Deli meat and cheese tend to spoil faster once sliced or cut due to increased exposure to air, moisture, and bacteria. When whole, the natural protective outer layer acts as a barrier against contaminants, but slicing disrupts this defense, creating more surface area for bacteria to grow. Additionally, deli meats often contain preservatives that are less effective once the meat is exposed to oxygen, accelerating spoilage. Proper storage, such as airtight packaging and refrigeration, can help slow this process, but the cut nature of these products inherently makes them more susceptible to rapid deterioration compared to their uncut counterparts.

| Characteristics | Values |

|---|---|

| Increased Surface Area | Cutting exposes more surface area to air, moisture, and microorganisms. |

| Loss of Protective Barrier | Slicing removes the outer layer (rind or casing) that protects against spoilage. |

| Moisture Loss | Sliced meat and cheese dry out faster due to increased exposure to air. |

| Microbial Growth | More exposed surfaces allow bacteria, mold, and yeast to grow more rapidly. |

| Oxidation | Sliced surfaces oxidize faster, leading to rancidity and off-flavors. |

| Temperature Fluctuations | Sliced products are more susceptible to temperature changes during storage. |

| Handling and Contamination | Increased handling during slicing and packaging can introduce pathogens. |

| Storage Conditions | Sliced products require more precise storage (e.g., airtight containers, refrigeration). |

| Preservative Efficacy | Preservatives in uncut products are more effective due to less exposure. |

| Texture and Quality Degradation | Sliced products lose texture and flavor faster due to moisture loss and oxidation. |

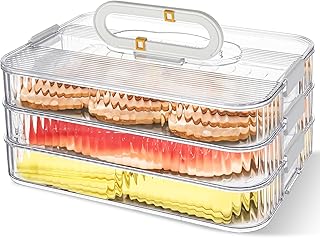

Explore related products

$11.72 $16.99

What You'll Learn

- Exposure to Air: Cutting increases surface area, allowing more air contact, speeding oxidation and bacterial growth

- Moisture Loss: Slicing disrupts natural barriers, causing faster moisture evaporation and drying

- Bacterial Entry: Cuts create entry points for bacteria, accelerating spoilage in meat and cheese

- Temperature Fluctuations: Sliced products are more sensitive to temperature changes, hastening degradation

- Packaging Inefficiency: Once opened, sliced items are harder to seal properly, reducing shelf life

Exposure to Air: Cutting increases surface area, allowing more air contact, speeding oxidation and bacterial growth

Cutting deli meat and cheese dramatically increases their exposure to air, a critical factor in their accelerated spoilage. When a block of cheese or a whole piece of meat is sliced, the newly exposed surfaces provide more entry points for oxygen. This oxygen fuels oxidation, a chemical reaction that breaks down fats and proteins, leading to off-flavors, discoloration, and a rancid smell. For example, sliced cheddar cheese can develop a sharp, unpleasant taste within days due to the oxidation of its milk fats, while an uncut block may remain fresh for weeks.

The increased surface area from cutting also creates a larger habitat for bacteria. While some bacteria are beneficial in cheese aging, most contribute to spoilage. Air carries microorganisms that land on the exposed surfaces, multiplying rapidly in the presence of moisture and nutrients. Deli meats, particularly those with higher fat content like salami, are especially vulnerable. A single slice of salami has more surface area than a whole sausage, allowing bacteria to thrive and produce toxins that cause foodborne illnesses.

To mitigate the effects of air exposure, consider practical storage strategies. Wrap sliced meats and cheeses tightly in plastic wrap or aluminum foil, pressing out as much air as possible. Alternatively, use vacuum-sealed bags to create an oxygen-free environment, which can extend shelf life by up to 50%. For those with access to specialized tools, a vacuum sealer is a worthwhile investment. Additionally, store deli items in the coldest part of the refrigerator, typically the bottom shelf, where temperatures are most consistent and below 40°F (4°C), slowing bacterial growth.

Comparing sliced and unsliced products highlights the impact of air exposure. A study found that pre-packaged sliced turkey spoils within 3–5 days, while a whole turkey breast can last up to 10 days when properly stored. Similarly, a block of Swiss cheese retains its quality for 3–4 weeks, whereas sliced Swiss begins to deteriorate after just 1–2 weeks. These examples underscore the importance of minimizing air contact to preserve freshness and safety.

Finally, for those who frequently consume deli meats and cheeses, adopting a "slice as needed" approach can significantly reduce waste. Purchase whole or larger portions and cut only what you plan to use immediately. This not only limits air exposure but also maintains the structural integrity of the product, preserving its texture and flavor. By understanding the role of air in spoilage, you can make informed choices to keep your deli items fresher for longer.

Are Old El Paso Nacho Cheese Taco Shells Discontinued? Find Out Now!

You may want to see also

Moisture Loss: Slicing disrupts natural barriers, causing faster moisture evaporation and drying

Slicing deli meat and cheese exposes more surface area to the air, accelerating moisture loss. This simple act of cutting disrupts the natural barriers that protect these foods, leaving them vulnerable to drying out. Imagine a whole block of cheddar versus thinly sliced pieces—the latter will shrink and harden far quicker due to evaporation. This phenomenon isn’t just about texture; moisture loss creates an environment where bacteria thrive, hastening spoilage.

