Washed-rind or smear-ripened cheeses are periodically treated with brine or mold-bearing agents to encourage the growth of certain bacteria on their surface, giving them distinctive flavours and smells. The process of washing cheese rinds started in France, where sixteenth-century monks made cheeses in their monasteries as a way to feed themselves. The conditions in monastery cellars were ideal for cheese bacteria, but to avoid the development of bad rinds, the monks washed the rinds with beer or brandy. This style of rind washing created softer, creamier cheeses, such as Epoisses de Bourgogne. Today, washed-rind cheeses can be soft, semi-hard, or hard, and are known for their pungent odours and distinctive flavours.

Explore related products

What You'll Learn

How to identify washed-rind cheese

Washed-rind cheeses are identified by their distinctive orange or red rind, which is moist, sticky, and often smelly. The rind is usually a result of the cheese being washed or cured in a solution of saltwater brine, which discourages the growth of certain moulds and bacteria, while encouraging the growth of others, such as brevibacterium linens. The greater the frequency of washing, the more oozy, sticky, and smellier the cheese will be.

The smell of washed-rind cheeses is often likened to that of a farmyard or sweaty feet, with pungent aromas and intense savoury flavours. The texture of the cheese can vary from creamy and oozy to hard and grate-able. Soft washed-rind cheeses should be plump and moist, while hard washed-rind cheeses will have an orange-brown crust on the outside, which is not recommended for eating.

Some well-known examples of washed-rind cheeses include Taleggio, Langres, Vacherin Mont d’Or, and Gruyère. The UK's washed-rind scene is also growing, with cheeses such as Rollright and Stinking Bishop gaining recognition.

Washed-rind cheeses can be identified by their distinctive rinds and strong aromas. The texture and flavour of the cheese can vary depending on the frequency of washing and the moisture content.

Soft Cheeses Made From Raw Milk: A Guide

You may want to see also

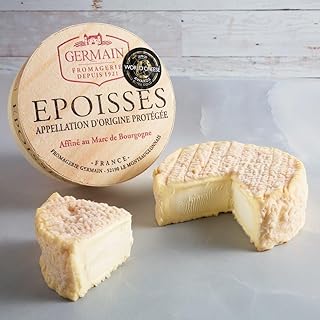

The history of washed-rind cheese

The process of making washed-rind cheese is believed to have originated in France during the 16th century, when monks in monasteries began making cheese to feed themselves. The conditions in the monastery cellars were ideal for cheese bacteria, but the uncontrolled environment often led to the development of bad rinds. To address this issue, the monks started washing the rinds with readily available liquids such as beer or brandy. This washing process created softer and creamier cheeses, with Epoisse de Bourgogne being one of the earliest and most renowned examples.

Around the same time, a similar practice emerged in mountainous regions, where high humidity made it challenging to control the growth of cheese bacteria. Cheesemakers in these areas opted to wash the rinds with brine due to the abundance of drinkable water in the mountains. This method of rind washing resulted in the creation of harder cheeses, with Gruyère being a well-known example.

The UK also has a rich history of washed-rind cheese production, with Stinking Bishop from Gloucestershire being one of the most famous varieties. This cheese gets its name from the Stinking Bishop pears used to make the perry that the cheese is washed in, rather than its smell. It is produced at Hunts Court Farm, which was once home to Cistercian monks, and the traditional methods of cheese-making have been preserved over the centuries.

The process of making washed-rind cheese has evolved and spread globally, with countries like the UK and the US now offering their own unique varieties. Washed-rind cheeses are known for their distinctive flavours, textures, and aromas, making them a beloved and sought-after delicacy worldwide.

Real Cheese: What Does It Actually Mean?

You may want to see also

The process of making washed-rind cheese

Washed-rind or smear-ripened cheeses are periodically treated with brine or mold-bearing agents. This process encourages the growth of certain bacteria on the surface of the cheese, giving it a distinctive flavour and texture. The term "washed rind" is used to describe any cheese with a brine-washed or moistened rind.

To make washed-rind cheese, cheesemakers first form and shape the cheese in a similar way to soft-ripened cheeses like Camembert or Brie. However, during the maturation process, the cheese is regularly washed with a brine solution or a salty water. This process can be done using a paper cloth, a cheesecloth, or a soft brush, depending on the robustness of the rind. The frequency of washing can vary from every two or three days to twice a week, and the process typically lasts for a month or so.

The brine solution can also include alcohol like beer, wine, or brandy, which contributes to the flavour and depth of the cheese. The washing process creates an environment that fosters the growth of bacteria, particularly Brevibacterium linens, which is responsible for the unique characteristics of washed-rind cheeses. This bacteria can also be added directly to the milk before cheesemaking or introduced after the cheese is removed from the mould.

