Good cheese often comes with a hefty price tag due to the intricate and time-consuming process involved in its production. Crafting high-quality cheese requires premium ingredients, such as fresh, high-grade milk, often sourced from specific breeds of animals raised in optimal conditions. Additionally, traditional methods, including aging and fermentation, can take weeks, months, or even years, during which the cheese must be carefully monitored and maintained in controlled environments. Skilled artisans and cheesemakers play a crucial role, as their expertise ensures the cheese develops the desired flavor, texture, and complexity. These factors, combined with the costs of labor, equipment, and compliance with food safety regulations, contribute to the elevated price of good cheese, making it a luxury item for many consumers.

| Characteristics | Values |

|---|---|

| Aging Time | Many high-quality cheeses require months or even years to age properly, during which time they lose moisture and develop complex flavors. This extended aging process increases costs. |

| Milk Quality | Premium cheeses often use high-quality milk from grass-fed or pasture-raised animals, which is more expensive than standard milk due to higher animal welfare and feed costs. |

| Artisanal Production | Small-batch, handcrafted cheeses are labor-intensive and require skilled cheesemakers, driving up production costs compared to mass-produced varieties. |

| Specialized Ingredients | Some cheeses include expensive ingredients like truffles, herbs, or specific molds, adding to the overall cost. |

| Low Yield | The cheese-making process results in a significant loss of milk volume, as it takes about 10 pounds of milk to make 1 pound of cheese, increasing the cost per unit. |

| Regulations and Standards | Many premium cheeses must adhere to strict regional or traditional production methods (e.g., PDO or AOC certifications), which can be costly to maintain. |

| Distribution and Storage | High-quality cheeses often require specialized storage (e.g., temperature-controlled environments) and careful handling during distribution, adding to expenses. |

| Demand and Scarcity | Limited production and high demand for certain artisanal or rare cheeses drive up prices due to market dynamics. |

| Health and Safety Standards | Maintaining high hygiene and safety standards in cheese production facilities increases operational costs. |

| Brand Reputation | Established brands or renowned cheesemakers can command higher prices due to their reputation for quality and consistency. |

Explore related products

What You'll Learn

- Aging Process: Longer aging increases flavor complexity and reduces yield, raising costs significantly

- Quality Ingredients: Premium milk from grass-fed animals or specific breeds adds to expense

- Artisanal Craftsmanship: Handmade techniques require skilled labor and time-intensive methods

- Small Batch Production: Limited quantities mean higher overhead per unit produced

- Regulations & Standards: Strict certifications and import tariffs inflate prices

Aging Process: Longer aging increases flavor complexity and reduces yield, raising costs significantly

The aging process is a critical factor in determining the cost of high-quality cheese. When cheese is aged, it undergoes a series of biochemical transformations that enhance its flavor, texture, and overall complexity. However, this process is time-consuming and requires precise conditions, such as controlled temperature and humidity, to ensure the cheese develops optimally. Longer aging periods allow for the breakdown of proteins and fats, creating a more intense and nuanced flavor profile. For example, a cheese aged for 12 months will have a deeper, more complex taste compared to one aged for only 3 months. This extended aging not only demands more time but also necessitates careful monitoring and maintenance of the aging environment, adding to the overall production costs.

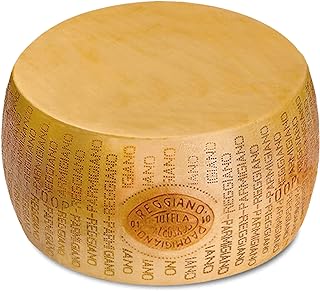

As cheese ages, it naturally loses moisture through evaporation, a process known as syneresis. This moisture loss concentrates the flavors but also reduces the final yield. For instance, a wheel of cheese might start at 10 pounds before aging but shrink to 7 or 8 pounds after several months. This reduction in yield means that producers have less product to sell, even though the production costs remain the same or increase due to the extended aging time. The economic principle of supply and demand comes into play here: with less cheese available after longer aging, the price per unit must rise to cover the expenses and maintain profitability. This is why longer-aged cheeses, such as aged Goudas or Parmigiano-Reggiano, are significantly more expensive than their younger counterparts.

