Building a cold smoker for cheese is a rewarding project that allows you to infuse your favorite cheeses with rich, smoky flavors without exposing them to heat that could cause melting. Cold smoking operates at temperatures below 90°F (32°C), ensuring the cheese remains intact while absorbing the smoke. To start, you’ll need a smoker box or cabinet, a smoke generator (such as a pellet smoker or smoke tube), and a way to maintain low temperatures, often achieved by placing the smoke source away from the cheese chamber. Proper ventilation and airtight seals are crucial to control smoke flow and prevent heat buildup. With the right materials and techniques, you can create a DIY cold smoker tailored to your needs, opening up a world of gourmet cheese crafting possibilities.

| Characteristics | Values |

|---|---|

| Smoker Type | Cold smoker (maintains temperatures below 90°F/32°C to prevent cheese melting) |

| Materials Needed | - Metal container (e.g., old filing cabinet, ammo box, or purpose-built smoker) - Electric hot plate or propane burner - Smoke generator (e.g., pellet tube, maze smoker, or smoke bomb) - Wood pellets or dust (e.g., hickory, apple, or mesquite) - Thermometer - Cheese racks or trays - Ventilation system (e.g., computer fan or natural draft) |

| Temperature Range | 60°F–90°F (15°C–32°C) |

| Smoke Duration | 1–6 hours, depending on desired smoke intensity |

| Cheese Preparation | Chill cheese to 35°F–40°F (2°C–4°C) before smoking |

| Smoke Flavor Options | Hickory, apple, mesquite, cherry, pecan, or custom blends |

| Ventilation Requirements | Proper airflow to maintain consistent smoke levels and temperature |

| Safety Considerations | Avoid overheating; use food-safe materials; monitor temperature closely |

| Cost Estimate | $50–$300 (depending on materials and design complexity) |

| Maintenance | Regular cleaning to prevent mold or residue buildup |

| Popular Designs | - Pellet tube smoker - Maze smoker - DIY filing cabinet smoker - Propane-powered cold smoker |

| Additional Tips | - Use a water pan to regulate humidity - Experiment with different wood types for unique flavors - Store smoked cheese in a cool, dry place for 1–2 weeks before consuming |

Explore related products

What You'll Learn

- Materials Needed: Essential tools, wood, and hardware required for constructing a cold smoker

- Design Basics: Simple, efficient designs for cold smoking cheese safely

- Temperature Control: Methods to maintain low temperatures for cheese smoking

- Assembly Steps: Step-by-step guide to building the smoker structure

- Safety Tips: Precautions to prevent overheating and ensure food safety

Materials Needed: Essential tools, wood, and hardware required for constructing a cold smoker

Building a cold smoker for cheese requires a blend of precision and practicality. The foundation lies in selecting the right materials, which can make or break your project. Start with a sturdy container for the smoke chamber—a metal trash can or a large food-grade plastic drum works well. Ensure it’s clean and free of chemicals that could taint the cheese. Pair this with a dedicated smoker box or tray for the wood chips, ideally made of stainless steel to prevent rust and ensure even smoke distribution. These two components form the core of your setup, dictating both durability and flavor consistency.

Tools are the unsung heroes of this endeavor. A drill with a variety of bits is essential for creating ventilation holes and mounting hardware. A jigsaw or angle grinder may be needed to cut metal or adjust the size of your chamber. For assembly, have a screwdriver, wrench, and pliers on hand to secure bolts, nuts, and clamps. Measuring tools like a tape measure and a level ensure accuracy, preventing leaks that could disrupt smoke flow. Investing in quality tools not only simplifies construction but also enhances the longevity of your smoker.