To mitigate this, consider how you store sliced products. Wrap them tightly in plastic wrap or use airtight containers to minimize air exposure. For those who buy pre-sliced meats and cheeses, transfer them from their original packaging to vacuum-sealed bags if possible. A practical tip: lightly dampen a paper towel and place it in the container with the slices, ensuring it doesn’t directly touch the food. This adds just enough humidity to slow drying without promoting bacterial growth.

The science behind this is straightforward. When deli meat or cheese is uncut, its outer layer acts as a protective barrier, retaining moisture within. Slicing breaks this seal, allowing water molecules to escape more rapidly. For instance, a study found that sliced ham loses up to 30% more moisture within 48 hours compared to an uncut piece stored under the same conditions. This isn’t just a cosmetic issue—dryness alters flavor and texture, making the food less palatable and more susceptible to spoilage.

If you’re slicing at home, use a sharp knife to create clean cuts, minimizing damage to the food’s structure. However, even the most precise slicing will still increase moisture loss. For longevity, consider buying whole pieces and slicing only what you need. This approach not only preserves freshness but also reduces waste, as unsliced products generally last longer in the fridge. Remember, moisture loss is a silent culprit in food spoilage, and understanding its role empowers you to extend the life of your deli favorites.

Perfectly Crispy Goya Ham & Cheese Croquettes in Your Air Fryer

You may want to see also

Bacterial Entry: Cuts create entry points for bacteria, accelerating spoilage in meat and cheese

Cuts in deli meat and cheese act as open invitations for bacteria, significantly accelerating spoilage. When a knife slices through these foods, it creates microscopic pathways that breach their natural protective barriers. These barriers, such as the outer casing of cheese or the muscle fibers in meat, are designed to keep bacteria at bay. Once compromised, bacteria can infiltrate more easily, multiply rapidly, and break down the food’s structure, leading to off-putting odors, textures, and flavors. This process is why pre-sliced deli products often have shorter shelf lives than their uncut counterparts.

Consider the analogy of a fortress wall: intact, it keeps invaders out, but a single breach allows them to swarm in. Similarly, the surface of cheese or meat is relatively inhospitable to bacteria due to its low moisture and acidity levels. However, cuts expose the inner layers, which are richer in nutrients and moisture—ideal conditions for bacterial growth. For instance, *Listeria monocytogenes*, a common pathogen in deli meats, thrives in cool, moist environments and can colonize cut surfaces within hours. Even refrigeration, which slows bacterial activity, cannot completely halt this process once the barrier is broken.

Practical steps can mitigate this risk. First, store pre-sliced meats and cheeses in airtight containers or vacuum-sealed bags to minimize oxygen exposure, which bacteria need to grow. Second, consume sliced products within 3–5 days, compared to 1–2 weeks for uncut versions. If you buy whole blocks or logs, slice only what you’ll use immediately and leave the rest intact. For those who prefer pre-sliced convenience, look for products packaged with modified atmosphere (e.g., nitrogen or carbon dioxide), which inhibits bacterial growth. Lastly, maintain proper refrigerator temperatures (below 40°F or 4°C) to slow bacterial activity, though this alone won’t stop spoilage in cut items.

The takeaway is clear: cuts are not merely aesthetic changes but functional disruptions that fast-track spoilage. By understanding this mechanism, consumers can make informed choices to extend the life of their deli meats and cheeses. Whether slicing at home or purchasing pre-cut options, prioritizing storage practices and consumption timelines can reduce waste and ensure food safety. After all, the battle against bacteria begins with recognizing where they gain entry—and sealing those doors shut.

Cheesing the Demon Prince: Unlocking Secret Strategies for Easy Victory

You may want to see also

Explore related products

Temperature Fluctuations: Sliced products are more sensitive to temperature changes, hastening degradation

Sliced deli meats and cheeses are more vulnerable to temperature fluctuations than their uncut counterparts, and this sensitivity accelerates their spoilage. When a block of cheese or a whole piece of meat is sliced, the increased surface area exposes more of the product to the surrounding environment. This exposure is particularly problematic when temperatures vary, as it allows for faster moisture loss and microbial growth. For instance, a temperature shift from 4°C (39°F) to 10°C (50°F) for just a few hours can significantly increase the growth rate of bacteria like *Listeria monocytogenes*, which thrives in cooler environments. Such fluctuations are common in home refrigerators, where doors are frequently opened, or in deli cases where products are repeatedly exposed to room temperature during handling.

To mitigate this, maintaining a consistent temperature is crucial. The USDA recommends storing deli meats and cheeses at or below 4°C (40°F) to slow bacterial growth. However, even minor deviations can have a disproportionate impact on sliced products. For example, a study published in the *Journal of Food Protection* found that sliced turkey stored at 7°C (45°F) for 24 hours showed a 10-fold increase in bacterial counts compared to uncut turkey stored under the same conditions. This highlights the importance of not only setting your refrigerator to the correct temperature but also ensuring it maintains that temperature consistently. Investing in a refrigerator thermometer can help monitor fluctuations, especially in older appliances or those frequently opened.

