Blue cheese is made using copper wire. This is a myth, however. The mould in blue cheese grows when air is introduced during the cheesemaking process. Cheesemakers use steel rods to poke holes in the cheese, not copper wire. Blue cheese is made by mixing bacteria with curds before shaping them. The cheese is then pierced to create tunnels that allow air to enter and feed the bacteria, encouraging mould veins. Penicillium roqueforti is a type of bacteria used in cheesemaking to create the characteristic green-blue mould found in Gorgonzola.

| Characteristics | Values |

|---|---|

| Use of Copper Wire | Copper wire is not used to make cheese. However, it was once a myth that copper wire was used to create the edible mould in blue cheese. |

| Mould Formation | In blue cheese, mould forms when air is introduced during the cheesemaking process. |

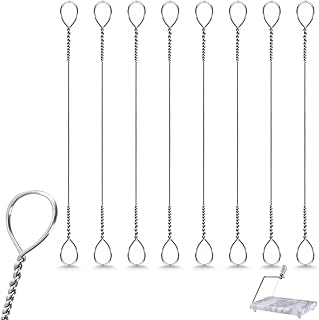

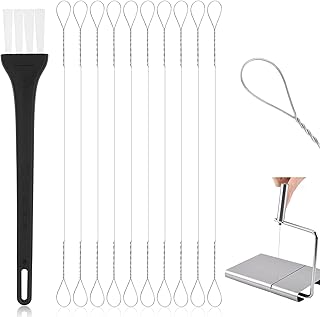

| Air Introduction | Some artisanal cheesemakers use knitting needles to poke holes in the cheese, while most modern cheesemakers use steel rods. |

| Texture | The texture varies from soft and creamy to crumbly and dry, with younger cheeses being softer and older cheeses being drier. |

| Ingredients | All cheese is made with milk, salt, and a coagulant such as acid or rennet. |

| Curds and Whey | The mixture is heated to form curds and whey; the whey is drained, and the curds are pressed and/or shaped. |

| Types of Blue Cheese | Examples include Roquefort, Gorgonzola, Stilton, Danish Blue (Danablu), Saint Agur, Shadows of Blue, Blue Orchid, Gippsland Blue, Milawa Blue, Aged Blue, and Hunter Belle Blue Moon. |

| Taste | Blue cheese can have a sharp, salty, or creamy taste, with variations depending on the type and region. |

Explore related products

$16.99 $21.99

$8.99 $9.99

What You'll Learn

- Blue cheese is made using steel rods, not copper wire

- Penicillium roqueforti is used to create the mould in blue cheese

- Blue cheese is made by piercing holes for air to enter and feed the bacteria

- Examples of blue cheese include Gorgonzola, Roquefort, and Stilton

- Blue cheese can be made from cows' or sheep's milk

Blue cheese is made using steel rods, not copper wire

Once the cheese mixture has been heated to form curds and whey, the whey is drained, and the curds are pressed and/or shaped. At this stage, the cheese is 'needled' or pierced to create little tunnels that allow air to enter and feed the bacteria, encouraging the mould veins to form. While some artisanal cheesemakers use knitting needles to poke holes in the cheese, most cheesemakers today use steel rods for this process.

Blue cheese gets its characteristic green-blue mould from the bacteria Penicillium roqueforti, which was reportedly discovered in France as early as 74 AD. The first blue cheese, Roquefort, made from sheep's milk, is considered one of the most well-known and beloved blue cheeses globally. Other popular blue cheeses include the Italian Gorgonzola, made from cow's milk, and the English Stilton, which originated in the village of Stilton in Cambridgeshire in 1730.

Today, blue cheese is made by various producers worldwide, including the Grubb family from Beechmount Farm in Tipperary, Ireland, who create Cashel Blue, and Victoria's Tarago River in Australia, which produces several cow's milk blues, such as Shadows of Blue and Gippsland Blue. While the production methods and ingredients may vary slightly between different cheesemakers, steel rods remain the standard tool for creating the air tunnels in blue cheese, not copper wire.

Kunafa: The Cheesy Delicacy's Secret

You may want to see also

Penicillium roqueforti is used to create the mould in blue cheese

Blue cheese is divisive—some love it, while others hate it. To cater to "beginner tasters", cheesemakers have started producing milder blue cheeses. Contrary to popular belief, copper wire does not create the edible mould in blue cheese. Instead, the mould forms when air is introduced during the cheesemaking process. Cheesemakers use steel rods or knitting needles to poke holes in the cheese and allow air to enter.

Penicillium roqueforti is a type of bacteria that is used to create the mould in blue cheese. It was reportedly discovered in France in 74 AD, and the first blue cheese, Roquefort, was made from sheep's milk. Penicillium roqueforti is a naturally occurring bacteria that grows in the cracks and holes of blue-veined cheeses. It has a wide pH growth range of 3.0–10.5 and can grow at low oxygen levels and high carbon dioxide levels, making it well-suited for the environment in which blue cheese is made.

Penicillium roqueforti is added to the curds just before they are shaped to create the distinctive veins and flavours of blue cheese. It breaks down protein and fat, yielding the textures, aromas, and flavours characteristic of blue cheese. The mould can appear in diverse colours, from green-blue to white, depending on the specific strain of Penicillium roqueforti used.