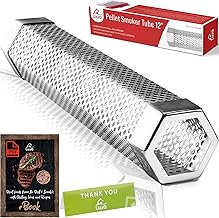

Wood selection is critical for achieving the desired flavor profile. Fruitwoods like apple or cherry impart a sweet, mild smoke ideal for cheeses, while hickory or mesquite can overpower delicate varieties. Opt for untreated, dry wood chips or pellets to avoid toxins. For cold smoking, where temperatures must stay below 90°F (32°C), a steady, controlled burn is key. Consider using a maze-style smoke generator or a pellet tube smoker to maintain consistent smoke output without heat spikes.

Hardware ties everything together, ensuring functionality and safety. A reliable thermometer is non-negotiable for monitoring chamber temperature, with digital probes offering the most accuracy. Hinges and latches secure the lid, while adjustable vents control airflow. Food-safe silicone seals or high-temperature gasket material prevent smoke leaks. If incorporating a smoke generator, ensure it’s compatible with your chamber size and has a long burn time. Every piece of hardware should be chosen with the dual goals of efficiency and food safety in mind.

Finally, don’t overlook the importance of accessories that elevate your setup. A wire rack or grate inside the chamber allows air to circulate around the cheese, promoting even smoking. A water pan can help regulate humidity, preventing the cheese from drying out. For added convenience, consider a remote thermometer or a smartphone-connected monitor to track conditions without opening the smoker. These extras, while not mandatory, transform a basic smoker into a professional-grade tool tailored to the art of cold-smoking cheese.

Should Aged Gouda Be Refrigerated? Storage Tips for Optimal Flavor

You may want to see also

Design Basics: Simple, efficient designs for cold smoking cheese safely

Cold smoking cheese requires precise temperature control—ideally below 90°F (32°C)—to prevent melting or bacterial growth. A simple, efficient design hinges on separating the smoke source from the cheese chamber, ensuring smoke flows without heat transfer. Start with a two-chamber system: one for generating smoke (using a smoker box or pellet tube) and another for holding the cheese. Connect them with a long, insulated pipe to allow smoke to travel while keeping heat at bay. This setup mimics professional cold smokers but at a fraction of the cost, using materials like metal drums, wooden boxes, or even repurposed coolers.

Analyzing common designs reveals a recurring theme: airflow management is critical. A dedicated fan or natural draft system ensures consistent smoke circulation without overheating. For instance, a 12V computer fan paired with a thermostat controller can regulate airflow, maintaining temperatures within the safe zone. Position the fan at the bottom of the cheese chamber to create a gentle updraft, preventing smoke stagnation. Alternatively, a passive design using a tall chimney effect can work if the smoke source is lower than the cheese chamber, though this requires careful calibration to avoid temperature spikes.

Safety is non-negotiable when cold smoking cheese. Always use food-grade materials for the cheese chamber and avoid plastics that can leach chemicals under heat. Stainless steel or aluminum mesh trays are ideal for holding cheese, allowing smoke to envelop the product evenly. Monitor temperatures with a digital thermometer placed near the cheese, not the smoke source, to ensure accuracy. For added safety, keep the setup in a well-ventilated area and avoid flammable materials nearby, especially when using propane or wood-fired smoke generators.

A comparative look at DIY designs highlights the pellet tube smoker as a standout option. This device, often made from a metal pipe filled with wood pellets, smolders slowly when heated by a propane torch or hot plate. Connected to the cheese chamber via a flexible hose, it delivers a steady stream of smoke without heat. This method is more efficient than traditional chip pans, as pellets burn longer and produce consistent smoke. Pairing a pellet tube with a cooler-based cheese chamber creates a compact, portable system ideal for beginners.

In conclusion, simplicity and precision are the cornerstones of a successful cold smoker for cheese. By separating the smoke source, managing airflow, and prioritizing safety, even novice builders can create an effective setup. Start with a two-chamber design, incorporate a regulated airflow system, and use food-safe materials to ensure both quality and safety. Whether opting for a fan-assisted or passive design, the goal remains the same: cool, flavorful smoke that transforms cheese without compromising its texture or integrity.

