The question of why cheese is often square or circular, rather than any other shape, is rooted in practicality and tradition. Square cheese blocks are common because they maximize efficiency in production and packaging, fitting neatly into containers and reducing waste. Circular cheese, on the other hand, is typically associated with wheels, a shape that has historical significance dating back to when cheese was manually pressed and aged. This shape allowed for easier handling, rolling, and storage in cellars or caves. Ultimately, the shape of cheese is influenced by a combination of manufacturing processes, cultural preferences, and functional considerations, making square and circular forms the most prevalent in the cheese industry.

| Characteristics | Values |

|---|---|

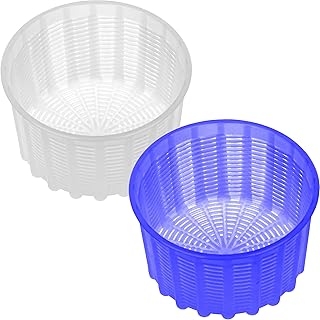

| Shape of Cheese | Cheese is typically produced in circular shapes due to the traditional cheese-making process, where curds are pressed in round molds. |

| Packaging and Storage | Square or rectangular shapes are more efficient for packaging, stacking, and transportation, reducing waste and maximizing storage space. |

| Consumer Preferences | Some consumers prefer square or rectangular cheese for ease of slicing, portion control, and fitting into sandwiches or toast. |

| Industrial Production | Modern cheese production often uses rectangular or square molds for mass production, as they are easier to automate and handle. |

| Historical Reasons | Traditional cheese-making methods favored round shapes, but industrial advancements led to the adoption of more practical, space-efficient shapes. |

| Marketing and Branding | Cheese manufacturers may choose square or rectangular shapes for branding purposes, as they can be more visually appealing on packaging. |

| Cultural Variations | Different cultures have varying preferences for cheese shapes, with some favoring rounds and others preferring squares or rectangles. |

| Cost Efficiency | Square or rectangular cheese blocks can reduce production costs by minimizing material waste and optimizing cutting processes. |

| Retail Display | Square or rectangular cheese is often easier to display on retail shelves, providing a neat and organized appearance. |

| Technological Advancements | Advances in cheese-making technology have made it easier to produce cheese in various shapes, including squares and rectangles, without compromising quality. |

Explore related products

What You'll Learn

- Historical Cheese Molds: Early cheese molds were often circular or square, shaping cheese for practical reasons

- Modern Production Efficiency: Square blocks maximize space in packaging and transportation, reducing waste and costs

- Consumer Perception: Circular cheese is often seen as artisanal, while square is associated with convenience

- Cultural Influences: Regional traditions dictate shape; some cultures prefer rounds, others rectangles or squares

- Technological Limitations: Machinery for mass production favors straight edges, making squares easier to manufacture

Historical Cheese Molds: Early cheese molds were often circular or square, shaping cheese for practical reasons

The shape of cheese has long been influenced by the molds used in its production, with early cheese molds favoring circular or square designs for practical reasons. These shapes were not arbitrary but rather a result of the materials and techniques available at the time. Wooden molds, for instance, were easily crafted into simple geometric forms, making circles and squares the most efficient and durable options. This practicality extended to storage and transportation, as square cheeses could be packed tightly without wasting space, while circular molds allowed for even pressure distribution during pressing, essential for proper curd consolidation.

Consider the process of cheese making in medieval Europe, where cheese molds were often carved from wood or fashioned from wicker. A circular mold, with its even curvature, facilitated the drainage of whey and ensured uniform moisture distribution. This was particularly important for softer cheeses, where consistency in texture was critical. Square molds, on the other hand, were favored for harder cheeses, as their straight edges provided stability during the lengthy aging process. For example, a 10-inch square mold could hold approximately 5 liters of curd, making it ideal for producing a standard-sized wheel of cheddar or Gouda.

From a comparative perspective, the choice between circular and square molds also reflected regional preferences and available resources. In areas with abundant timber, wooden molds dominated, while regions with access to reeds or willow branches often employed wicker molds, which were lighter and more flexible. The durability of wooden molds made them suitable for repeated use, but they required regular maintenance to prevent cracking or warping. Wicker molds, though less durable, were easier to replace and allowed for more intricate patterns, such as braided edges, which added aesthetic value to the final product.

To replicate historical cheese molding techniques, start by selecting the appropriate material for your mold. For a circular wooden mold, use a hardwood like maple or beech, ensuring it is food-safe and free from splinters. Cut a disc approximately 12 inches in diameter and 2 inches deep, then sand the edges smooth. For a square mold, construct a box from 1-inch thick wooden slats, ensuring the corners are tightly joined. Line both types of molds with cheesecloth to prevent sticking and aid in whey drainage. When pressing the curds, apply even pressure—a weight of 10-15 pounds for softer cheeses and up to 50 pounds for harder varieties—and monitor the process to achieve the desired density.

