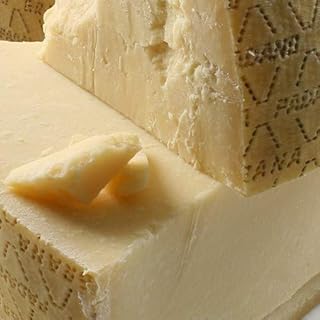

Grana Padano is a hard, crumbly-textured cheese originating in the Po Valley in northern Italy. It is made from unpasteurized cow's milk that is semi-skimmed and cooked. The process of making Grana Padano involves mixing the milk with whey and animal-derived rennet to form curd, which is then shaped into wheels and soaked in brine. This initiates the aging process, which can last anywhere from nine to 20 months. The cheese gets its name from its grainy texture and the region it is produced in.

Explore related products

What You'll Learn

Milk from cows milked twice a day

Milk is essential to making Grana Padano cheese. Cows are milked twice a day, once in the morning and once in the evening. The milk produced in the morning is typically lower in fat content than the milk produced in the evening. The two types of milk are mixed together to create a semi-skimmed milk that is left unpasteurised.

The cows that produce the milk for Grana Padano are free-range and allowed to graze on fresh forage and silage. The milk is produced in the Po Valley in Italy.

The evening milk is skimmed to remove the surface layer of cream and mixed with the fresh milk produced in the morning. This mixture is then combined with natural whey and animal-derived rennet to form curd. The whey is made the day before and is full of lactic acid bacteria, which is essential to transforming the milk into cheese.

The milk, whey, and rennet mixture is placed in traditional bell-shaped copper cooking cauldrons or vats. Each cauldron produces two wheels of cheese, called "twin wheels". The milk is then brought to a temperature of 31-33°C (88-91° F) to stimulate the natural bacteria, and the calf rennet is added. The curd is separated and allowed to settle. The broken curd is set in a wheel-shaped mould and soaked in brine for at least two weeks.

Vegan Cheese Sauce: The Magic Ingredients Revealed

You may want to see also

Curd formation and coagulation

To make Grana Padano, the first step is to mix the morning and evening milk. Cows are milked twice a day, once in the morning and once in the evening; typically, morning milk is lower in fat content. These two milks are mixed together to create a semi-skimmed milk that is left unpasteurised.

The curd formation and coagulation process begins by pouring the milk mixture into copper kettles/cauldrons/vats, along with natural whey and animal-derived rennet. The whey is produced the day before and is full of lactic acid bacteria, which triggers the transformation of milk into cheese. The milk is then heated to a temperature of 31-33°C (88-91° F) to coagulate the milk and form the curd. The curd is cut to produce granules with the size of rice grains, which gives the cheese its characteristic texture. The granules are then warmed to a maximum temperature of 53-56°C (127- 136° F. Once this temperature is reached, the cooking is completed, and the curd granules begin to settle at the bottom of the copper cauldron. The curd granules are left to rest in the copper cauldron, immersed in the whey, for a maximum of 70 minutes from the end of the heating phase, so that they aggregate to form a compact mass.

Fat-Free Cheese: How is it Made?

You may want to see also

Shaping and salting

After the curd has been heated and allowed to settle, it is set in a wheel-shaped mould and soaked in brine for at least two weeks. This process is called salting, and it extracts moisture from the cheese and begins the ageing process. The length of the ageing process varies, with a minimum of nine months and a maximum of 20 months, or even up to two years.

After two days of being immersed in water, the cheese wheel rises from a minimum of 14 days to a maximum of 30 days, and then passes into a warm chamber where it will dry. The last phase is the ageing, which can be of three types: from nine to 16 months for a softer and almost granular Grana Padano; more than 16 months, with more evident graininess and more presence of calcium crystals; and over 20 months, which is the "Grana Padano Riserva", extremely grainy and with a high presence of calcium crystals.