The aging process also involves a higher risk of loss due to spoilage or imperfections. Even under ideal conditions, some wheels of cheese may develop mold, cracks, or other defects that render them unsellable. These losses are more likely to occur during longer aging periods, as the cheese is exposed to potential issues for an extended duration. Producers must account for this risk in their pricing, further driving up the cost of longer-aged cheeses. Additionally, the expertise required to manage the aging process is specialized and often comes at a premium. Skilled affineurs (cheese aging experts) play a crucial role in ensuring the cheese develops correctly, and their knowledge and labor contribute to the higher cost of the final product.

Another aspect of the aging process that impacts cost is the need for dedicated storage space. Aging cheese requires large, climate-controlled facilities that can maintain specific conditions for months or even years. These facilities are expensive to build, maintain, and operate, with costs including energy for refrigeration, humidity control systems, and regular cleaning to prevent contamination. The longer the cheese ages, the more it ties up valuable storage space that could otherwise be used for other products. This opportunity cost, combined with the operational expenses of the aging facility, is factored into the price of the cheese. As a result, consumers pay a premium for the privilege of enjoying a cheese that has been carefully aged to perfection.

Finally, the market demand for longer-aged cheeses plays a role in their higher price point. Consumers who seek out these cheeses are often willing to pay more for the superior quality and unique flavor profiles they offer. This willingness to pay a premium allows producers to recoup their higher production costs and invest in the labor-intensive, time-consuming aging process. However, it also means that longer-aged cheeses remain a luxury item, accessible primarily to those who can afford the elevated price tag. In essence, the cost of good cheese reflects not just the ingredients and initial production but also the artistry, patience, and resources required to transform it into a truly exceptional product through extended aging.

Discover Tasty Alternatives to Blue Cheese for Your Next Recipe

You may want to see also

Quality Ingredients: Premium milk from grass-fed animals or specific breeds adds to expense

The cost of producing high-quality cheese begins with the source of its primary ingredient: milk. Premium cheese often relies on milk from grass-fed animals, which inherently increases production costs. Grass-fed cows, goats, or sheep require access to expansive pastures and a diet rich in fresh, natural forage. Maintaining these pastures involves significant expenses, including land management, fencing, and ensuring the soil remains nutrient-dense to support healthy grass growth. Unlike grain-fed animals, grass-fed livestock take longer to reach optimal milk production, further adding to the time and resources invested. This slower, more natural process results in milk that is richer in flavor and nutrients but comes at a higher cost to the producer.

The breed of the animal also plays a critical role in the quality and expense of the milk used for cheese. Specific breeds, such as Jersey or Brown Swiss cows, are prized for their milk’s high butterfat content and unique flavor profiles. These breeds, however, often produce less milk volume compared to more common dairy breeds like Holsteins. Raising these specialized breeds requires careful breeding programs, health management, and tailored nutrition, all of which contribute to higher operational costs. Additionally, the milk from these breeds is often in limited supply, driving up its market price. Cheese makers who choose such premium milk are therefore paying a premium themselves, a cost that is ultimately reflected in the final product.

Grass-fed milk also tends to have a more complex and desirable flavor profile, which is essential for crafting artisanal cheeses. The natural diet of the animals imparts subtle nuances to the milk, such as nutty, earthy, or floral notes, depending on the type of grass and forage consumed. This flavor complexity is highly sought after by cheese makers and consumers alike but requires meticulous care in animal husbandry. For instance, farmers must rotate grazing areas to ensure the animals always have access to fresh, high-quality forage, which is labor-intensive and costly. These practices, while beneficial for the quality of the milk, add layers of expense that are passed on to the consumer.

Furthermore, the use of milk from grass-fed or specific breeds often aligns with sustainable and ethical farming practices, which are increasingly valued by consumers. Such practices may include organic certification, humane treatment of animals, and reduced environmental impact. Achieving these standards requires adherence to strict regulations and additional investments in infrastructure and training. For example, organic certification involves avoiding synthetic pesticides and fertilizers, which can increase the cost of maintaining pastures. While these practices contribute to the overall quality and ethical appeal of the cheese, they also significantly raise production costs, making the final product more expensive.

In summary, the use of premium milk from grass-fed animals or specific breeds is a major factor in the high cost of good cheese. The expenses associated with maintaining pastures, raising specialized breeds, and adhering to sustainable practices all contribute to the price tag. However, these investments result in milk with superior flavor, nutritional value, and ethical credentials, which are essential for producing exceptional cheese. For consumers who value quality and craftsmanship, understanding these costs highlights why premium cheese is worth its price.

Swiss Cheese and Keto: A Perfect Low-Carb Diet Match?

