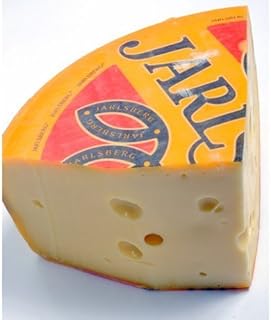

Jarlsberg is a mild, semi-soft, Swiss-type cheese made from cow's milk. It has a distinctive yellow, buttery texture and a nutty flavour. The cheese was first produced in the 1950s in Norway and is now also made in Ireland and the US state of Ohio. The exact recipe is a closely guarded trade secret, but some of the steps involved in making the cheese include heating milk, adding bacterial culture, cutting curds, and waxing.

| Characteristics | Values |

|---|---|

| Origin | Norway |

| Main Ingredient | Cow's milk |

| Texture | Semi-soft |

| Flavour | Mild, nutty, buttery, sweet |

| Colour | Yellow |

| Rind | Yellow wax |

| Weight | 10-kilogram (22 lb) wheels |

| Diameter | 330 millimetres (13 in) |

| Height | 95 to 105 millimetres (3.7 to 4.1 in) |

| Minimum Age | 3 months |

| Holes | Large, irregular |

| Recipe | Secret |

| Manufacturer | Tine SA |

| Founder | Ole Martin Ystgaard |

Explore related products

What You'll Learn

Heating the milk

To make Jarlsberg cheese, the milk must be heated to 92 °F or 33 °C. This can be done by placing the milk in a pot or sink of very warm water. If using a pot on the stove, heat the milk slowly and stir it well. Alternatively, a double boiler can be used. Once the milk reaches the target temperature, turn off the heat.

The next step is to add the culture. To prevent the powder from caking and sinking in clumps, sprinkle the powder over the surface of the milk and allow it to rehydrate for about 2 to 3 minutes before stirring it in. Cover the milk and allow it to rest for 30 minutes at the target temperature. It is okay if the temperature drops a few degrees during this time. The milk will begin to thicken at around 15 minutes, but it is important to allow a firm curd to develop before cutting.

While waiting for the curd to form, sanitise the mould and cloth for the final cheese. Once the curd is firm, use a long knife to cut the surface in a crosshatch pattern to a depth of about one inch. Let this rest for 3 to 5 minutes while the whey rises in the cuts. Then, use a ladle, spoon, or thin wired whisk to cut the curd into large pea-sized pieces as evenly as possible. Continue stirring for about 20 minutes to release the whey and firm up the curd before the final heating.

Cheesy Dinosaur: What's in a Name?

You may want to see also

Adding bacterial culture

The process of making Jarlsberg cheese involves adding bacterial culture to cheese milk. This technique was developed by Professor Ole Martin Ystgaard and his students at the Dairy Institute of the Agricultural University of Norway in the 1950s. The exact nature of the bacterial culture and the process of making Jarlsberg cheese is a closely guarded trade secret. However, here is a general overview of the process of adding bacterial culture when making Jarlsberg cheese at home.

Firstly, heat the milk to around 33°C (92°F) or 37°C (98°F). This can be done by placing the milk in a pot or sink of very warm water, or in a double boiler, ensuring that the milk is heated slowly and stirred well. Once the milk has reached the desired temperature, turn off the heat.

Next, sprinkle the bacterial culture powder over the surface of the milk. This is done to prevent the powder from caking and sinking in clumps. Allow the powder to rehydrate for about 2-3 minutes, then stir it thoroughly in an up-and-down motion without breaking the surface of the milk. Cover the milk and allow it to rest for 30 minutes at the target temperature. During this time, the culture will begin to work, and the milk will start to thicken and coagulate the curd. It is important to maintain the warmth of the milk during this period, but it is okay if the temperature drops a few degrees.

After 30 minutes, the milk should have developed into a firm curd. At this stage, you can begin cutting the curd. Use a long knife to cut the surface in a crosshatch pattern to a depth of about one inch. Let this rest for 3-5 minutes, then use a ladle, spoon, or thin wired whisk to cut the curd into large pea-sized pieces as evenly as possible. Continue stirring for about 20 minutes to release whey and firm up the curd before the final heating.

The next step is to dry out the curds by slowly increasing the heat to 39°C (102°F). This is done by removing a portion of the whey and adding back warm water over a period of 20-30 minutes. First, allow the curd to settle to the bottom of the pot and then remove 30% of the whey. Stir the curds well, and then add back a volume of warm water that is about half of what was removed. The water should be added slowly while stirring continuously, just enough to keep the curds separate and moving. The final temperature should be about 39°C (102°F).

Finally, hold the curd at the final cook temperature while stirring for about 30-45 minutes. This step will allow the curd to further release whey and firm up before it is transferred to a cheese mould for pressing and shaping.

