Parmesan cheese is a family of hard grating cheeses made from cow's milk. In the United States, the Code of Federal Regulations includes a Standard of Identity for Parmesan and Reggiano cheese, which defines the production process and the final result. This definition includes specifications such as the use of cow's milk, a curing period of at least 10 months, a maximum water content of 32%minimum of 32% milkfat in solids. Many Wisconsin cheesemakers, some founded by Italian immigrants, produce Parmesan in whole wheels, while generic American Parmesan is often sold pre-grated and has been aged for less than 12 months.

Explore related products

What You'll Learn

Ingredients: Parmesan is made from cow's milk

Parmesan cheese, or Parmigiano Reggiano, is traditionally made from unpasteurised cow's milk. The milk from the morning milking is mixed with the naturally skimmed milk from the previous evening, creating a part-skimmed mixture. This mixture is then pumped into copper-lined vats, which heat the mixture evenly and contribute copper ions.

In the United States, the Code of Federal Regulations includes a Standard of Identity for "Parmesan and Reggiano cheese", which defines the production process and the final result. According to this standard, Parmesan must be made from cow's milk, cured for at least 10 months, and contain no more than 32% water and no less than 32% milk fat.

Outside of the European Union, the name "Parmesan" is used for a family of hard grating cheeses inspired by the original Italian cheese. These imitation cheeses are also made from cow's milk and are generally pale yellow in colour. They are often sold already grated and have been aged for less than 12 months.

In the US, several manufacturers have been investigated for allegedly exceeding the 4% cellulose limit allowed in grated cheese. In one case, a Pennsylvania manufacturer was found to be producing grated "Parmesan" without any actual Parmesan cheese, instead using a mixture of other cheeses and cellulose.

The Art of Making Yellow Cheese: A Guide

You may want to see also

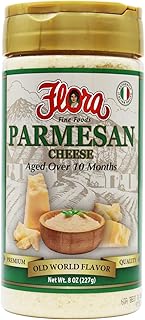

Curing: It must be cured for at least 10 months

Curing is a critical step in the production of Parmesan cheese, and in the United States, the Code of Federal Regulations mandates that Parmesan must be cured for at least 10 months. This extended curing period is essential for developing the cheese's distinctive sharp and complex flavour, as well as its hard, dry texture.

During the curing process, the cheese wheels are typically stored in temperature- and humidity-controlled environments. The ideal temperature range for curing Parmesan cheese is between 15°C to 18°C (59°F to 64°F), with relative humidity levels maintained around 75-80%. These conditions allow the cheese to age slowly and consistently, promoting the development of the desired texture and flavour characteristics.

The curing rooms are carefully designed to facilitate air circulation and maintain the optimal temperature and humidity levels. Regular rotations of the cheese wheels are conducted to ensure even curing and prevent the formation of moisture pockets or mould. Skilled cheesemakers monitor the curing process closely, checking for any signs of imperfection and making adjustments as necessary to ensure the highest quality.

The lengthy curing period also allows the cheese to develop its characteristic crystalline structure. Over time, amino acids in the cheese form flavour-enhancing crystals, contributing to the unique mouthfeel and texture of well-aged Parmesan. This process is crucial in transforming the cheese from a soft, pliable state after pressing to the hard, granular texture that is sought after in grated Parmesan.

While the minimum curing duration is set at 10 months, many cheesemakers choose to age their Parmesan for longer periods. Extended curing can enhance the cheese's flavour and texture further, making it even more flavourful and granular. However, this also increases the production cost and time-to-market, which are important considerations for commercial cheesemakers.

Great Value Cheese: Where Is It Made?

You may want to see also

Moisture: No more than 32% water

In the United States, the Code of Federal Regulations includes a Standard of Identity for "Parmesan and Reggiano cheese". This standard defines the production process and the final result. Parmesan must be made from cow's milk, cured for at least 10 months, and contain no more than 32% water. This moisture limit is crucial to the cheese's classification as it helps define the cheese's texture and hardness. Parmesan is known for its hard, sharp and dry texture, and this moisture limit ensures that the cheese meets these expectations.

The moisture content in Parmesan cheese is carefully controlled during the cheese-making process. The first step in achieving the desired moisture level is to use the right type of milk. Parmesan is traditionally made from raw or unpasteurised cow's milk. The whole milk from the morning milking is mixed with the naturally skimmed milk from the previous evening, resulting in a part-skim mixture. This mixture has a lower fat and water content than whole milk, which helps reduce the overall moisture in the final cheese.

The milk mixture is then pumped into copper-lined vats, which heat evenly and contribute copper ions to the mix. The heating process helps to reduce the moisture content further by evaporating some of the water. After heating, the milk mixture is typically treated with rennet, a coagulating agent that helps separate the milk into curds and whey. The curds are then cut and stirred, and some of the whey is removed, which also helps lower the overall moisture content.

The curds are then pressed to remove more whey and form the cheese into wheels. The pressing step is crucial in reducing the moisture content and creating a firm, dry texture. Finally, the cheese wheels are cured or aged for at least 10 months. During this ageing process, the cheese loses additional moisture through evaporation and the development of a natural rind. This rind helps protect the cheese from excess moisture absorption and contributes to its final texture.