You may want to see also

Artisanal Craftsmanship: Handmade techniques require skilled labor and time-intensive methods

Artisanal craftsmanship lies at the heart of why good cheese commands a premium price. Unlike mass-produced cheeses, which rely on automated processes and standardized recipes, artisanal cheeses are crafted by skilled cheesemakers who bring years of experience and a deep understanding of their craft. These artisans often work in small batches, meticulously overseeing every step of the cheesemaking process, from curdling the milk to aging the final product. This hands-on approach ensures a level of quality and consistency that machines simply cannot replicate. However, such expertise comes at a cost, as skilled labor is both rare and highly valued in the industry.

The time-intensive nature of handmade techniques further contributes to the expense of artisanal cheese. Traditional methods, such as hand-cutting curds, stirring vats of milk by hand, and manually flipping and brushing cheeses during aging, require hours—sometimes even days—of dedicated work. For example, a single wheel of aged cheddar or Gruyère may take months or even years to mature to perfection, during which time it must be carefully monitored and tended to. This slow, deliberate process stands in stark contrast to the rapid production cycles of industrial cheese factories, where efficiency is prioritized over craftsmanship. The extended production timeline ties up resources and labor, adding to the overall cost of the final product.

Another factor tied to artisanal craftsmanship is the use of high-quality, often locally sourced ingredients. Artisan cheesemakers frequently work with milk from pasture-raised animals, which can be more expensive due to the higher welfare standards and sustainable farming practices involved. Additionally, they may use traditional cultures and rennet, which, while contributing to the unique flavor and texture of the cheese, are pricier than their synthetic counterparts. These choices reflect a commitment to quality and authenticity, but they also drive up production costs, which are ultimately passed on to the consumer.

The artistry involved in crafting artisanal cheese also extends to the aging process, a stage that demands both skill and patience. Cheesemakers must create the ideal environment for their cheeses to develop complex flavors and textures, often experimenting with temperature, humidity, and even microbial cultures. This trial-and-error process can be unpredictable, and not every batch turns out perfectly, leading to potential losses. Moreover, the space required to age cheeses—climate-controlled cellars or caves—is expensive to maintain. These additional expenses, combined with the labor-intensive nature of the work, make artisanal cheese a luxury item rather than an everyday staple.

Finally, the scale of production plays a significant role in the cost of artisanal cheese. Small-batch cheesemakers lack the economies of scale enjoyed by large industrial producers, meaning they cannot spread their fixed costs—such as equipment, facilities, and labor—across a vast quantity of product. As a result, each wheel or block of artisanal cheese bears a larger share of these expenses. Consumers who purchase artisanal cheese are not just buying a food product; they are investing in a tradition, a craft, and a commitment to quality that cannot be rushed or replicated on a mass scale. This exclusivity and attention to detail are what make artisanal cheese so special—and so expensive.

Cheese Steaks: How Long Do They Stay Fresh?

You may want to see also

Explore related products

Small Batch Production: Limited quantities mean higher overhead per unit produced

Good cheese often comes with a higher price tag, and one of the primary reasons is the small batch production process. Unlike mass-produced cheeses, artisanal or high-quality cheeses are typically made in limited quantities. This approach ensures meticulous attention to detail and quality but also results in higher overhead costs per unit produced. When cheese is made in small batches, the fixed costs of production—such as labor, equipment, and facility maintenance—are spread across fewer units, driving up the cost of each individual piece. For example, a cheesemaker might spend the same amount of time and resources to prepare their workspace and equipment for a small batch as they would for a larger one, but the output is significantly less, making each unit more expensive to produce.

Another factor tied to small batch production is the labor intensity involved. Crafting high-quality cheese requires skilled labor, often involving manual processes that cannot be easily automated. In small batches, cheesemakers must dedicate more time and effort per unit, from curdling the milk to aging the cheese. This hands-on approach ensures superior quality but also increases labor costs, which are then reflected in the final price. For instance, flipping and caring for wheels of cheese during the aging process is a time-consuming task that must be repeated for each small batch, adding to the overall expense.

The use of premium ingredients further compounds the cost of small batch cheese production. Artisanal cheesemakers often source high-quality milk from specific breeds of cows, goats, or sheep, which can be more expensive than standard milk. Additionally, they may use organic or locally sourced ingredients, which come at a premium. When these costs are spread across a limited number of units, the expense per unit increases significantly. For example, if a cheesemaker uses milk from grass-fed cows, the cost of that milk is higher, and when only a small batch is produced, that cost is directly absorbed into the price of each cheese.

