Cheshire cheese is one of the oldest recorded named cheeses in British history, dating back to Roman times. It is a dense, crumbly cheese with a mildly salty, tangy flavour and a yellow-orange colour. But how is it made? While there is little information on the current production process, we do know that traditional methods include the use of open vats and manual curd handling. The cheese is made from raw cow's milk and animal rennet, with the addition of annatto imparting its distinctive colour. The maturation process takes around 12 weeks, resulting in a grassy, piquant flavour.

| Characteristics | Values |

|---|---|

| Texture | Dense, moist, crumbly |

| Taste | Mild, salty, tangy, buttery, slightly cheesy |

| Colour | Pale orange, yellow-orange, deep orange |

| Milk | Cow's milk |

| Rennet | Animal rennet, vegetarian rennet |

| Maturation | 12 weeks, 2-3 months, 6 months to a year |

| Manufacture | Open vats, manual curd handling |

| Shape | Cloth-wrapped drums |

| Diameter | 7-8 inches |

| Height | 14 inches |

| Weight | 15 lbs |

Explore related products

What You'll Learn

Cheshire cheese is made from raw cow's milk

Cheshire cheese is one of the oldest cheeses made in Britain. It is believed to have been made since Roman times and was mentioned in the Domesday Book of 1086. It is produced in the English county of Cheshire and the neighbouring counties of Denbighshire, Flintshire, Shropshire, and Staffordshire.

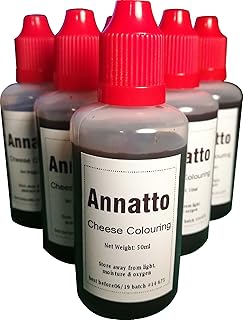

The cheese gets its characteristic orange colour from annatto, a natural dye. The addition of annatto also contributes to the cheese's distinct flavour. Cheshire cheese is defined by its moist, crumbly texture and mild, salty taste. It is considered less creamy than other cheeses like Stilton and has a slight tang.

The process of making Cheshire cheese involves using open vats and manual curd handling. The curds are allowed to sit at warm temperatures for a day to drain and develop the final acid before being salted and pressed. The maturation process takes approximately 12 weeks, although some sources suggest ripening for 2-3 months. The cheese is then typically wrapped in cloth and sometimes waxed.

Cheese-Making Basics: A Step-by-Step Guide

You may want to see also

The cheese is coloured with annatto

Red Cheshire, coloured with annatto, was originally developed in the hills of North Wales and sold to travellers on the road to Holyhead. The colour was added to distinguish the cheese from those made in the traditional Cheshire region. This trade was so successful that travellers came to believe that all Cheshire cheese was orange, and producers in Cheshire were obliged to dye their cheese to match the expectations of the market.

Annatto is also used to colour other cheeses, such as Red Leicester, and it is often added to butter and margarine to give them a more appealing yellow colour. The dye is flavourless, so it does not affect the taste of the cheese.

Cheshire cheese comes in three varieties: red, white, and blue. The original plain white version accounts for most of the production, but the red variety is also popular.

Cheese Nips: Are They Still Being Made?

You may want to see also

It is formed into cloth-wrapped drums

Cloth wrapping is a traditional method of protecting cheese during maturation in the UK. Cheshire cheese is formed into cloth-wrapped drums, which are typically 14 inches high with a diameter of 7-8 inches, weighing about 15 lbs. The maturation process takes approximately 12 weeks, although some sources state that the cheese is aged for 6 months up to a year. The drums are usually wrapped in cloth and rarely waxed over the cloth. The cheese is ripened and protected while enzymes break down the curd to form complex flavours.

Farmhouse Cheshire cheese is made from raw (unpasteurized) cow's milk, and the milk must be produced by Friesian cattle in the Cheshire area. The colour, size, shape and aging of the cheese are not regulated, and it comes in three varieties: red, white and blue. The original plain white version accounts for most of the production.

Red Cheshire, which is a deep orange colour, was developed in the hills of North Wales and sold to travellers on the road to Holyhead. The colour was added to distinguish the fact that it was not made in the traditional Cheshire region. However, the trade was so successful that travellers came to believe all Cheshire cheese was orange, and producers in the home county were obliged to dye their cheese to match market expectations. The orange colour is achieved by adding annatto, which also imparts a warm, sunrise hue to the cheese.

