Camembert is a soft, creamy French cheese with a distinctive bloomy, edible rind. It is one of France's most iconic cheeses and is now internationally known, with many local varieties made around the world. The cheese is made from cow's milk, which is heated and has enzymes added to it to cause coagulation. The curds are then cut into cubes and put into moulds to drain and form a rind. The cheese is then salted and ripened, developing stronger flavours and aromas as it ages. The process of making Camembert is complex and challenging, and the cheese has a rich history, with its origins in Normandy, France.

| Characteristics | Values |

|---|---|

| Place of origin | Normandy, France |

| Texture | Soft, spreadable, creamy |

| Taste | Stronger, slightly sour, sometimes chalky |

| Curing agent | Rennet |

| Milk source | Cow |

| Milk type | Raw, unpasteurized |

| Milk quantity | 4 litres of milk for 4 small cheeses |

| Milk treatment | Heated, enzymes added |

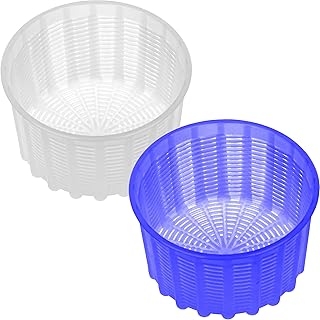

| Coagulation | Curds formed, scooped and put into round molds |

| Mold | Penicillium camemberti |

| Ripening time | Minimum of three weeks |

| Packaging | Wrapped in paper, placed in wooden boxes for transport |

Explore related products

What You'll Learn

Milk from Norman cows

Normandy is credited with being the birthplace of Camembert, a soft, creamy French cheese. The milk used in the production of Camembert is sourced from Norman cows, which are fed an organic diet. The cows produce 15 to 20 litres of milk each day, and this milk is then transported directly to the dairy without being refrigerated. It is left overnight, and in the morning, it is heated, with enzymes added to facilitate coagulation.

Norman cows, also known as "Normandes", are a breed of cattle native to the Normandy region of France. They are known for their distinctive red and white markings and their ability to produce high-quality milk that is particularly well-suited for cheese-making. The milk from Norman cows is rich in butterfat and protein, which gives Camembert its characteristic creamy texture and flavour.

The process of making Camembert cheese begins with the milk being left to coagulate. Once curds begin to form, they are carefully scooped out and placed into round moulds. The curds then undergo a process of retraction, where natural bacteria and acid cause them to release water and develop flavourful and aromatic compounds. This step is crucial in giving Camembert its unique taste and texture.

The milk from Norman cows is essential to the character of Camembert cheese. In fact, the variety named Camembert de Normandie can only be made from the raw, unpasteurized milk of Norman cows, and it has been granted a protected designation of origin. This means that only cheeses made in certain parts of Normandy from the milk of Norman cows can be labelled as Camembert de Normandie.

While most Camembert produced in France today is made from pasteurized milk due to industry changes and hygiene regulations, the traditional method uses raw milk. This raw milk cheese, made from the milk of Norman cows, offers an explosion of flavour that cannot be reproduced in pasteurized Camembert, according to cheese producers.

The Magic Ingredients Behind Delicious Queso Cheese

You may want to see also

Coagulation and moulding

Coagulation is a vital step in Camembert cheese production, where milk proteins are curdled to form a solid mass. This step is essential for the development of the cheese's texture and flavour. Coagulation can be achieved through the use of rennet or bacterial enzymes, both of which play a significant role in transforming liquid milk into a semi-solid state. Rennet, a complex mixture of enzymes, is traditionally used in cheese-making. It is derived from the stomach lining of young calves and contains the enzyme rennin. When added to milk, rennin initiates a rapid and specific reaction with the milk proteins, primarily casein. This reaction causes the milk proteins to denature and aggregate, forming a gel-like structure. The process is highly controlled, as the concentration and temperature of rennet application are critical factors.

Bacterial enzymes, on the other hand, offer an alternative approach to coagulation. Microbial cultures, such as those from Lactobacillus and Streptococcus thermophilus, produce specific enzymes that can also curdle milk. These enzymes, including proteases and lipases, break down milk proteins and fats, respectively. Bacterial coagulation is often preferred in modern cheese-making due to its consistency and predictability. The enzymes are carefully selected and controlled to ensure a uniform curd structure, which is essential for the even ripening of Camembert. The choice between rennet and bacterial enzymes depends on various factors, including regional traditions, availability, and personal preferences. Some cheese makers opt for a combination of both methods to achieve the desired curd structure and flavour.

After the coagulation process, the curds are cut into small cubes and left to rest to allow the whey to be released. The curds should have a drier exterior with a slight skin formed while still retaining lots of moisture inside. The curds are then shaped into rounds and placed in moulds, where they are covered with a thin layer of brine, which encourages the growth of the Penicillium camemberti mould. This mould not only gives Camembert its characteristic white rind but also plays a vital role in the ripening process, enhancing the cheese's flavour and texture. The mould used in Camembert production is carefully cultivated and controlled to ensure the desired texture and flavour profile.

The cheese is then aged, typically for several weeks, during which it develops its rich, earthy flavour and soft, creamy interior. During this time, the cheese is turned several times to allow uniform drainage and the growth of the mould. The ripening stage is crucial for the development of the cheese's sensory properties, with the mycelium development of G. candidum and P. camemberti contributing to the bloomy aspect and typical sensory properties of Camembert-type cheese.

