Camembert is a soft, creamy, and buttery French cheese with a beautiful white rind and a distinctive flavour. It is said to have been first made in 1791 by Marie Harel, a farmer from Normandy, France. The process of making Camembert is quite challenging and involves heating milk, adding cultures, cutting curds, moulding, salting, and ripening. The cheese is then wrapped in paper and sometimes placed in wooden boxes for transport. In this article, we will explore the fascinating history of Camembert, the intricate process of its creation, and the variations in its production around the world.

Explore related products

What You'll Learn

The history of Camembert

Camembert is a luscious, buttery, bloomy-rinded cow's milk cheese that is considered one of France's most iconic cheeses. It is native to Normandy, specifically the village of Camembert, with historical records dating the first mention of the cheese to the early 18th century.

According to legend, Camembert was invented in 1791 by Marie Harel, a farmer from Normandy. During the French Revolution, Harel is said to have refined an existing cheese recipe from the Pays d'Auge region with guidance from Abbot Charles-Jean Bonvoust from Alençon. She then passed on her knowledge to her daughter, whose husband, Victor Paynel, presented one of his wife's best cheeses to Napoleon III, who gave it his royal seal of approval.

The process of making Camembert involves culturing milk, which is typically raw and unpasteurized in the case of French Camembert, or pasteurized for the variety produced in the United States. The cheesemaker coagulates the cultured milk with rennet, forming a soft yet solid curd. The curd is then cut into small cubes, transferred into cylindrical molds, and drained. Afterward, the wheels of Camembert are salted and ripened, developing a white rind created by the bacteria Penicillium candidum. During this aging process, the cheese forms its distinctive creamy texture and stronger flavour.

In terms of taste and texture, Camembert has a stronger, slightly sour, and sometimes chalky flavour compared to similar cheeses like Brie. It is softer than Brie, and when warmed, it becomes creamier while retaining its shape. Camembert is typically ripened as a small, round cheese with a diameter of 10.2 cm (4 in) and a thickness of 3.2 cm (1.26 in), fully covered by its rind.

Over time, Camembert has become deeply ingrained in French popular culture. During World War I, it was issued to French troops, and today, it holds a protected designation of origin. Camembert has also gained international recognition, with local varieties produced worldwide, including in the United States, Hungary, the Czech Republic, and Slovakia.

The Making of Processed American Cheese

You may want to see also

The process of making Camembert

Camembert is a soft, creamy, and buttery French cheese with a bloomy rind and a distinctive flavour. It is one of the trickier cheeses to make, even for experienced cheese-makers. The process of making Camembert is a complex one, and the following is a step-by-step guide to crafting this iconic cheese.

Firstly, the milk is cultured and coagulated with rennet, forming a soft yet solid curd. The type of milk used varies; in the United States, Camembert is made with pasteurized milk, while in France, it is typically made with raw milk from Normandé cows. The curd is then cut into small cubes, roughly half an inch in size, and carefully transferred into cylindrical moulds. The moulds are then salted and left to drain, a crucial step to prevent the cheese from flattening.

After this, the cheese is ripened. The surface of each cheese is sprayed with an aqueous suspension of the mould Penicillium camemberti, and the cheeses are left to ripen for a minimum of three weeks. This process gives Camembert its distinctive white rind and creamy interior. The rind is formed by beneficial microbes, including bacteria, which slowly ripen the cheese from the outside in, breaking down the fats and proteins. As the cheese ages, a soft, liquid cream line forms beneath the rind, and the flavour intensifies.

Once the cheese is ripe, it is wrapped in paper and sometimes placed in wooden boxes for transport. The cheese is typically sold at about one month old but can be aged longer, depending on the desired flavour. It is important to note that the temperature during the ageing process greatly affects the flavour of the cheese. If the temperature is above 7°C, the cheese will have an overpowering flavour.

The Mystery Behind Blue Cheese: Animal Origins Explored

You may want to see also

The ingredients and tools required

To make Camembert cheese, you will need the following ingredients:

- Milk (either pasteurized or raw)

- Mesophilic starter culture

- Geotrichium candidum culture

- Calcium chloride (if using homogenized milk)

- Rennet

You will also need the following tools and equipment:

- A large pot

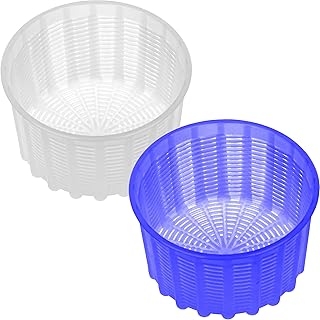

- Cheese hoops or moulds

- Cheese wrap or wax/parchment paper

- Plastic wrap

- Sterile knife

- Refrigerator

Additionally, you may want to use some of the following items for serving and storage:

- Thin, round wooden containers made from poplar

- Wooden boxes for transport

- Paper for wrapping

- Tin cans or cartons

- Cracker

- Fruit

- French bread

The Mystery of American Cheese: What's Inside?

You may want to see also

Explore related products

The differences between homemade and industrial Camembert

The process of making Camembert cheese at home is quite different from industrial production. The former is a delicate process that requires patience and precision, while the latter involves modern equipment and techniques to optimise production.