Some American manufacturers have been investigated for allegedly exceeding the permitted moisture limit in their "Parmesan" cheese products. These cases highlight the importance of adhering to the defined standards for Parmesan cheese production and the potential consequences of deviating from them. Overall, the moisture limit of no more than 32% water is a critical factor in defining the quality and characteristics of authentic Parmesan cheese.

Brie Cheese Coating: What's the White Stuff?

You may want to see also

Explore related products

Milkfat: Solids must contain at least 32% milkfat

In the United States, the Code of Federal Regulations includes a "Standard of Identity" for Parmesan and Reggiano cheese. This standard defines the production process and the final result. Parmesan must be made from cow's milk, cured for at least 10 months, contain no more than 32% water, and have at least 32% milkfat in its solids. This requirement of a minimum of 32% milkfat in the solids distinguishes the American Parmesan from its European counterpart, Parmigiano Reggiano, which is protected by law within the European Union.

The milkfat percentage in the solids is a critical factor in determining the quality and characteristics of the cheese. Milkfat, also known as butterfat, is a key component in cheese-making as it contributes to the flavour, texture, and melting properties of the final product. The higher the milkfat content, the richer and creamier the cheese will taste. In the context of Parmesan cheese, the requirement of at least 32% milkfat in the solids ensures that the cheese has the desired flavour, texture, and functional properties.

To achieve this minimum milkfat percentage, cheesemakers in the United States may employ various techniques. One common method is to use a specific blend of milk, such as combining the whole milk of the morning milking with the naturally skimmed milk of the previous evening's milking, as is traditionally done for Parmigiano Reggiano. This results in a part-skim mixture that helps achieve the desired milkfat content. Additionally, the milk may undergo further processing, such as standardisation, to ensure a consistent milkfat percentage across batches.

The milkfat content is carefully monitored and controlled throughout the cheese-making process. Cheesemakers utilise specialised equipment to measure and analyse the milkfat percentage at various stages, making adjustments as necessary to ensure compliance with the standard of identity. This attention to detail and precision in milkfat content contributes to the overall quality and consistency of the final product.

While the minimum milkfat requirement is a defining characteristic of American Parmesan cheese, it is essential to note that the curing process, moisture content, and other production aspects also play a significant role in crafting this popular cheese variety. The combination of these factors results in the unique characteristics that differentiate American Parmesan from its European counterparts and cater to the preferences and requirements of consumers in the United States and beyond.

Mozzarella Cheese: Step-by-Step Guide to Making It

You may want to see also

Anticaking agents: Grated cheese may contain up to 4% cellulose

Grated cheese is a convenient option for consumers, as it saves them the time and effort of having to grate a block of cheese themselves. However, this convenience comes at a cost: the addition of anti-caking agents like cellulose.

Cellulose is a derivative of wood pulp or plant fibres used to prevent shredded or grated cheese from clumping together in the package. It does this by absorbing the moisture out of the cheese, helping it to last longer. This is beneficial for grocery stores and consumers as it extends the shelf life of the product. However, it can negatively impact the cooking or melting of the cheese, resulting in a gritty texture instead of the desired creaminess.

In the United States, federal law allows for the addition of anti-caking agents to grated cheese, and it has been approved by the FDA for food use. Grated cheese may contain up to 4% cellulose as an anti-caking agent, according to 21 CFR 133.146. However, some manufacturers have been investigated for exceeding this limit. In one case, a Pennsylvania manufacturer was found guilty of selling a product labelled as "Parmesan" that contained no actual Parmesan cheese, only a mixture of other cheeses and cellulose.

The use of cellulose in grated cheese has been the subject of controversy and legal battles. Consumers have filed class-action lawsuits against cheesemakers and grocers, accusing them of false advertising when their products claimed to be 100% grated Parmesan cheese but contained non-cheese ingredients. While federal law allows for the inclusion of these ingredients, the front-label claims have been deemed deceptive and in violation of false advertising laws.

When it comes to Parmesan cheese specifically, the term "Parmesan" has different definitions depending on the region. Within the European Union, the term Parmesan is legally protected and can only be used to refer to Parmigiano Reggiano, which is produced in a restricted geographic area using specific methods. Outside of the EU, the name Parmesan is often used as a generic term for a family of hard grating cheeses made from cow's milk. In the US, the Code of Federal Regulations includes a Standard of Identity for "Parmesan and Reggiano cheese", defining the production process and final result.

Menonita Cheese: Crafting the Unique Flavor Experience

You may want to see also

Frequently asked questions

Parmesan cheese is made from cow's milk.

In the US, the Code of Federal Regulations includes a Standard of Identity for "Parmesan and Reggiano cheese", which defines the production process and the final result. This includes that Parmesan must be made from cow's milk, cured for 10 months or more, contain no more than 32% water, and have no less than 32% milk fat in its solids.

In the US, the term Parmesan is used for imitations of the original Italian Parmesan, which is more precisely called Parmigiano-Reggiano. The original Parmesan is made only in Italy, in specific provinces, and is protected by Italian and European law.