In conclusion, the historical use of circular and square cheese molds was driven by practicality, resource availability, and the specific requirements of different cheese types. By understanding these factors, modern cheese makers can appreciate the ingenuity of their predecessors and even experiment with traditional techniques. Whether crafting a rustic farmhouse cheese or a meticulously aged wheel, the shape of the mold remains a testament to the balance between function and tradition in the art of cheese making.

Cheese Hats at RNC: Unraveling the Quirky Political Fashion Statement

You may want to see also

Modern Production Efficiency: Square blocks maximize space in packaging and transportation, reducing waste and costs

Cheese blocks are often square because geometry favors efficiency. Squares and rectangles tessellate perfectly, leaving no gaps when packed together. This principle, borrowed from ancient tiling techniques, minimizes wasted space in packaging and shipping containers. For instance, a standard 40-pound block of cheddar, measuring 12 inches by 12 inches by 4 inches, fits snugly into a pallet configuration with no voids, allowing for up to 20% more product per shipment compared to circular shapes.

Consider the logistics: a truckload of square cheese blocks can carry approximately 1,800 units, while the same space would accommodate only 1,500 circular blocks of equivalent volume. This difference translates to fewer trips, lower fuel consumption, and reduced carbon emissions. Manufacturers save on transportation costs, and retailers benefit from optimized shelf space. For small businesses, this efficiency can mean the difference between profit and loss, especially when scaling production.

However, achieving this efficiency requires precision in production. Cheese blocks must be cut with tolerances of less than 1 millimeter to ensure perfect alignment. Modern cutting machines, like the Tetra Pak® Cube Filler, use laser-guided blades to achieve this accuracy. Pairing these blocks with vacuum-sealed packaging further reduces waste, as the material conforms tightly to the square shape. For home users, storing square cheese in airtight containers with parchment paper between layers prevents moisture loss and extends shelf life by up to 30%.

Critics argue that circular cheese wheels have historical and artisanal value, but the data is clear: square blocks outperform in modern supply chains. A 2022 study by the Dairy Research Institute found that transitioning to square packaging reduced industry-wide packaging waste by 15% annually. While tradition has its place, the economic and environmental benefits of square cheese blocks are undeniable. For businesses and consumers alike, embracing this shape is a practical step toward sustainability and cost-effectiveness.

Parmesan Cheese and Penicillium: Unraveling the Moldy Truth

You may want to see also

Consumer Perception: Circular cheese is often seen as artisanal, while square is associated with convenience

Cheese shape isn't arbitrary. The circle and the square carry unspoken messages, influencing consumer perception before a single bite is taken. Circular cheese, with its organic curves and lack of sharp edges, evokes a sense of tradition and craftsmanship. Think of a wheel of aged cheddar, its rind slightly wrinkled, hinting at a slow, meticulous aging process. This shape suggests a product made in smaller batches, by hand, with attention to detail – the hallmarks of artisanal production.

Consumers, increasingly drawn to the story behind their food, are more likely to perceive circular cheese as a premium, specialty item, worth a higher price point.

Square cheese, on the other hand, screams efficiency. Its straight edges and uniform shape are a testament to industrialization. Imagine a neatly stacked display of individually wrapped cheese slices, perfectly sized for sandwiches or quick snacks. This shape lends itself to mass production, easy packaging, and convenient consumption. It's the cheese of practicality, readily available and affordable, catering to the needs of busy individuals and families.

While lacking the romantic allure of its circular counterpart, square cheese dominates the market due to its accessibility and versatility.

This perception gap isn't just about aesthetics. It's rooted in the historical production methods of cheese. Traditional cheesemaking often involved using round molds, allowing the cheese to drain and form naturally. Square shapes, however, became prevalent with the advent of mechanized production, where efficiency and standardization were paramount. This historical context has subtly shaped our subconscious associations, linking circular cheese to a bygone era of artisanal craftsmanship and square cheese to the conveniences of modern life.

Understanding these perceptions allows marketers and cheesemakers to strategically leverage shape. Artisanal producers can emphasize the traditional, handcrafted nature of their circular cheeses, appealing to consumers seeking a unique, premium experience. Conversely, brands targeting convenience-oriented consumers can highlight the practicality and affordability of their square offerings. By playing into these established associations, they can effectively communicate the value proposition of their products without uttering a word about shape.

Jello Cheesecake Mix: Additional Ingredients Needed or Ready-to-Use?

You may want to see also

Explore related products

Cultural Influences: Regional traditions dictate shape; some cultures prefer rounds, others rectangles or squares

Cheese shapes are not arbitrary; they are deeply rooted in cultural traditions that reflect history, practicality, and regional identity. In France, for example, the round Camembert is a symbol of Norman craftsmanship, its shape derived from the wooden molds used by local farmers. Similarly, Italy’s rectangular Parmigiano-Reggiano reflects the need for efficient stacking and aging in large warehouses. These shapes are more than aesthetic choices—they are functional designs honed over centuries to suit local production methods and storage needs.

