Goat cheese, also known as Chevre, is a creamy, spreadable cheese with a distinct flavour. It is made using goat's milk, which is combined with heat and acid to separate it into curds and whey. The curds are then collected and drained to form the cheese. This process is known as coagulation and is the oldest method of cheese-making in the world. Goat cheese can be made with just three or four ingredients and is easy to make at home. The ingredients include goat's milk, citric acid, water, and salt. Goat cheese is lower in fat, calories, and cholesterol than cow's milk and is easier on the stomach, making it a good option for those with dairy intolerances.

Ingredients in Goat Cheese

| Characteristics | Values |

|---|---|

| Main Ingredient | Goat's Milk |

| Other Ingredients | Culture, Rennet, Citric Acid, Salt, Water, Vinegar |

| Optional Ingredients | Herbs, Honey, Garlic, Jam, Nuts |

| Nutritional Benefits | Healthy Fats, Protein, Vitamins, Minerals, Calcium, Phosphorus, Copper, Selenium, Magnesium, Niacin (vitamin B3) |

| Other Benefits | Lower in Fat, Calories, and Cholesterol than Cow's Milk, Easier on the Stomach |

| Storage | Consume within a Week to 10 Days, Can be Refrigerated for up to 2 Weeks, Can be Frozen |

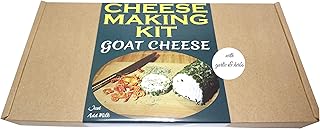

Explore related products

What You'll Learn

- Goat cheese is made from goat's milk, which is lower in fat, calories, and cholesterol than cow's milk

- It is also higher in calcium and easier to digest, making it a good option for those with dairy intolerances

- Goat cheese is creamy and spreadable, with a distinct flavour

- It is a good source of protein, healthy fats, vitamins, and minerals

- Making goat cheese at home is simple and only requires a few ingredients

Goat cheese is made from goat's milk, which is lower in fat, calories, and cholesterol than cow's milk

Goat cheese is known for its creamy, distinct flavor and can be made at home with just a few simple ingredients: goat's milk, culture, rennet, and salt. The process is straightforward and begins by bringing fresh goat's milk to room temperature and adding culture and a few drops of rennet. After stirring and setting the mixture aside for 18-24 hours, the curds are drained in a butter muslin-lined colander and then flavored with salt. This homemade goat cheese, or Chevre, is then ready to be consumed or used in cooking.

The Chevre recipe can be modified to create an aged goat cheese, which involves a brief aging period of about four weeks to allow for the development of a skin and a chalky texture. This aging process further reduces the moisture content and results in a tangier, more concentrated flavor. While this variety of goat cheese represents only a small portion of America's total goat cheese production, it showcases the versatility of goat's milk and the range of flavors and textures that can be achieved through simple adjustments in the cheese-making process.

Goat cheese is a versatile ingredient that can be used in both sweet and savory dishes. It can be spread on crackers, bagels, and bread or crumbled over salads to add a creamy texture and distinct flavor. Additionally, goat cheese has a unique nutritional profile that sets it apart from other types of cheese, making it a popular choice for those seeking a delicious and nutritious option.

Goat Cheese: A Dairy Delicacy?

You may want to see also

It is also higher in calcium and easier to digest, making it a good option for those with dairy intolerances

Goat cheese is a great option for those with dairy intolerances. It is lower in fat, calories, and cholesterol than cow's milk cheese, and it is also easier to digest. This is because goat's milk contains lower levels of lactose and higher levels of calcium.

Goat cheese is made using goat's milk, which is combined with heat and acid to form curds and whey. The curds are then collected and drained to form the cheese. This process is known as "coagulation" and is the oldest method of cheese-making in the world. The goat's milk can be raw or pasteurized, though ultra-pasteurized milk is not recommended as it does not curdle in the same way. The milk is heated to around 86°F (or 20-22°C), and ingredients like salt, vinegar, lemon juice, or citric acid are added to encourage curdling.

Goat cheese is a good source of calcium, as well as protein, healthy fats, vitamins, and minerals. It is also a good source of probiotics, which are beneficial bacteria that can improve gut health. The fatty acids found in goat's milk, such as capric acid, have antibacterial and anti-inflammatory properties, which can be beneficial for those with dairy intolerances.

The process of making goat cheese at home is relatively simple and only requires a few ingredients and basic equipment. The cheese is usually ready to eat in one to three weeks, with ripened goat cheese aged for about four weeks and aged goat cheese requiring six months or more of aging. Homemade goat cheese will last for about one to two weeks in the fridge and can be frozen to maintain its texture and moisture content.