The salting and ageing processes are crucial in developing the cheese's flavour and texture. The ageing process can also be influenced by the production process, which differs from that of Parmesan in that cattle producing the milk may be fed high-quality silage. This "favours the contamination of raw milk by spore-forming clostridia". Lysozyme is added to the vats to prevent late blowing (swelling during the ripening process) that may result from butyric fermentation, and is an anti-clostridial agent.

The Making of Mini Babybel Cheese

You may want to see also

Explore related products

Aging for at least nine months

After the curd has been heated, it is left to rest in the copper cauldron, immersed in whey, for a maximum of 70 minutes. This allows the curd granules to aggregate and form a compact mass. After this, the cheese is treated to a temperature meant to stimulate the natural bacteria, and the curd is separated and allowed to settle. The broken curd is then set in a wheel-shaped mould and soaked in brine for at least two weeks. This brine solution is crucial, as it encourages the elimination of excess whey and the formation of the crust, as well as adding flavour to the cheese.

After the salting is finished, the wheels are ready for ageing. Grana Padano is aged for a minimum of nine months and up to 20 months. It is inspected after nine months, and if it passes the quality tests, it is given the title of Grana Padano and fire-branded with the trademark. If it is left to age for longer, it becomes more crumbly and gains a more pronounced taste. After 16 months, the cheese is extremely grainy and has a high presence of calcium crystals. This is called "Grana Padano Riserva".

Grana Padano is nearly lactose-free due to its ageing process, which also leads to a reduction of lipids. It has a low moisture content, and when stored well, can last almost indefinitely in the fridge. It is best stored at about 40°F in a sealed container or bag, and can also be frozen, although this may result in a mealy texture.

Who Invented Cheese on Foster's Home?

You may want to see also

Branding and packaging

Grana Padano cheese is made in the Po Valley area of northern Italy. It has been produced since the 12th century when it was developed by Cistercian monks of the Chiaravalle Abbey. The name "Grana Padano" is derived from the Italian word "grana", meaning "grain", which refers to the grainy texture of the cheese, and "padano", meaning "from Val Padana" (the Po Valley).

The cheese is produced according to strict regulations and has been registered as a denominazione di origine controllata (DOC) in 1955 and as a Protected Designation of Origin (PDO) in 1996. This means that the recipe and process of making Grana Padano are protected, and it can only be labelled as such if it is produced in a specific part of Italy. The PDO status also ensures that the quality of the cheese is closely monitored and that the production process, from the cows' fodder to the branding of the wheels, is carefully regulated.

The branding of Grana Padano cheese is important to ensure its authenticity and quality. Each wheel of cheese is fire-branded with the Grana Padano trademark if it passes quality tests. The trademark is a guarantee of the cheese's origin, production process, and quality. The branding also allows for traceability, so that the cheese can be traced back to its specific production batch and region.

The packaging of Grana Padano cheese is also important to preserve its freshness and flavour. The cheese should be packaged in a sealed food storage container or food storage bag to prevent moisture from collecting. It is recommended to store the cheese at a temperature of about 40 degrees Fahrenheit. When stored properly, Grana Padano cheese can last almost indefinitely in the fridge. However, it is not recommended to freeze the cheese as it can affect its texture.

Grana Padano cheese is typically sold in three different ripening stages: "Grana Padano" (9 to 16 months), "Grana Padano oltre 16 mesi" (over 16 months), and "Grana Padano Riserva" (over 20 months). Each ripening stage offers a different texture and flavour profile, from a softer and almost granular cheese to a more crumbly and full-flavoured product. The packaging for each stage may vary slightly to reflect the different characteristics of the cheese.

Philly Cheese Steak: The Ultimate Guide to Ingredients

You may want to see also

Frequently asked questions

The ingredients used to make Grana Padano are milk, natural whey, and calf rennet.

Grana Padano is made by first mixing the milk from the morning and evening milkings to create semi-skimmed milk. This milk is then mixed with the natural whey and calf rennet to form curd. The curd is then heated and cut to produce granules, which are then shaped into wheels and soaked in brine. The wheels are then aged for at least nine months.

Grana Padano can last a long time without spoiling, and is sometimes aged for up to two years. When stored well, it can last almost indefinitely in the fridge.