The rate of ripening for washed-rind cheeses depends on various factors such as size, moisture content, temperature, and relative humidity. The high moisture content in washed-rind cheeses is achieved by cutting the curd into large pieces, cooking it at low temperatures of less than 35°C, and lightly pressing it. The washing process inhibits the growth of undesirable moulds and allows Brevibacterium linens to thrive, resulting in the characteristic reddish-orange hue and pungent aroma of washed-rind cheeses.

Dairy-Free Delights: Exploring Non-Dairy Cheeses and Their Flavors

You may want to see also

Explore related products

Different types of washed-rind cheese

Washed-rind cheese is a broad category of cheese with a distinctive sticky or moist exterior, a reddish-orange rind, and a pungent aroma. The process of making washed-rind cheese involves periodically washing the cheese with brine or mould-bearing agents, which encourages the growth of certain bacteria that give the cheese its unique flavour and texture. This process can result in both hard and soft cheeses. Here are some examples of different types of washed-rind cheese:

Soft Washed-Rind Cheese

- Limburger is a soft, washed-rind cheese with a pungent odour and distinctive flavour.

- Epoisses de Bourgogne is a famous French soft, washed-rind cheese known for its intense savouriness and strong aroma. It is washed with brandy-infused brine.

- Stinking Bishop is a soft washed-rind cheese made in Gloucestershire, UK. Despite its name, its aroma is derived from the Stinking Bishop pears used to make the perry that the cheese is washed in.

- Rollright is a French/Swiss-style washed-rind cheese made by King Stone Dairy in Oxfordshire, UK. It has a creamy, mellow interior and is wrapped in a band of spruce.

- Taleggio is an Italian washed-rind cheese with a mild, yeasty flavour and a sticky texture.

- Reblochon is a French washed-rind cheese with a distinctive flavour and texture.

Hard Washed-Rind Cheese

- Appenzeller is a hard, aged washed-rind cheese.

- Gruyère is a perfect example of a hard washed-rind cheese. It originated in the Swiss Alps and is known for its firm and dry texture.

- Winnimere is a luxurious, seasonal washed-rind cheese made in northern Vermont. It has a wobbly panna cotta-like interior encased in a layer of spruce bark, balancing intense savouriness with a Christmas-y aroma.

Mozzarella Cheese: Mastering the Art of Stretchy, Milky Curds

You may want to see also

How to serve washed-rind cheese

Washed-rind cheeses are almost universally smelly, with an intense aroma of farmyard animals and sweaty feet. They are also made in a very specific way—they are washed with a brine solution or alcohol like beer, wine, or brandy. This process makes the rind of the cheese more susceptible to bacteria, which give the cheese its distinctive orange-red hue.

When serving washed-rind cheese, it is important to consider the type of cheese, its texture, and its flavour. Soft washed-rind cheese should be plump and moist, with a reddish-orange rind. Avoid pieces that are brown or cracking. Hard washed-rind cheeses will have an orange-brown crust on the outside, which is not recommended for eating.

For serving suggestions, washed-rind cheeses can be paired with floral, honeyed, or fruity beverages like Riesling or Belgian ale. If serving a soft washed-rind cheese, provide bread or crackers to spread the cheese on. Hard washed-rind cheeses can be grated and used as a topping on dishes like pasta or salad.

Additionally, consider the origin of the washed-rind cheese when serving. For example, Epoisses de Bourgogne, a washed-rind cheese from France's Burgundy region, is packaged in a wooden box and should be scooped and smeared like butter. Meanwhile, the UK's Stinking Bishop, a soft washed-rind cheese made in Gloucestershire, uses the local Stinking Bishop pears to make the perry that the cheese is washed in.

The Art of Making Athenos Feta Cheese

You may want to see also

Frequently asked questions

Washed rind cheese is any cheese with a brine-washed (or moistened) rind.

The process of making washed rind cheese involves washing the cheese with brine or a salty water to prevent the growth of mould and bacteria on the rind. This creates an environment for bacteria like Brevibacterium linens to thrive, giving the cheese its distinctive orange-red hue, pungent smell, and flavour.

Some examples of washed rind cheese include Taleggio, Langres, Vacherin Mont d'Or, Gruyère, and Stinking Bishop.

Soft-ripened cheeses like Camembert or Brie are shaped and then matured, during which a white mould grows on the rind. Washed-rind cheeses are formed and shaped similarly but are washed with brine or alcohol during maturation, resulting in a different type of bacteria and rind.

Washed rind cheese has a distinctive flavour and aroma due to the bacteria that develop during the washing process. This process also helps prevent undesirable mould from forming on the cheese.