How Cheese Digests: Understanding Its Breakdown in the Human Body

You may want to see also

Temperature Control: Methods to maintain low temperatures for cheese smoking

Maintaining precise low temperatures is critical for cold smoking cheese, as excessive heat can melt or alter its texture. The ideal range is 60°–90°F (15°–32°C), with most cheese varieties performing best around 70°–80°F (21°–27°C). Achieving this requires a combination of insulation, airflow management, and heat source control. For instance, using a pellet smoker with a dedicated cold smoke attachment allows for finer temperature regulation compared to traditional barrel smokers, which often struggle to stay below 100°F (38°C).

One effective method is the ice chest technique, where a cooler is repurposed as a smoke chamber. Place a pan of ice beneath the cheese grate and position the smoke generator (such as a maze smoker or smoke tube) outside the cooler. The ice absorbs ambient heat, stabilizing temperatures for up to 4 hours before replenishment is needed. This setup is cost-effective and portable, making it ideal for beginners or small-batch smoking. However, monitor humidity levels, as excessive moisture can soften the cheese’s rind.

For longer smoking sessions, consider a water bath system. Submerge the smoke chamber in a larger container filled with cold water, creating a thermal barrier that prevents heat buildup. This method is particularly useful in warmer climates, where ambient temperatures can spike unexpectedly. Pairing this with a digital thermometer and a remote temperature probe ensures real-time monitoring, allowing adjustments before temperatures exceed the safe zone.

Advanced smokers may opt for PID controllers, which automate temperature regulation by modulating the heat source. These devices, commonly used in DIY setups, connect to a heating element and adjust power output based on sensor readings. While more expensive, they offer unparalleled precision, maintaining temperatures within ±2°F (±1°C) of the target. This is especially valuable for aging cheeses like cheddar or gouda, which benefit from extended smoking times.

Lastly, strategic airflow management plays a pivotal role. Positioning vents to allow cool air intake while directing smoke flow prevents heat accumulation. For example, placing the smoke generator at ground level and angling the exhaust vent upward creates a natural convection current, drawing cooler air from below. Combining this with a shade cloth or reflective insulation around the smoker further mitigates external heat sources, ensuring consistent low temperatures throughout the smoking process.

Each method has its trade-offs—cost, complexity, and scalability—but all share the common goal of preserving cheese integrity through meticulous temperature control. Experimenting with these techniques will help identify the best fit for your setup, whether you’re a hobbyist or a small-scale producer.

Chuck E. Cheese's Business Model: Fun, Games, and No Gambling

You may want to see also

Explore related products

Assembly Steps: Step-by-step guide to building the smoker structure

Building a cold smoker for cheese requires precision and attention to detail to ensure consistent, low temperatures that preserve the cheese’s texture while infusing it with smoky flavor. Begin by selecting a food-safe container for the smoking chamber, such as a large plastic storage bin or a wooden crate lined with aluminum foil. Ensure it has a tight-fitting lid to contain smoke, but drill a small vent hole to prevent pressure buildup. This foundation sets the stage for a controlled smoking environment.

Next, construct the smoke generator, which is the heart of the system. A common method involves using a pellet smoker tube or a cast-iron skillet filled with wood chips. For DIY enthusiasts, a metal pipe with holes drilled along its length works well. Attach this to a small propane torch or a hot plate to smolder the wood chips without exceeding 90°F (32°C), the critical temperature threshold for cold smoking. Secure the smoke generator outside the smoking chamber, connecting it via a flexible metal dryer vent hose to direct smoke inside.

Assemble the smoking chamber by placing a wire rack or wooden slats inside the container to hold the cheese. Position the vent hose near the bottom to ensure smoke rises evenly. Use a thermometer to monitor internal temperature, placing it at cheese level for accuracy. If using a propane torch, regulate the flame to maintain low heat; for hot plates, set to the lowest setting and test with a thermometer to avoid overheating.

