Cheddar cheese is not naturally orange. The colour comes from the addition of various dyes, the most common of which is annatto, a food colouring made from the seeds of the achiote tree. In the past, dyes such as saffron, marigold, and carrot juice were used to give cheddar its distinctive orange hue. The colour of cheddar cheese is so important because the orange colour came to be associated with high-quality cheese.

| Characteristics | Values |

|---|---|

| Natural colour of cheese | Shades of white to creamy yellow |

| Reason for the orange colour | Orange pigment added to distinguish high-quality cheese |

| Source of orange pigment | Annatto seeds, marigold, carrot juice, saffron, paprika |

| Reason for adding orange pigment | To standardise colour throughout the year |

| Beta-carotene | Found in grass, imparts orange colour to milk |

Explore related products

What You'll Learn

Beta-carotene in cow's milk

Beta-carotene is a natural pigment found in plants that gives carrots their orange colour. It is also found in cows' milk, with pasture-fed cows producing milk with higher levels of beta-carotene in the spring when their diet consists of fresh grass. This beta-carotene lends an orange pigment to the milk, which deepens to a yellow colour when used to make cheese.

Beta-carotene is a type of carotenoid, which is a precursor of retinol, or Vitamin A, in animals. In cows, beta-carotene is found in the milk and plasma. The concentration of beta-carotene in milk is dependent on its dietary supply, with the level of intake generally controlling the concentration in the milk. This means that cows with a diet high in beta-carotene will produce milk with a higher concentration of beta-carotene, resulting in a more orange colour.

The colour of milk and cheese has been linked to "'natural'" feeding and grazing production systems, with a yellow colour in milk associated with pasture. This has implications for consumer perception, as milk with a higher carotenoid concentration may be viewed more positively by consumers.

In addition to its impact on colour, beta-carotene also has a positive effect on cow health and fertility. Supplementation of beta-carotene in dairy cows has been shown to reduce mastitis and improve reproductive performance, particularly in tropical dairy cows. However, there are also studies indicating that a diet high in beta-carotene may have adverse effects on the fertility of dairy cows, with a potential reduction in conception rates.

The Basic Nacho Cheese Recipe: Simple Ingredients, Delicious Flavor

You may want to see also

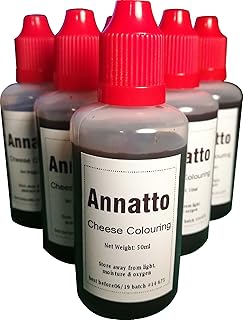

Annatto seeds as a dye

The colour orange has become synonymous with cheddar cheese, but it is not naturally orange. The orange hue comes from the addition of annatto seeds, which are ground into a red powder and used as a dye. This tradition began in the 17th century when cows fed on a diet of high-quality grass produced milk with higher levels of beta-carotene, resulting in cheese with a deeper yellow colour. This colour became associated with high-quality, better-flavoured cheese, and so cheesemakers of lower-quality cheese began adding natural dyes to mimic the hue.

Annatto seeds come from the achiote tree, which grows in tropical regions of Central and South America. The seeds are dried and ground into a powder, which is then added to cheese to give it a consistent orange colour. This practice has been used for over 200 years to ensure a uniform colour throughout the year, as the natural colour of cheese varies depending on the diet of the cows.

The addition of annatto seeds does not affect the flavour or texture of the cheese, but rather gives it the familiar orange colour that consumers expect. The use of annatto as a dye in cheese is particularly common in the United States, where it is used to distinguish the product from the typically white cheese made in New England and New York.

Annatto has been used as a dye in other cheeses as well, such as Red Leicester, to distinguish it in the marketplace as a high-quality cheese. The use of annatto in Red Leicester gives it a unique, bitter coppery flavour, which also contributes to its status as a specialty cheese.

In summary, annatto seeds are used as a natural dye to give cheddar cheese its distinctive orange colour. This tradition began as a way to indicate higher-quality cheese and has persisted due to consumer expectations and the association of orange with cheddar cheese.