Cheshire cheese is one of the oldest recorded named cheeses in British history, dating back to Roman times and mentioned in the Domesday Book of 1086. It was considered Britain's finest cheese and was the most popular type of cheese on the market in the late 18th century.

The Evolution of Chuck E. Cheese: A Historical Overview

You may want to see also

Explore related products

It is aged for at least 12 weeks

Cheshire cheese is aged for a minimum of 12 weeks. This maturation process is essential to developing the cheese's distinctive flavour and texture. During this time, enzymes work to break down the curds, creating complex flavours that cannot be achieved without proper ageing.

The ageing process for Cheshire cheese has evolved over time, with different techniques employed to protect the cheese during maturation. Traditionally, Cheshire cheese was wrapped in cloth, and this method is still used by some cheesemakers today, passed down through generations. The cloth wrapping helps to safeguard the cheese as enzymes break down the curd, contributing to the development of its unique characteristics.

The ageing duration for Cheshire cheese can vary, with some sources mentioning ageing times of 2-3 months, while others suggest 6 months to a year. The length of ageing influences the final moisture content of the cheese, with longer-aged cheeses having a drier texture. The moisture in Cheshire cheese is a defining feature, contributing to its moist, crumbly texture.

The ageing process also affects the flavour of the cheese. Cheshire cheese is known for its mild, salty, and tangy taste, with grassy and piquant notes developing during maturation. The soil in the Cheshire basin, which contains an underlying layer of bedrock salt, also contributes to its distinctive flavour.

Cheese Whiz: What's in the Squeeze?

You may want to see also

It is dense, crumbly, and mildly salty

Cheshire cheese is a dense, crumbly, and mildly salty cheese. It is one of the oldest recorded named cheeses in British history, dating back to Roman times and mentioned in Thomas Muffet's Health's Improvement (c. 1580) and the Domesday Book of 1086. It is made using raw or pasteurized cow's milk and animal or vegetarian rennet, and is typically ripened for 2-3 months, although some versions are aged for up to a year.

The cheese gets its distinctive orange colour from annatto, a natural dye. The texture of Cheshire cheese is drier than Cheddar, but it is similarly crumbly. It has a mild, salty taste with a slightly tangy flavour. The Cheshire family of cheeses includes other crumbly cheeses from the North of England, such as Wensleydale and Crumbly Lancashire.

The traditional method of making Cheshire cheese involves open vats and manual curd handling. The curds sit at warm temperatures for a day to drain and develop the final acid before being salted and pressed. The cheese is then either cloth-wrapped or waxed, with each cheesemaker employing their own technique passed down through generations.

Cheshire cheese was once considered Britain's finest cheese, and it was the most popular type of cheese on the market in the late 18th century. It was favoured by the Royal Navy, which ordered ships to be stocked with Cheshire and Gloucester cheeses in 1758. By the 19th century, Cheshire cheese production had reached an estimated 10,000-12,000 tonnes per year.

Cheese Mold Magic: Bacteria's Role Explained

You may want to see also

Frequently asked questions

Cheshire cheese is a dense and crumbly cheese produced in the English county of Cheshire and four neighbouring counties. It is one of the oldest recorded named cheeses in British history, dating back to Roman times.

Cheshire cheese is traditionally made from raw (unpasteurized) cow's milk and animal rennet. Some varieties use vegetarian rennet and pasteurized cow's milk.

Cheshire cheese is known for its mildly salty, tangy flavour. It has a moist, crumbly texture and is often described as "rustic" and "mild".

Cheshire cheese is traditionally made using open vats and manual curd handling. The curds are allowed to sit at warm temperatures for a day to drain and develop the final acid before being salted and pressed. The cheese is then aged for 2-3 months or up to a year.

![The Practice of Cheddar Cheese Making / by George Gibbons., Bound With: The Practice of Cheshire Cheese Making & Practice of Stilton Cheese 1892 Volume und wi: e pracce of Che [Leather Bound]](https://m.media-amazon.com/images/I/61FbOFgXaEL._AC_UL320_.jpg)