Homemade Camembert

Making Camembert at home involves several steps, each requiring careful attention to detail. First, milk is warmed to 90°F (32°C) in a pot of warm water or on a stove. Once the milk reaches the right temperature, bacterial culture and rennet are added to coagulate the milk. The curd is then cut into cubes, salted, and placed into moulds. These moulds need to be turned frequently to allow for even drainage, resulting in a flat, cylindrical cheese mass. The cheese is then sprayed with a mould, such as Penicillium camemberti, and left to ripen for at least three weeks. This process gives Camembert its distinctive rind and creamy texture.

Industrial Camembert

On the other hand, industrial Camembert production has been optimised for large-scale manufacturing. One method involves using continuous moulding and demoulding equipment, such as the 'Camatic' system. In this process, pasteurised milk is ultrafiltered at 50°C to create a pre-cheese mixture. This mixture is then cooled, and various ingredients are added, including a mesophilic lactic starter and NaCl. The mixture is then poured into moulds and incubated to allow for acidification and coagulation. After cooling, the cheese is cut into pieces and ripened.

Variations in Ingredients and Techniques

One notable difference between homemade and industrial Camembert is the type of milk used. Homemade Camembert can be made with either pasteurised or raw milk, depending on the cheesemaker's preference and local regulations. In contrast, industrial Camembert is typically made with pasteurised milk to comply with safety regulations and extend its shelf life.

The use of different equipment also leads to variations in the shape and size of the final product. Homemade Camembert is typically made in small, round moulds, resulting in a cheese that is fully covered by its rind. In contrast, industrial Camembert is often produced in larger wheels or rectangular trays, which affect the ripening process and the final texture of the cheese.

In summary, the differences between homemade and industrial Camembert lie in the scale of production, equipment used, and techniques employed. Homemade Camembert involves a more traditional, labour-intensive process, while industrial Camembert utilises modern technology to optimise production and standardise the final product.

The Magic of Parmigiano Cheese: Cow's Milk Transformation

You may want to see also

How to store and transport Camembert

Storing and transporting Camembert correctly is essential to maintaining its quality and shelf life. Here are some detailed instructions on how to do this:

Storing Camembert:

- Temperature and Humidity: Camembert requires proper temperature control and humidity to stay fresh. The ideal storage temperature is below 70 degrees Fahrenheit (21 degrees Celsius).

- Refrigerator Storage: When storing Camembert in the refrigerator, wrap it in cheese paper or a perforated plastic wrap to allow the cheese to breathe. Avoid using airtight containers or plastic wrap, as Camembert needs oxygen to prevent the formation of ammonia and excess moisture. Place the wrapped cheese in the coldest part of your refrigerator, such as the vegetable crisper.

- Counter Storage: If you prefer to store Camembert at room temperature, it can be kept on the counter for up to seven days. However, ensure it is stored below 70 degrees Fahrenheit.

- Cheese Grotto: Using a Cheese Grotto is an excellent option for storing Camembert. The reusable clay brick in the Grotto maintains the perfect humidity for the cheese, eliminating the need for cheese paper or plastic wrap.

- Original Packaging: If you purchase Camembert in a wooden box, you can leave it in the box and wrap it in the paper it comes with. This packaging helps maintain the ideal humidity and protects the cheese during storage.

- Ripening: If you want to ripen a young wheel of Camembert further, you can use the Cheese Grotto to achieve your desired aroma, flavour, and texture.

Transporting Camembert:

- Transporting Camembert safely requires similar considerations to storage. Ideally, transport Camembert in its original packaging, including the wooden box and paper wrapping, as this provides some protection and helps maintain humidity.

- Transporting in a Cooler: If you need to transport Camembert over long distances or in warm climates, use a cooler with ice packs to maintain a cool temperature. Place the wrapped Camembert in the cooler, ensuring it is secure and does not roll around during transport.

- Transporting in a Vehicle: When transporting Camembert in a vehicle, keep it in a stable, upright position to prevent damage or spoilage. Place it in a secure area of the vehicle, such as the floor behind the front seats, to minimise movement.

- Time Considerations: Try to minimise the time Camembert is left unrefrigerated during transport. The longer it is left at room temperature, the faster it will spoil, so plan your transport accordingly.

By following these instructions, you can ensure that your Camembert remains in optimal condition during storage and transport, preserving its distinctive flavour, texture, and quality.

Pine River Cheese: A Wisconsin Original

You may want to see also

Frequently asked questions

Camembert is a soft cow's milk cheese with a distinctive white rind and creamy texture. It is one of France's most iconic cheeses and originated in Normandy.

Making Camembert involves heating milk to 90°F (32°C), adding cultures, cutting the curds, draining and drying, and then ripening the cheese for at least three weeks. The surface of the cheese is sprayed with a mould, Penicillium camemberti, which gives it its characteristic rind.

Camembert has a strong, slightly sour, and sometimes chalky flavour. When warmed, it becomes creamier.

Camembert is available in many countries, including the United States and France. It is typically sold in wooden containers or wrapped in paper and placed in cardboard boxes for cheaper varieties.