Vegan Cheese Secrets: Domino's Plant-Based Option Explained

You may want to see also

Visual branding

The origin of the orange colour dates back to 17th-century England, where cows fed on grass rich in beta-carotene produced milk with a higher beta-carotene content, resulting in a deeper yellow colour. This hue became associated with high-quality cheese, and cheesemakers soon began to add natural dyes such as saffron, marigold, and carrot juice to enhance the colour and signify quality.

As the trend of orange cheddar spread, including to the United States, the colour became a key part of the cheese's visual branding. Cheesemakers sought to maintain a consistent colour throughout the year to distinguish their product and create a recognisable brand. The use of natural and chemical dyes intensified the orange colour, and today, annatto, a food colouring made from the seeds of the achiote tree, is commonly used to achieve the expected hue.

The colour orange has become so strongly associated with cheddar cheese that it has influenced the branding and colouring of other cheese products and snacks, such as American cheese and Cheetos. The visual branding of cheddar cheese as orange has been so successful that it has shaped consumer expectations and preferences, with many consumers now expecting and preferring the bright orange variety.

Cheese Sauce: The Magic of Milk, Butter, and Flour

You may want to see also

Explore related products

Seasonal variation in milk colour

The colour of milk produced by cows can vary depending on their diet and the quality of their grazing fields. In the early days of cheddar cheese, cheese lovers preferred the flavour of cheese made from milk with higher beta-carotene levels, as it was considered higher quality and commanded a higher price. This created an association between the yellow-orange colour and higher-quality cheese.

To meet the demand for yellow-orange cheese, cheesemakers began to add natural dyes to their white cheeses, such as saffron, marigold, and carrot juice. This practice, known as "early visual branding", helped maintain the visual recognition factor of their regional cheese. The addition of these dyes resulted in a more uniform colour throughout the year, as the natural colour of milk can vary with the seasons.

Today, many manufacturers who dye their cheddar use annatto seed, a natural food colouring made from the seeds of the achiote tree, which grows in tropical regions in Central and South America. Annatto has been used to dye cheese for more than 200 years and gives cheddar a consistent colour year-round. It is important to note that the colour of cheddar cheese does not affect its flavour or texture, and consumers can choose between orange or white cheddar based on their preference.

Vegan Cheese: How It's Made and What's in It

You may want to see also

Early American settlers

Cheddar cheese was a significant part of the early North American export market. From the mid-1600s, New England exported large quantities of cheese to supply the expanding sugarcane plantations in the West Indies. By 1790, American-made cheddars were being exported back to England.

The colour of cheddar cheese was, and still is, important to its perceived quality. In the early days of cheddar, cheese lovers preferred yellow cheddar, and cheese shops could charge more for their yellow cheddar cheese. English cheesemakers in the 17th century would skim off the cream from the milk to sell separately or make butter from it, leaving them with low-fat cheese made from white milk. To pass off this cheese as a high-quality, full-fat product, they would add colourings such as saffron, marigold, carrot juice, and later, annatto, a natural food colouring made from the seeds of the achiote tree.

Annatto was also used by early American cheesemakers to ensure their cheddar had a consistent orange colour year-round, as the colour of cheese made from cow's milk can vary depending on the time of year and the diet of the cows. In the summer, cows that graze on grass high in beta-carotene will produce more orange-tinted milk, while in the winter, when cows eat more hay, the beta-carotene levels drop, and the cheese made from their milk will be whiter or more yellow.

Menonita Cheese: Crafting the Unique Flavor Experience

You may want to see also

Frequently asked questions

In its natural state, cheese is white to creamy yellow. The orange colour comes from the addition of annatto, a food colouring made from the seeds of the achiote tree.

The colour orange became associated with cheese and its high quality. Adding annatto to cheese gives it a uniform colour throughout the year.

Annatto is a red powder made from the seeds of the annatto tree, which grows in tropical regions in Central and South America.

By the 1600s, farmers were skimming off rich yellow cream for butter production, leaving them with white cheddar. To maintain the visual recognition of their regional cheese, cheesemakers began to add dying agents like carrot juice, saffron, and marigold.

No, the colour doesn't affect the flavour or texture of the cheese. The difference between cheddars is found in the cheesemaking process: the culture used, milk choice, manufacturing method, and aging.