Consider the cultural preferences that drive these shapes. In the Middle East, circular cheeses like Akkawi are common, often tied to communal eating practices where the cheese is easily divided and shared. In contrast, the Netherlands favors rectangular Gouda, a shape that aligns with their tradition of slicing and packaging for export. These regional preferences are not just about tradition; they influence how cheese is consumed, stored, and perceived globally. For instance, a round cheese might evoke rustic charm, while a square one suggests precision and modernity.

To understand these traditions, examine the tools and techniques passed down through generations. In Switzerland, the square shape of Appenzeller cheese is tied to the wooden presses used in alpine dairies, which imprint a distinctive pattern on its rind. In contrast, British cheeses like Cheddar are often rectangular, a legacy of the large blocks historically cut into smaller portions for sale. These methods are not merely historical footnotes—they continue to shape modern production, even as technology advances.

Practicality also plays a role. Round cheeses, like Spain’s Manchego, are often aged in smaller formats, ideal for household consumption. Rectangular or square cheeses, such as American Cheddar, are designed for easy slicing and packaging in supermarkets. For home cheesemakers, understanding these traditions can guide mold selection: use round molds for soft cheeses meant for sharing, and rectangular ones for hard cheeses intended for long-term storage.

Ultimately, the shape of cheese is a cultural artifact, telling stories of regional identity, practicality, and tradition. Whether you’re a producer or a consumer, recognizing these influences adds depth to your appreciation of cheese. Next time you slice into a wheel or block, consider the centuries of craftsmanship and culture that shaped it—literally.

Is Cheese Acidic or Neutral? Unraveling the pH Mystery

You may want to see also

Technological Limitations: Machinery for mass production favors straight edges, making squares easier to manufacture

The geometry of cheese is not arbitrary. Modern cheese production relies heavily on machinery designed for efficiency and scalability. These machines, from cutting wires to packaging lines, are engineered to handle straight edges with precision. A square block of cheese, for instance, can be cut, stacked, and wrapped with minimal waste and maximum speed. Curved shapes, like circles, introduce complexities: uneven edges complicate stacking, increase material waste, and slow down automated processes. This isn’t just about aesthetics—it’s about optimizing production for a global market that demands consistency and affordability.

Consider the cutting process. High-speed cheese cutters use straight wires or blades to slice through large blocks. These tools are calibrated for linear movement, ensuring clean, uniform cuts. A circular shape would require a rotating blade or a more intricate cutting mechanism, both of which are slower and more prone to error. For example, a 40-pound block of cheddar can be divided into 100 square slices in under a minute using linear cutting technology. Attempting the same with circular slices would reduce output by up to 30%, as the blade would need to adjust its path for each curved edge.

Packaging further highlights the advantage of squares. Automated packaging machines are designed to handle rectangular objects. A square block of cheese fits seamlessly into a standard carton or shrink wrap, with minimal adjustments needed for the machine. Circular cheeses, however, require custom packaging solutions, such as round containers or additional material to account for the uneven shape. This not only increases costs but also slows down the line. For instance, a packaging machine can process 200 square cheese blocks per minute, compared to 120 circular ones, due to the extra time needed to align and seal curved edges.

Even distribution channels favor square cheese. Retailers prefer products that maximize shelf space and minimize handling complexity. A square block stacks neatly, reducing the risk of toppling displays and making inventory management simpler. Circular cheeses, while visually appealing, often require specialized shelving or additional labor to arrange properly. For small businesses, this might mean the difference between a profitable display and one that requires constant maintenance. A study by the Food Packaging Forum found that square-packaged products are 25% more likely to be restocked efficiently compared to their circular counterparts.

In conclusion, the dominance of square cheese is a direct result of technological constraints in mass production. From cutting to packaging to retail, every step of the process is optimized for straight edges. While circular cheese has its charm, the efficiency gains of squares—faster production, lower costs, and easier handling—make them the practical choice for manufacturers and consumers alike. This isn’t a limitation of creativity but a testament to how technology shapes even the most mundane aspects of our lives, like the shape of our food.

Revive Your Cheese Curds: Simple Tips to Restore Freshness and Squeak

You may want to see also

Frequently asked questions

Cheese is typically produced in square or circular shapes due to the molds and presses used during the cheese-making process. These shapes are practical for manufacturing, packaging, and storage.

The shape of cheese often depends on tradition, regional preferences, and the type of cheese being made. For example, cheddar is commonly rectangular or square, while brie is traditionally round.

No, cheese does not naturally form into square or circular shapes. These shapes are the result of human-made molds, presses, or cutting techniques used during production.