Penicillium roqueforti is also used in the production of other blue cheeses, such as Gorgonzola, Stilton, and Cashel Blue. It plays a critical role in developing the flavour and texture of these cheeses through its enzymatic activity. The Grubb family from Beechmount Farm in Tipperary, Ireland, has been making Cashel Blue since the late 1980s using Penicillium roqueforti.

Philly Cheesesteak: The Cheese Secrets Revealed

You may want to see also

Blue cheese is made by piercing holes for air to enter and feed the bacteria

Blue cheese is a divisive food—people tend to either love it or hate it. It is made by mixing bacteria with the curds, then piercing the cheese to create small tunnels that allow air to enter and feed the bacteria, encouraging mould veins to form. This process is called 'needling' and is done after the curds have been shaped. While some artisanal cheesemakers use knitting needles to create these holes, most modern cheesemakers use steel rods instead.

The mould used in blue cheese is called Penicillium roqueforti, a naturally occurring bacteria reportedly discovered in France in 74 AD. Roquefort, the first blue cheese, was made from sheep's milk and is still one of the most well-known and loved blue cheeses worldwide. Other popular blue cheeses include Italian Gorgonzola, made from cow's milk, and English Stilton, first made in the village of Stilton, Cambridgeshire, in 1730.

Blue cheese can vary in texture from very soft and creamy to crumbly and dry, with younger cheeses tending to be softer and older cheeses drier. The flavour of blue cheese can also vary, ranging from sweet and buttery to strong and savoury. Some blue cheeses, like Danish blue (also known as Danablu), have a sharp, almost metallic taste with salty overtones.

While copper wire was historically used to create the edible mould in blue cheese, this is no longer the case. The mould in blue cheese forms when air is introduced during the cheesemaking process, and the use of copper wire has been replaced by the needling method described above.

Pizza Hut's Cheese Blend: The Secret Recipe Revealed

You may want to see also

Explore related products

Examples of blue cheese include Gorgonzola, Roquefort, and Stilton

Blue cheese is made in a similar way to white mould cheeses like Camembert or Brie. However, instead of being sprayed with mould to encourage surface bacteria, blue cheese has bacteria mixed through the curds just before they are shaped. After shaping, the cheese is 'needled'—pierced to create little tunnels to allow air to enter and feed the bacteria, encouraging mould veins.

Roquefort is also one of the first blue cheeses, made from sheep's milk. It is named after the French village of Roquefort-sur-Soulzon, where it is produced. Roquefort remains one of the most loved and best-known blue cheeses in the world. It was granted the first AOC (Appellation d’Origine Controlee) in 1925, decreeing that the Penicillium roqueforti used in production must be from the caves of Roquefort-sur-Soulzon.

Stilton blue cheese was first sold in the village of Stilton in England, though there is little evidence it was ever made there. It is made from pasteurized cow's milk. In addition to being inoculated with Penicillium roqueforti to give it the blue vein characteristic, research has shown that other microbiota, such as relatives of Lactococcus lactis, Enterococcus faecalis, and Lactobacillus plantarum, can also be found in Stilton cheese.

Crafting Butter with Cheesecloth: A Step-by-Step Guide

You may want to see also

Blue cheese can be made from cows' or sheep's milk

Blue cheese is made in a similar way to white mould cheese, like Camembert or Brie. However, instead of being sprayed with mould to encourage surface bacteria, blue cheese has bacteria mixed throughout its curds before shaping. After the cheese is shaped, it is "needled", which means piercing it to create little tunnels that allow air to enter and feed the bacteria, encouraging mould veins. This process is how blue cheese gets its distinctive appearance.

Contrary to popular belief, copper wire is not used to create the edible mould in blue cheese. Instead, the mould grows when air is introduced during cheesemaking. While some artisanal cheesemakers may use knitting needles to poke holes in the cheese, most modern cheesemakers use steel rods.

Blue cheese can be made from either cow's or sheep's milk. For example, Italy's best-known blue cheeses, Gorgonzola Dolce and Gorgonzola, are made from cow's milk. Gorgonzola Dolce is known for its sweet and buttery flavour, while its older counterpart, Gorgonzola, has a stronger taste. Victoria's Tarago River also produces three types of blue cheese from cow's milk: Shadows of Blue, Blue Orchid, and Gippsland Blue, each with varying levels of creaminess and "blueness". On the other hand, Roquefort, one of the world's most renowned and beloved blue cheeses, is made from sheep's milk.

Blue cheese is known for its distinctive flavour and texture, which can vary from soft and creamy to crumbly and dry, depending on its age. While some people love blue cheese, others dislike it due to its strong taste and smell. However, there are now blue cheeses being made for "beginner tasters", with milder flavours designed to entice those who are not typically fans of blue cheese.

Cheese Cubes: Appetizers to Snacks

You may want to see also

Frequently asked questions

It is a common misconception that copper wire is used to create the edible mould in blue cheese. In reality, the mould in blue cheese forms when air is introduced during the cheesemaking process.

After the curds are shaped, the cheese is pierced with steel rods or knitting needles to create little tunnels to allow air to enter and feed the bacteria, encouraging the mould veins.

Some well-known blue cheeses include Roquefort, Gorgonzola, Stilton, and Cashel Blue.