Cheese wire, a specialized tool designed for slicing through cheese with precision, is typically very thin to ensure clean cuts without crumbling the cheese. Its thickness generally ranges from 0.2 to 0.5 millimeters, depending on the manufacturer and intended use. This fine gauge allows the wire to glide effortlessly through both soft and hard cheeses, minimizing friction and maintaining the integrity of the cheese’s texture. While the exact thickness may vary slightly, the primary goal remains consistent: to provide a reliable and efficient cutting solution for cheese enthusiasts and professionals alike.

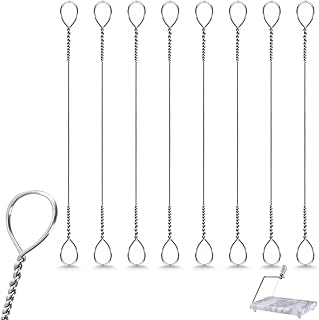

Explore related products

What You'll Learn

- Cheese Wire Gauge Standards: Industry standards for cheese wire thickness vary by region and application

- Material Composition: Stainless steel is common; affects durability and cutting efficiency

- Thickness Measurement: Typically measured in millimeters or gauge numbers for precision

- Impact on Cutting: Thicker wires are stronger but may require more force

- Maintenance Tips: Regular cleaning and storage prevent rust and ensure longevity

Cheese Wire Gauge Standards: Industry standards for cheese wire thickness vary by region and application

Cheese wire thickness is not a one-size-fits-all measurement. Industry standards dictate specific gauges based on regional preferences and intended use, ensuring optimal performance and safety in cheese cutting. For instance, European standards often lean towards thinner wires (around 0.35–0.4 mm) for softer cheeses like Brie or Camembert, allowing for clean cuts without excessive drag. In contrast, American standards may favor slightly thicker wires (0.45–0.5 mm) for harder varieties such as Cheddar or Parmesan, prioritizing durability and resistance to breakage.

Understanding these regional variations is crucial for manufacturers and consumers alike. A wire too thin for a hard cheese risks snapping mid-cut, while one too thick for a soft cheese can tear the texture. For example, in Switzerland, where semi-hard cheeses like Emmental are prevalent, wires typically range from 0.4 to 0.45 mm, striking a balance between flexibility and strength. This precision ensures the wire glides smoothly through the cheese, preserving its integrity and appearance.

When selecting cheese wire, consider the application. Commercial settings often require heavier-duty wires (up to 0.6 mm) to withstand frequent use and varied cheese types. Home users, however, may opt for thinner gauges (0.3–0.4 mm) tailored to the cheeses they most commonly consume. Always check the manufacturer’s recommendations, as some wires are designed for specific cheese categories or cutting techniques, such as straight slicing versus portioning.

Regional standards also reflect cultural cheese-cutting traditions. In France, where cheese is often served in thin, elegant slices, wires are typically finer to achieve precision. Conversely, in the UK, where chunkier portions are preferred, slightly thicker wires are more common. This interplay between function and culture highlights the importance of adhering to localized standards for the best results.

To ensure longevity and performance, maintain your cheese wire properly. Regularly inspect for fraying or weak spots, especially if using thicker gauges. Clean the wire after each use to prevent cheese residue buildup, which can dull the cutting edge. For thinner wires, handle with care to avoid bending or kinking. By aligning your choice of cheese wire with industry standards and application needs, you’ll achieve cleaner cuts and extend the tool’s lifespan, making every slice a testament to precision and craftsmanship.

Cheese Addiction: Can You Really Say 'I Could Never Give Up Cheese'?

You may want to see also

Material Composition: Stainless steel is common; affects durability and cutting efficiency

Stainless steel dominates the material composition of cheese wires, and for good reason. Its inherent properties make it an ideal candidate for this specific task. The chromium content in stainless steel, typically around 10.5%, forms a passive oxide layer on the surface, providing excellent corrosion resistance. This is crucial in a kitchen environment where exposure to moisture and acidic ingredients is common. Unlike wires made from standard steel, which can rust and degrade over time, stainless steel cheese wires maintain their integrity, ensuring a longer lifespan and consistent performance.