Goat Cheese Diet: Alkaline or Acidic?

You may want to see also

Goat cheese is creamy and spreadable, with a distinct flavour

Goat cheese is a creamy and spreadable cheese with a distinct flavour. It is made from goat's milk, which is combined with heat and acid to form curds and whey. The curds are then collected and drained to make the cheese. This process is known as coagulation and is the oldest method of cheese-making in the world.

Goat cheese typically uses just three or four ingredients: goat's milk, citric acid, water, and salt. Some recipes also call for a few drops of rennet, a coagulating enzyme that can be used to separate milk into curds and whey. The milk should be full-fat and pasteurized, rather than ultra-pasteurized, as this will not curdle in the same way.

Goat cheese can be made at home and is ready to eat in as little as one to three weeks. The cheese can be ripened for longer to develop a stronger flavour. Ripened goat cheese, which represents about 10% of America's goat cheese production, is aged for around four weeks, giving it a chalky texture and tangier taste. Aged goat cheese, making up about 5% of US production, is left for six months or more and has an even lower moisture content and more concentrated flavour.

Goat cheese is a good source of protein, healthy fats, vitamins, and minerals. It is lower in fat, calories, and cholesterol than cow's milk and is often easier to digest, making it a good option for those with an intolerance to cow's milk.

Goat Cheese vs Goat Milk: Which is Healthier?

You may want to see also

Explore related products

It is a good source of protein, healthy fats, vitamins, and minerals

Goat cheese is a good source of protein, healthy fats, vitamins, and minerals. It is made from goat's milk, which has a different protein structure to cow's milk, making it a better choice for those with an intolerance. Goat's milk is also lower in fat, calories, and cholesterol than cow's milk.

Goat cheese is a good source of selenium, magnesium, and niacin (vitamin B3). It also contains calcium, phosphorus, and copper, which are essential for healthy bones. The calcium content in goat cheese is higher than in cow's milk.

The healthy fats in goat cheese include medium-chain fatty acids, which can improve satiety and benefit weight loss. Goat's milk contains more medium-chain fatty acids than cow's milk. These fatty acids have antibacterial qualities and may help reduce inflammation. Goat's milk contains capric acid, a medium-chain fatty acid with antibacterial and anti-inflammatory properties. Studies have found that capric acid is effective in combating P. acnes, a type of bacteria that can contribute to the development of acne.

Goat cheese is also a source of probiotics, which are friendly bacteria that provide numerous health benefits. The specific types of probiotics in goat cheese can vary depending on the production methods used.

Goat Cheese Kosher for Passover: What You Need to Know

You may want to see also

Making goat cheese at home is simple and only requires a few ingredients

Goat cheese is known for its creamy, distinct flavour and can be made using just three to four ingredients. The key ingredients are fresh goat's milk, citric acid or vinegar, and salt. The goat's milk should be full-fat and pasteurized, rather than ultra-pasteurized, as this will not curdle in the same way. You can use raw goat's milk if you are able to source it.

To make the cheese, begin by warming the milk to 68-72°F (20-22°C) in a pot or sink of warm water. You can also allow the milk to cool naturally to this temperature for an hour or so if it is fresh. Next, add the citric acid or vinegar and stir gently. Allow the mixture to sit for 10-15 minutes until it looks clumpy on top and is watery yellow in colour.

Line a colander with a towel or cheesecloth and pour the mixture into it. Tie the corners and hang it to drip for about 20 minutes. Once the curds have been collected and drained, the cheese is ready to be flavoured with salt and any optional flavourings such as herbs, honey, garlic, or nuts. The cheese can then be chilled and stored in a covered bowl. It is best consumed within a week to ten days, but can also be frozen to maintain its texture and moisture content.

Goat Cheese Halal Status: What Muslims Should Know

You may want to see also

Frequently asked questions

The ingredients in goat cheese are goat's milk, citric acid, water, and salt. Some recipes also include vinegar, apple cider vinegar, or lemon juice to help the milk curdle.

It takes 18-24 hours for the cheese to set. The cheese is then ready to eat in two to three weeks and can be ripened longer for more flavour.

Goat cheese lasts between one and two weeks in the fridge. It can be frozen and will last up to six months.

The process for making goat cheese is known as coagulation. Goat's milk is combined with heat and acid, breaking down the milk into curds and whey. The curds are then collected and drained to make the cheese.

Goat cheese is lower in fat, calories, and cholesterol than cow's milk. It is also easier on the stomach and can be consumed by people with an intolerance to cow's milk. Goat cheese is also a good source of protein, healthy fats, vitamins, and minerals.