Practical steps can further protect sliced products from temperature-related degradation. First, store deli meats and cheeses in airtight containers or vacuum-sealed bags to minimize exposure to air and temperature changes. Second, limit the time sliced products spend outside refrigeration. For example, when preparing sandwiches, assemble them just before consumption rather than hours in advance. Third, consider purchasing smaller quantities of sliced products more frequently to reduce the duration they are exposed to varying temperatures. For households, buying a quarter-pound of sliced ham instead of a half-pound can make a difference, as smaller portions are consumed faster and spend less time in the refrigerator.

Comparatively, uncut products have a natural barrier—their outer layer—that protects the interior from rapid temperature changes and microbial invasion. Slicing disrupts this barrier, making sliced products inherently more susceptible. Think of it like cutting into an apple: the exposed flesh browns quickly due to oxidation, while the uncut portion remains intact. Similarly, sliced deli meats and cheeses oxidize faster and lose moisture more readily, especially when temperatures fluctuate. This process not only affects texture and flavor but also creates an environment conducive to spoilage. By understanding this mechanism, consumers can adopt storage practices that prioritize temperature stability, such as placing sliced products in the coldest part of the refrigerator (usually the back) and avoiding overloading the fridge, which can block airflow and cause uneven cooling.

In conclusion, temperature fluctuations pose a unique threat to sliced deli meats and cheeses, hastening their degradation through increased surface exposure and microbial activity. By maintaining consistent refrigeration, using proper storage methods, and minimizing exposure to room temperature, consumers can significantly extend the shelf life of these products. While uncut items have natural protections against temperature changes, sliced products require proactive measures to counteract their heightened vulnerability. Adopting these practices not only reduces food waste but also ensures safer consumption by minimizing the risk of foodborne illnesses.

Cheese and Sprinkles: Decoding the Meaning Behind the Quirky Expression

You may want to see also

Packaging Inefficiency: Once opened, sliced items are harder to seal properly, reducing shelf life

Sliced deli meats and cheeses face a critical vulnerability once their original packaging is breached: the inability to recreate an airtight seal. Unlike whole, uncut products, which benefit from a natural barrier against oxygen and moisture, sliced items rely entirely on their packaging for protection. When a package is opened, the integrity of this barrier is compromised, and resealing it with plastic wrap or a clip rarely restores the original level of protection. This exposure accelerates spoilage by allowing oxygen to oxidize fats, moisture to promote bacterial growth, and external contaminants to infiltrate.

Consider the mechanics of resealing. Plastic wrap, while convenient, often leaves microscopic gaps that permit air exchange. Even vacuum-sealed containers, if not used correctly, can lose their effectiveness after repeated openings. For instance, a study found that deli meats stored in improperly sealed containers spoiled 40% faster than those in factory-sealed packaging. This highlights the importance of using tools like vacuum sealers or specialized deli containers, which can significantly extend shelf life by minimizing oxygen exposure. However, these solutions are not always practical for everyday consumers, leaving many to rely on suboptimal resealing methods.

The consequences of inadequate sealing are particularly pronounced in sliced products due to their increased surface area. Each slice exposes more of the product to air, multiplying the risk of oxidation and microbial growth. For example, a single slice of cheddar cheese has roughly 50% more exposed surface area than an equivalent weight of uncut cheese. When combined with poor sealing, this makes sliced cheese spoil up to twice as fast as its uncut counterpart. Similarly, deli meats like turkey or ham, which contain higher fat content, are especially susceptible to rancidity when exposed to oxygen, further emphasizing the need for effective resealing.

To mitigate these issues, consumers can adopt practical strategies. First, portion control is key: purchase smaller quantities of sliced items to reduce the number of times a package is opened. Second, invest in quality storage solutions, such as beeswax wraps or silicone storage bags, which provide a more effective seal than traditional plastic wrap. Third, store sliced products at the correct temperature—below 40°F (4°C)—to slow bacterial growth. Finally, consider freezing portions that won’t be consumed within a few days; properly wrapped, deli meats and cheeses can last up to 2 months in the freezer without significant quality loss. By addressing packaging inefficiency through these measures, consumers can significantly prolong the freshness of sliced items.

Brie Without Chill: Consequences of Unrefrigerated Cheese Storage

You may want to see also

Frequently asked questions

Deli meat and cheese spoil faster after being sliced because cutting them increases their surface area, exposing more of the food to bacteria, oxygen, and moisture, which accelerate spoilage.

Slicing disrupts the protective outer layer of deli meat and cheese, allowing bacteria to penetrate more easily. Additionally, sliced products are often stored in conditions that promote bacterial growth, such as refrigeration temperatures that are not cold enough.

Yes, proper storage can slow down spoilage. Wrapping sliced products tightly in plastic wrap or storing them in airtight containers reduces exposure to air and moisture. Keeping them at the correct refrigerator temperature (below 40°F or 4°C) also helps extend their shelf life.