This durability directly translates to cutting efficiency. Stainless steel's hardness and tensile strength allow it to maintain a sharp edge, crucial for cleanly slicing through various cheese textures, from soft Brie to hard Parmesan. Softer materials might deform under pressure, leading to jagged cuts and wasted cheese.

While stainless steel reigns supreme, it's not the only player in the cheese wire material game. Some manufacturers offer wires made from other materials like nylon-coated steel or even plastic-coated options. These alternatives often prioritize flexibility over sheer cutting power, making them suitable for softer cheeses where a gentler touch is required. However, they may not withstand the rigors of cutting harder cheeses and are more prone to wear and tear over time.

When choosing a cheese wire, consider the types of cheese you frequently cut. For a versatile option that handles both soft and hard varieties, stainless steel is the clear winner. If you primarily work with softer cheeses and prioritize flexibility, explore alternative materials, keeping in mind their limitations in terms of durability and cutting efficiency.

Ultimately, the material composition of your cheese wire directly impacts its performance and longevity. Stainless steel, with its corrosion resistance and cutting prowess, stands as the most reliable choice for most cheese enthusiasts. Understanding the strengths and weaknesses of different materials empowers you to make an informed decision, ensuring you have the right tool for the job and perfectly sliced cheese every time.

Delicious Dips for Brazilian Cheese Bread: Elevate Your Snack Game

You may want to see also

Thickness Measurement: Typically measured in millimeters or gauge numbers for precision

Cheese wire thickness is a critical factor in its functionality, whether for slicing soft brie or cutting through aged cheddar. Precision in measurement ensures consistency and safety, preventing wire breakage or uneven cuts. Thickness is typically quantified in millimeters (mm) or gauge numbers, each system offering distinct advantages depending on the application.

Millimeter measurements provide a direct, linear understanding of the wire's diameter, making it intuitive for those accustomed to the metric system. For instance, a standard cheese wire might range from 0.3 mm to 0.7 mm, with thinner wires suited for delicate cheeses and thicker ones for harder varieties. Gauge numbers, on the other hand, operate inversely: a higher gauge indicates a thinner wire. This system is more common in specialized tools and may require a conversion chart for those unfamiliar with it.

To measure cheese wire thickness accurately, start by selecting the appropriate tool. Digital calipers offer precision down to 0.01 mm, ideal for professional settings or enthusiasts seeking exact measurements. For casual users, a simple ruler or gauge tool can suffice, though results may be less precise. When measuring, ensure the wire is taut and free of kinks, as these can skew readings. Record measurements in both millimeters and gauge numbers if possible, to accommodate different reference systems.

The choice between millimeters and gauge numbers often boils down to context. Millimeters are universally understood and align with most international standards, making them a safe bet for global applications. Gauge numbers, however, are deeply rooted in industries like manufacturing and craftsmanship, where tradition and specificity reign. For cheese wires, understanding both systems allows for flexibility, especially when sourcing tools from different regions or industries.

Practical tips for working with cheese wire thickness include matching the wire to the cheese type. Soft cheeses like camembert require thinner wires (around 0.3 mm) to avoid tearing, while hard cheeses like parmesan benefit from thicker wires (up to 0.7 mm) for clean cuts. Regularly inspect wires for wear and tear, as thinning or fraying can compromise performance. Finally, store wires properly—coiled rather than bent—to maintain their integrity and ensure longevity.

In conclusion, mastering cheese wire thickness measurement enhances both precision and efficiency in cheese cutting. Whether using millimeters or gauge numbers, the key lies in understanding the context and applying the right tools. By adopting these practices, users can achieve consistent results, elevating their cheese preparation to a professional standard.

What's in a Cheese Steak with Everything? A Philly Classic Explained

You may want to see also

Explore related products

Impact on Cutting: Thicker wires are stronger but may require more force

Cheese wire thickness directly influences its cutting performance, creating a balance between strength and ease of use. Thicker wires, typically ranging from 0.5 to 1.0 millimeters in diameter, offer greater durability and resistance to breaking under pressure. This makes them ideal for cutting hard, aged cheeses like Parmesan or Gouda, where thinner wires might snap under the strain. However, this added strength comes at a cost: thicker wires require more force to slice through cheese, which can be a drawback for softer varieties or for users with limited hand strength.