Feta Cheese: Animal Origins and Taste

You may want to see also

Curdling and cutting

The process of curdling and cutting the cheese is a crucial step in cheesemaking. For Jarlsberg cheese, the milk needs to be heated to around 92°F or 33°C. Once the milk has reached the desired temperature, it is important to maintain this warmth for about 30 minutes while the culture works its magic and the rennet coagulates the curd. During this time, the milk will start to thicken, and a firm curd will develop—this is when the cutting begins.

Use a long knife to cut the surface of the curd, creating a crosshatch pattern with cuts about one inch apart. Allow the curd to rest for 3 to 5 minutes, giving the whey time to rise through the cuts. Then, use a ladle, spoon, or thin wired whisk to cut the curd into large pea-sized pieces as evenly as possible. It is important to be as precise as possible during this step to ensure even cooking and melting of the cheese later on.

After cutting the curd into pieces, continue stirring for about 20 minutes. This step is crucial as it allows the curd to release whey and firm up before the final heating. The stirring action helps the curd develop a stronger structure, which will impact the final texture of the cheese.

The next step is to slowly increase the heat to 102°F (39°C) to begin drying out the curds. This is done by first removing a portion of the whey and then slowly adding back warm water over 20 to 30 minutes. Start by removing about 30% of the whey and stirring the curds well. This step reduces lactose in the mixture and limits bacteria growth and acid production, resulting in a sweeter cheese.

Finally, add back a volume of warm water that is about half of what was removed. The water should be at approximately 140°F (60°C) and slowly added to the curds while continuously stirring. This step should also take about 20 to 30 minutes, and the final temperature should reach about 102°F (39°C). The curds are then held at this cook temperature for 30 to 45 minutes while being stirred continuously.

Hot Pockets: Real Cheese or Not?

You may want to see also

Explore related products

Draining and replacing whey

Draining the Whey:

First, use a balloon whisk to cut the curd into 0.75 cm (1/4 inch) cubes. Continue stirring for 20 minutes and then let the mixture stand for 5 minutes. Next, drain off the whey using a sieve and ladle to ensure only the whey is removed. This step exposes the curds, which are solid milk clumps formed when milk proteins coagulate.

Replacing with Warm Water:

Replace the drained whey with an equal amount of warm water (about 60°C or 140°F) to return to the original liquid level. This process increases the curd temperature to 38°C (100°F). Turn on low heat to gently warm the curds further to 42°C (108°F) over 30 minutes, stirring continuously. Ensure you stir slowly to keep the curds separate and moving.

Final Steps:

Let the curds settle and begin to mat together. Drain them into a cheesecloth-lined colander and allow them to drain for 1 minute. Then, bundle the curd-filled cheesecloth and transfer it to your cheese mould. Fold the cheesecloth over and place the follower on top. Finally, put the mould in the cheese press and press at 11 kg (24 lbs) for 30 minutes.

By following these steps, you will successfully drain and replace the whey during the Jarlsberg cheese-making process, contributing to the formation of its distinctive texture and flavour.

American Cheese: Where Is It Made?

You may want to see also

Pressing and moulding

Once the curds have been drained, the cheese is ready for pressing and moulding. The curds should be bundled up in the cheesecloth and transferred to the cheese mould. The cheesecloth should be folded over the curds, and the follower placed on top. The mould should then be placed in the cheese press and pressed at 11 kg (24 lbs) for 30 minutes.

After pressing, the cheese should be placed in a cool spot (10°C) for two weeks. This will help the proteins break down and provide a good texture for the "eyes" to develop during the subsequent four to six weeks at room temperature. The cheese should be left to age for a minimum of three months, though some variations are aged for nine, 12, or 15 months.

During the ageing process, the cheese should be stored at room temperature, ideally between 20°C and 25°C. If the temperature drops below 20°C, it is recommended to cover the cheese with a towel overnight.

Fast Food Cheese: What's Really in It?

You may want to see also

Frequently asked questions

Jarlsberg is a mild, semi-soft cow’s milk cheese of Norwegian origin. It is a Swiss-type cheese with a buttery, nutty flavour.

The exact process is a trade secret, but it involves heating milk to around 33-37°C, adding bacterial culture, cutting the curd, draining off the whey, and pressing the curds into a mould. The cheese is then aged for a minimum of three months.

The cheese was developed in the 1950s by Professor Ole Martin Ystgaard of the Dairy Institute at the Agricultural University of Norway. It was based on an earlier version of the cheese produced in the early 1800s and is named after a Norwegian nobleman, Count Wedel Jarlsberg.

The exact recipe is a closely guarded secret, but it involves the use of protected cultures and bacterial culture owned by the manufacturer.

Jarlsberg cheese is produced in Norway, Ireland, and the US state of Ohio. It is available in many countries, including the United States, the United Kingdom, Australia, and Canada.

![Artisan Cheese Making at Home: Techniques & Recipes for Mastering World-Class Cheeses [A Cookbook]](https://m.media-amazon.com/images/I/81eH1+cYeZL._AC_UL320_.jpg)