airtight packaging, to slow mold development. For home cheesemakers, monitoring salt dosage during production is crucial—aim for a minimum of 2% salt in fresh cheeses to strike a balance between flavor and preservation.

Consider the example of Brie versus cottage cheese. Brie, despite its soft texture, has a salt content around 2.5%, which, combined with its surface mold (a controlled Penicillium camemberti), prevents unwanted molds from taking hold. Cottage cheese, however, with its salt content often below 1%, molds rapidly if exposed to air. To extend its life, add a pinch of salt per cup of cottage cheese, though this may alter its taste slightly. This simple adjustment can buy an extra day or two before spoilage.

From a practical standpoint, understanding salt’s role allows consumers to make informed choices. For instance, if you prefer low-sodium cheeses, prioritize vacuum-sealed packaging and consume them within 3–5 days of opening. Alternatively, brine storage—immersing cheese in a saltwater solution (10% salt in water)—can preserve even low-salt varieties for weeks. However, this method alters texture and flavor, making it unsuitable for all types. Always label brined cheeses with the date to track freshness.

In summary, salt concentration is a pivotal factor in mold resistance, with lower levels creating an environment conducive to fungal growth. By adjusting storage methods or slightly increasing salt content, even delicate cheeses can be preserved longer. Whether you’re a cheesemaker or enthusiast, recognizing this relationship empowers you to minimize waste and maximize enjoyment. Remember: salt isn’t just seasoning—it’s a shield against spoilage.

Laughing Cow Cheese WW Points: A Complete Guide to Tracking

You may want to see also

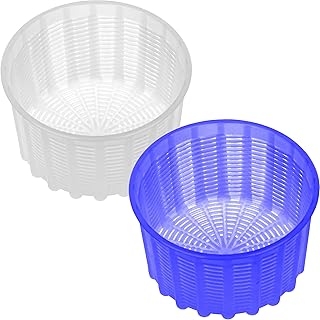

Explore related products

Storage Conditions: Improper temperature and humidity speed up mold formation on cheese surfaces

Mold growth on cheese is a race against time, and storage conditions are the starting pistol. Temperature and humidity, the dynamic duo of decay, can accelerate mold formation, turning a perfectly aged cheddar into a furry science experiment. The ideal storage temperature for most cheeses hovers between 35°F and 45°F (2°C and 7°C). Deviations from this range create a welcome mat for mold spores. Higher temperatures, say 50°F (10°C) and above, provide the warmth mold craves to thrive, while lower temperatures can slow its growth but may compromise texture and flavor.

Understanding the Size: How Big is a 1 Pound Block of Cheese?

You may want to see also

Type of Milk: Raw milk cheeses often mold faster than pasteurized due to bacteria presence

Raw milk cheeses often mold faster than their pasteurized counterparts, and the reason lies in the very essence of the milk itself. Raw milk, unlike pasteurized milk, retains its natural microbial population, including bacteria and fungi. These microorganisms are not inherently harmful; in fact, they contribute to the complex flavors and textures that make raw milk cheeses so prized among aficionados. However, this same microbial diversity creates an environment ripe for mold growth. When cheese is made from raw milk, the bacteria present can interact with the cheese’s surface, accelerating the conditions that molds thrive in, such as moisture and pH levels.

Consider the process of pasteurization, which heats milk to a specific temperature (typically 72°C for 15 seconds) to kill harmful pathogens and reduce microbial activity. This step significantly diminishes the number of bacteria in the milk, creating a less hospitable environment for mold. In contrast, raw milk cheeses are crafted without this heat treatment, preserving the full spectrum of microorganisms. While this can enhance flavor, it also means that raw milk cheeses are more susceptible to mold, particularly if stored improperly. For instance, a raw milk Camembert might develop mold within a week if left unwrapped in a humid environment, whereas a pasteurized version could remain mold-free for twice as long under the same conditions.

To mitigate mold growth in raw milk cheeses, proper storage is critical. Keep these cheeses in a cool, consistent environment, ideally at 4–8°C (39–46°F), and wrap them in breathable materials like wax or cheese paper to regulate moisture. Avoid plastic wrap, as it traps humidity and accelerates mold formation. If mold does appear, it’s not always cause for alarm. Hard raw milk cheeses, such as Gruyère, can often be salvaged by cutting away the moldy portion plus an additional 1 inch (2.5 cm) around it, as the denser texture prevents mold from penetrating deeply. However, soft raw milk cheeses like Brie should be discarded if mold appears, as the spores can spread quickly through their creamy interiors.

The choice between raw and pasteurized milk cheeses ultimately depends on your priorities: flavor complexity or shelf stability. Raw milk cheeses offer a depth of flavor that pasteurized versions often lack, but they require more attentive care. For those who appreciate the artisanal qualities of raw milk cheeses, understanding the role of bacteria in mold growth is key to enjoying them at their best. By embracing proper storage practices, you can savor the unique characteristics of raw milk cheeses while minimizing the risk of unwanted mold.

Cheese and Headaches: Uncovering the Hidden Triggers in Your Diet

You may want to see also

Frequently asked questions

Cheeses mold at different rates due to variations in moisture content, pH levels, salt concentration, and storage conditions. Softer, higher-moisture cheeses like Brie mold faster because mold thrives in damp environments, while harder, drier cheeses like Parmesan resist mold growth.

Yes, the type of milk (cow, goat, sheep) and its fat content can influence mold growth. Higher-fat cheeses may retain moisture longer, creating a favorable environment for mold, while lower-fat cheeses tend to dry out more quickly, slowing mold development.

Packaging plays a significant role in mold growth. Airtight, vacuum-sealed packaging slows mold by limiting oxygen exposure, while breathable wraps or exposed surfaces allow mold to develop faster due to increased air circulation and moisture retention.