Consider the mechanics of cutting. A thicker wire has a larger cross-sectional area, increasing its resistance to bending and deformation. This rigidity allows it to maintain a straight cutting edge, reducing the likelihood of wobbling or fraying during use. For example, a 0.8 mm wire can handle the dense texture of a mature Cheddar with ease, whereas a 0.3 mm wire might struggle and bend, leading to uneven cuts. However, when slicing a soft Brie or Camembert, the increased force needed for a thicker wire can compress the cheese, altering its texture and presentation.

From a practical standpoint, selecting the right wire thickness depends on the cheese type and the user’s cutting technique. For hard cheeses, a thicker wire (0.7–1.0 mm) is recommended to ensure clean, precise cuts without the risk of breakage. For semi-soft or soft cheeses, a thinner wire (0.3–0.5 mm) is more suitable, as it requires less force and minimizes damage to the cheese’s structure. Users should also consider their own strength and comfort; those with arthritis or hand fatigue may find thicker wires more challenging to operate, even with ergonomic handles.

To optimize cutting efficiency, pair wire thickness with appropriate handling techniques. When using a thicker wire, apply steady, even pressure rather than abrupt force to avoid snapping the wire or crushing the cheese. For softer cheeses, a gentle sawing motion with a thinner wire can yield better results. Regularly inspect the wire for signs of wear, as even thicker wires can weaken over time, especially when cutting hard cheeses. Replacing the wire every 6–12 months ensures consistent performance and safety.

In summary, while thicker cheese wires offer superior strength and reliability for hard cheeses, they demand more force and may not be suitable for softer varieties. By matching wire thickness to cheese type and adjusting cutting techniques accordingly, users can achieve optimal results. This nuanced approach ensures both efficiency and precision, making cheese cutting a seamless task regardless of the cheese’s texture or the user’s capabilities.

Cheesecloth Method: Perfectly Warming Up Your Turkey Every Time

You may want to see also

Maintenance Tips: Regular cleaning and storage prevent rust and ensure longevity

Cheese wire, typically made of stainless steel, is a kitchen tool designed for precision slicing, but its longevity hinges on proper care. Rust, the arch-nemesis of metal tools, can compromise both functionality and hygiene. Regular cleaning and mindful storage are the twin pillars of maintenance, ensuring your cheese wire remains a reliable companion for years.

Stainless steel, while resistant to corrosion, isn't impervious. Cheese residue, especially from aged or oily varieties, can trap moisture, creating a breeding ground for rust. After each use, a simple yet thorough cleaning routine is essential. Dismantle the wire if possible, allowing access to all surfaces. Wash with warm, soapy water, using a soft brush to dislodge any clinging particles. Rinse meticulously, ensuring no soap residue remains, as this can also accelerate corrosion.

Drying is equally crucial. Air drying is ideal, but for expedited results, pat the wire dry with a clean cloth. Avoid dishwashers, as the harsh detergents and high temperatures can damage the wire's finish and potentially weaken its structure.

Storage plays a pivotal role in rust prevention. Moisture is the enemy, so choose a dry, well-ventilated area. Hanging the cheese wire allows air circulation, preventing moisture buildup. Consider storing it in a designated drawer lined with a silica gel packet to absorb any ambient humidity. For added protection, lightly coat the wire with food-grade mineral oil before storage. This creates a barrier against moisture and helps maintain the wire's flexibility.

Remember, consistency is key. Incorporate cleaning and proper storage into your post-cheese-cutting routine. By investing a few minutes in care, you'll safeguard your cheese wire, ensuring it delivers clean, precise slices for countless cheese boards to come.

Mastering Seed Separation: Draining Smoothie Seeds with Cheesecloth

You may want to see also

Frequently asked questions

A standard cheese wire is typically around 0.3 to 0.5 millimeters (0.012 to 0.020 inches) in thickness.

Yes, the thickness of cheese wire can vary slightly by brand, but most fall within the standard range of 0.3 to 0.5 millimeters.

Not necessarily. Thicker cheese wire may be more durable but can be less flexible, making it harder to cut through hard cheeses smoothly. Standard thickness is usually sufficient.

Yes, thicker cheese wire tends to be more durable and less prone to breaking, but it may sacrifice some flexibility compared to thinner options.