Cheese Cultures: Cow Milk's Role Explained

You may want to see also

Ripening and rind formation

Once the curds have been formed and placed into moulds, the Camembert cheese is then ready to be ripened. The surface of each cheese is sprayed with an aqueous suspension of the mould Penicillium camemberti. The cheese is then left to ripen for a minimum of three weeks, although some recipes suggest two weeks is enough. This process, known as affinage, produces the distinctive bloomy, edible rind and creamy interior texture characteristic of the cheese. The rind is made by communities of beneficial microbes, including the bacteria Penicillium candidum, slowly ripening the cheese from the outside in.

As the microbes break down the fats and proteins in the cheese, the area beneath the rind will form a soft, liquid cream line. As it ages, the cream line takes over more of the interior of the cheese, and the wheel will develop stronger flavours and aromas. The cheese is typically sold at about one month old but can be aged longer depending on the preferences of the eater. If the cheese is left to ripen for too long, it will contain an unpleasant, excessive amount of ammonia, produced by the same microorganisms required for ripening.

To ensure the cheese does not ripen too quickly, it is wrapped in ripening paper or cheese film. The cheese wrap helps to slow the mould so that it doesn't ripen too fast. It may take until the fourth week to fully mature, but it should still be checked at the three-week mark. If the cheese is matured above 7°C, the flavour will be overpowering.

In the past, the colour of the Camembert rind was a matter of chance, most commonly blue-grey, with brown spots. From the early 20th century onwards, the rind has been more commonly pure white, but it was not until the mid-1970s that pure white became standard.

Culver's Cheese Curds: What's the Secret Recipe?

You may want to see also

Explore related products

Packaging and transportation

Once the cheese has been made and is ready for sale, it needs to be packaged and transported in a way that preserves its soft, ripe condition. Traditionally, Camembert was sold in thin, round, wooden containers made from poplar. However, with the invention of mass production, Camembert began to be packaged in cardboard boxes, cartons, and tin cans with ring-pull tabs. The cardboard boxes are typically reserved for low-cost Camemberts. The product inside cardboard boxes is the same as that in wooden containers, wrapped dry in a paper/foil wrapper, and not immersed in brine or oil.

Before packaging, the cheese is wrapped in ripening paper, which helps to slow the mould so that it doesn't ripen too quickly. The cheese should be covered in a consistent white mould, with no black mould. If there is any black mould, it should be picked off with a sterile knife. The cheese is then wrapped in cheese film or cheese paper, which may be placed in wooden boxes for transport.

Camembert is a soft, ripe cheese that does not travel well. However, with the invention of mass-produced round wooden boxes, the cheese could be safely and quickly moved to major markets via the railroads. This allowed the cheese to gain fame and become a well-known product beyond its region of origin.

Polly-O Cheese: Where Is It Made and Why There?

You may want to see also

Importation and sale

The importation and sale of Camembert cheese is a complex process that involves adhering to various regulations and standards. Here is a detailed overview of the key aspects:

Regulations and Standards

The importation and sale of Camembert cheese are subject to strict regulations and standards. These regulations are in place to ensure the safety and quality of the cheese, as well as to protect consumers from any potential health risks. One notable example is the issue of hygiene regulations, which have impacted the importation and sale of Camembert cheese in certain countries, such as the United States. To comply with these regulations, a variant of Camembert made from pasteurized milk is sold in the US instead of the traditional raw milk version.

Packaging and Transportation

The packaging and transportation of Camembert cheese play a crucial role in maintaining its quality and freshness during importation and sale. Traditionally, Camembert is wrapped in paper and placed in thin, round wooden containers made from poplar wood. Modern packaging variations include cartons and tin cans with ring-pull tabs, which offer convenience and extended shelf life. The choice of packaging material and transportation method can vary depending on the destination country's regulations, climate, and consumer preferences.

Import Procedures and Distribution

Importing Camembert cheese into a country involves navigating customs procedures, tariffs, and other import regulations. Organizations like the Cheese Importers Association of America assist importers by providing valuable information and support in facilitating the efficient import of dairy products, ensuring compliance with relevant laws and regulations. Importers must also establish a distribution network to deliver the imported cheese to retailers and consumers, ensuring proper storage and handling throughout the supply chain.

Retail and Consumer Sales

The sale of Camembert cheese to consumers typically occurs through retail outlets such as specialty cheese shops, supermarkets, and online platforms. Retailers play a crucial role in storing and displaying the cheese properly, providing accurate product information, and ensuring its freshness. Consumers can purchase Camembert cheese for personal consumption, often attracted by its distinctive flavour, texture, and cultural associations.

International Variations

It is worth noting that Camembert cheese is produced in various countries worldwide, each with its own unique twist on the traditional French cheese. For example, similar cheeses are produced in Hungary, the Czech Republic, and Slovakia under different names. These international variations may have different import and sales regulations, impacting their availability and distribution in specific markets.

Dairy-Free Cheese at Papa Murphy's: What's in It?

You may want to see also

Frequently asked questions

Normandy, France, is credited with being the birthplace of Camembert. The cheese was reputedly first made in 1791 by Marie Harel, a farmer from Normandy.

Camembert is a soft, spreadable, creamy French cheese made from cow's milk.

First, milk is heated, and enzymes are added to it. The milk is then left to coagulate. Once curds begin to form, they are put into round molds where the natural bacteria and acid cause the curds to retract and squeeze out water. The cheese is then sprayed with an aqueous suspension of the mold Penicillium camemberti and left to ripen for a minimum of three weeks.