Aging and storage also play a critical role in the expense of small batch cheeses. Many high-quality cheeses require months or even years to age properly, during which they must be stored in controlled environments. This process ties up resources and space, incurring additional costs for refrigeration, humidity control, and monitoring. In small batch production, these costs are distributed across fewer units, making each cheese more expensive. For instance, a wheel of aged cheddar that has been carefully tended to for 12 months represents a significant investment in time and storage, which is then reflected in its price.

Finally, the economies of scale work against small batch producers. Larger cheese manufacturers can reduce costs per unit by producing in bulk, negotiating better prices for raw materials, and optimizing their production processes. Small batch producers, however, lack these advantages. They often cannot achieve the same cost efficiencies, and as a result, their per-unit costs remain higher. This is why a small batch, handcrafted cheese will almost always be more expensive than its mass-produced counterpart. The limited quantity and focus on quality ensure a superior product but at a premium price.

Feta Cheese and Kidney Disease: A Healthy Match?

You may want to see also

Regulations & Standards: Strict certifications and import tariffs inflate prices

The high cost of premium cheese can be largely attributed to the stringent regulations and standards that govern its production and distribution. In many countries, cheese producers must adhere to strict certifications that ensure quality, safety, and authenticity. For example, the Protected Designation of Origin (PDO) in the European Union guarantees that a cheese has been produced in a specific region using traditional methods and ingredients. Achieving and maintaining such certifications requires significant investment in time, labor, and resources, which ultimately drives up the cost of the final product. These certifications are not merely bureaucratic hurdles but essential measures to preserve the integrity and heritage of traditional cheeses, ensuring consumers receive a product that meets specific standards.

Import tariffs further exacerbate the expense of good cheese, particularly for consumers in countries that rely heavily on imported varieties. Tariffs are taxes imposed on goods crossing international borders, and they can significantly increase the price of imported cheeses. For instance, the United States imposes tariffs on European cheeses, which can range from 10% to 20% or more, depending on the type of cheese. These tariffs are designed to protect domestic cheese producers from foreign competition but have the unintended consequence of making high-quality imported cheeses more expensive for consumers. As a result, cheese lovers often face higher prices when seeking out specialty or artisanal cheeses from other countries.

The combination of strict certifications and import tariffs creates a double-edged sword for cheese producers and consumers alike. Producers must navigate a complex web of regulations to bring their products to market, often requiring specialized knowledge and additional staffing. This compliance adds to the overall production costs, which are then passed on to consumers. For imported cheeses, the added burden of tariffs means that even after meeting the rigorous standards of their country of origin, producers must contend with further financial obstacles to reach international markets. These layers of regulation and taxation contribute to the premium pricing of good cheese, making it a luxury item for many.

Moreover, the enforcement of these regulations and tariffs requires robust inspection and monitoring systems, which are funded by taxpayers and, indirectly, by consumers. Customs agencies and food safety authorities must ensure that imported cheeses comply with local standards, a process that involves detailed documentation, physical inspections, and sometimes laboratory testing. These activities are essential for public health and consumer protection but add to the overall cost structure of the cheese industry. As a result, the price of good cheese reflects not only the craftsmanship and quality of the product but also the extensive regulatory framework that surrounds it.

In summary, the expense of good cheese is significantly inflated by the strict certifications and import tariffs that govern its production and trade. These measures, while crucial for maintaining quality and protecting domestic industries, create financial barriers that increase costs at every stage of the supply chain. From the producer’s compliance with certifications to the consumer’s payment of tariffs embedded in the price, these regulations play a central role in making premium cheese a costly indulgence. Understanding these factors provides insight into why good cheese remains a prized and often expensive commodity in the global market.

Does Bleu Cheese Elevate Your Burger Game? A Tasty Debate

You may want to see also

Frequently asked questions

Good cheese is expensive due to the labor-intensive process, high-quality ingredients, and extended aging times required to produce it. Artisanal cheeses often involve skilled craftsmanship, small-batch production, and premium milk sources, all of which drive up costs.

Yes, the aging process significantly increases the cost of good cheese. Aging requires controlled environments, time (sometimes months or years), and careful monitoring. During this period, cheese loses moisture, reducing its final weight, while labor and storage costs accumulate.

Imported cheeses are often more expensive due to additional costs like transportation, import taxes, and customs fees. Additionally, cheeses from regions with specific traditions or protected designations (e.g., Parmigiano-Reggiano) adhere to strict production standards, further increasing their price.