Finally, test the system before smoking cheese. Light the wood chips and observe smoke flow, ensuring it fills the chamber without escaping. Adjust the vent hole size or lid seal if needed. Once calibrated, the smoker is ready for use. Remember, cold smoking is a slow process—plan for 6–12 hours of smoke exposure, depending on desired flavor intensity. This structured approach guarantees a functional, safe, and effective cold smoker tailored for cheese.

Half a Pound of Cheese: Converting Ounces Made Simple

You may want to see also

Safety Tips: Precautions to prevent overheating and ensure food safety

Cold smoking cheese requires precise temperature control to prevent overheating, which can melt or spoil the cheese. The ideal temperature range is between 68°F and 86°F (20°C and 30°C). Exceeding this range risks altering the cheese’s texture and flavor. To monitor temperatures accurately, invest in a dual-probe thermometer—one probe for the smoking chamber and another for the cheese itself. This setup ensures you can detect and address temperature fluctuations before they cause damage.

Analyzing common overheating causes reveals that inadequate ventilation is a frequent culprit. Smoke needs to flow freely to maintain consistent temperatures. Design your smoker with adjustable vents or a dedicated exhaust system to regulate airflow. If using a DIY setup, such as a pellet smoker or a repurposed grill, ensure the smoke source is separated from the cheese by a water pan or barrier. This not only prevents direct heat transfer but also adds humidity, which is crucial for cold smoking.

A persuasive argument for safety lies in the use of food-grade materials. Avoid metals like galvanized steel or non-food-safe plastics, as they can release toxins when heated. Opt for stainless steel, aluminum, or cedar wood for your smoker’s construction. Additionally, clean all components thoroughly before use to eliminate contaminants. For the smoke source, choose hardwood chips or pellets free from resins or additives, as these can introduce harmful chemicals or off-flavors.

Comparing cold smoking to hot smoking highlights the importance of time management. Cold smoking sessions can last 1–6 hours, depending on the cheese variety and desired flavor intensity. However, prolonged exposure, even at low temperatures, can dry out the cheese. To mitigate this, limit smoking sessions to 2–3 hours and allow the cheese to rest in a cool, humid environment afterward. Wrapping the cheese in cheesecloth during smoking can also protect it from excessive drying.

Instructive steps for preventing overheating include regular maintenance of your smoker. Clean ash buildup and inspect the smoke generator for blockages before each use. If using a propane or electric smoker, ensure the heat source is calibrated correctly. For pellet smokers, avoid overfilling the hopper, as this can lead to uneven burning and temperature spikes. Finally, always keep a fire extinguisher nearby as a precautionary measure, especially when working with flammable materials like wood chips.

By implementing these precautions—monitoring temperatures, ensuring proper ventilation, using safe materials, managing time, and maintaining equipment—you can cold smoke cheese safely and effectively. These measures not only protect the cheese but also safeguard your health, ensuring a delicious and risk-free smoking experience.

Gloucestershire Cheese Roll: Navigating the Steep, Thrilling Descent

You may want to see also

Frequently asked questions

You’ll need a smoker box or container (like a wooden crate or metal container), a smoke generator (such as a pellet smoker tube or maze smoker), a rack for the cheese, and a way to maintain low temperatures (around 90°F or below), like a heat source with precise control or ambient temperature monitoring.

Use a smoke generator that produces smoke without heat, such as a pellet smoker tube or a maze smoker. Place the cheese in a cool environment, like a garage or shed, and monitor the temperature with a thermometer. Avoid direct heat sources that could melt the cheese.

Cold smoking cheese typically takes 1-6 hours, depending on the desired flavor intensity. Smoke the cheese in intervals (e.g., 1 hour on, 1 hour off) to prevent overheating. Let the cheese rest in the refrigerator for 1-2 weeks after smoking to allow the flavors to develop.

Yes, you can use various wood chips like hickory, apple, or mesquite, but milder woods like alder or cherry are often preferred for cheese. Use a small amount of chips (about 1/4 cup) in your smoke generator, as too much smoke can overpower the cheese’s flavor.