The shape of a cheese is dictated by concerns with pressure, salt absorption, ripening, economics, and tradition. For example, cheddar is made in round wheels and then cut into squares, while provolone is traditionally sliced in circles. The square shape of a cheese is often a result of the large blocks that are cut into smaller blocks for consumer usage, as blocks are easier and more economical to stack, store, and transport over long distances.

| Characteristics | Values |

|---|---|

| Shape | Square |

| Type | Pack Square |

| Texture | Soft-ripened |

| Taste | Buttery, creamy |

| Colour | Golden |

| Rind | Bloomy |

| Milk | Jersey cow milk |

| Cutting | Cut into squares from a wheel |

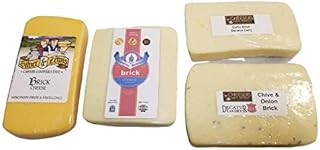

Explore related products

$3.62 $4.49

What You'll Learn

Square cheese is often cut from larger wheels of cheese

The shape of a cheese is dictated by several factors, including pressure, salt absorption, ripening, economics, and tradition. Square cheese is often cut from larger wheels of cheese. This is done for retail and deli sales, as very few people would buy a whole wheel of cheese. The wheel is cut into blocks, which are easier to stack, store, and transport over long distances.

Different types of cheese go through different processes to achieve their desired flavour and texture. For example, wheel cheeses are usually hard and aged for a long time to develop a strong flavour, such as Parmesan. The process of making this type of cheese has been refined over time, and the methods used require the cheese to be shaped into a wheel.

Additionally, the wheel shape facilitates even salt absorption and ripening. The consistent thickness of a wheel-shaped cheese encourages equal absorption of salt, and the surface flora can spread evenly. In contrast, a square-shaped cheese may have issues with over-ripening on the edges, where a higher percentage of mould would focus its action.

Some cheeses, such as Provolone, are made and sold in various shapes, including pear-shaped, log-shaped, and round. The shape of Provolone is not essential to its production process, but rather a matter of tradition and sales appeal.

Soy-Based Cheeses: How Are They Made?

You may want to see also

Square cheese is cut to ensure equal amounts of rind

The shape of a cheese is determined by various factors, including pressure, salt absorption, ripening, economics, and tradition. Square cheese is often cut to ensure equal amounts of rind for consumers. This is especially true for large wheels of cheese, which are typically cut into more manageable square blocks for retail and deli sales.

Cheddar cheese is a prime example of a cheese that is often produced in round wheels and then cut into square blocks. These large wheels can weigh 300 pounds or more, and it is impractical to sell them in their original form, as few consumers would purchase such a large quantity of cheese. Therefore, the wheels are cut into smaller, more marketable portions.

The process of cutting a round wheel of cheese into squares also helps ensure that each piece has a similar flavour and texture. Different parts of the wheel have distinct characteristics, so cutting it into wedges that include a bit of each part provides a consistent experience for the consumer. This is in contrast to cheeses like Provolone, which is often sold in various shapes, including pear, log, and round, as its shape does not impact its sales.

Additionally, the square shape of cheese blocks makes them easier to stack, store, and transport over long distances. The uniform shape allows for efficient packing and maximises space utilisation. This is particularly advantageous for retailers and distributors who need to manage inventory and transport cheese over significant distances.

In summary, square cheese is often cut to ensure equal distribution of rind and provide consumers with a consistent product. The practicalities of production, distribution, and sales also play a role in the prevalence of square cheese blocks, making them a common sight in delis and retail stores.

Godminster Cheese: Handmade in Rural England

You may want to see also

Square cheese is cut to include different flavours and textures

Cheeses like Cheddar are often made in large round wheels and then cut into squares for retail and deli sales. This is because the wheels are so big that it doesn't make sense to sell them in their original form, as very few people would buy such a large quantity of cheese. Cutting the cheese into smaller portions ensures that everyone who buys a piece gets an equal amount of rind and a variety of flavours and textures.

For example, different parts of a cheese wheel can have different flavour and texture characteristics. The centre of the wheel is considered the most prized part, with a creamy, buttery interior. By cutting the cheese into wedges, everyone can get a taste of the various flavours and textures the cheese has to offer.

Additionally, the shape of the cheese can influence the ripening process. Cheeses that are made in wheels, like Brie and Camembert, need equal rates of salt uptake and even ripening action from moulds. The consistent thickness of a wheel-shaped cheese encourages uniform absorption, preventing over-ripening in certain areas.

Square cheese, therefore, is not only a result of practical considerations but also a way to ensure that consumers get to experience the different flavours and textures that the cheese has to offer.

Cooper Cheese: Where is the CV Sharp Made?

You may want to see also

Explore related products

$6.59

Square cheese is easier to stack, store and transport

The shape of a cheese is dictated by concerns of pressure, salt absorption, ripening, economics, and tradition. While some cheeses are made in wheels, like creamy Brie and Camembert, others are made in blocks, like Cheddar. The reason for the wheel shape is to facilitate even salt absorption and ripening action from moulds. The consistent thickness of the wheel shape encourages equal absorption as the surface flora spread, preventing over-ripening in certain areas, which can be a problem with square blocks if conditions are not carefully controlled.

However, square cheese is often a result of large cheese wheels being cut into square blocks for retail and deli sales. This is because large wheels of cheese, which can weigh over 300 pounds, are difficult to manage and store, and it is more economical to cut them into blocks for consumers. In the case of Cheddar, for example, the cheese is made in round wheels and then cut into squares. This is because the wheels are so large that few people would buy them whole, and the blocks are easier to stack, store, and transport.

Square cheese is also a result of the technology and equipment used in cheese production. Vacuum pressure is used to press blocks of cheese into towers, which are then packed into a larger block and pressed again in a vacuum chamber prior to cold storage. These blocks make sense given the technology and equipment available.

Square cheese is also easier to package and sell to consumers. Processed American cheese, for example, is packaged in individually wrapped slices, as unwrapped slices sold in stacks, or in unsliced blocks. Blocks of American cheese are sliced to order at deli counters and are a common choice for sandwiches because of their versatility.

Mrs. Bell's Blue Cheese: A Tasty Treat's Origin Story

You may want to see also

Square cheese is often packaged in slices or blocks

The shape of a cheese is influenced by factors such as pressure, salt absorption, ripening, economics, and tradition. Square cheese is often packaged in slices or blocks for convenience and to facilitate stacking, storage, and transportation.

Cheeses like cheddar are typically produced in large, round wheels and then cut into square blocks for retail and deli sales. The large wheels are challenging to manage, and cutting them into smaller portions ensures that the cheese can be easily packaged and sold to consumers. This practice also ensures that everyone who purchases a piece receives a similar amount of rind and cheese characteristics, preventing unfair distribution.

The process of cutting large wheels into square blocks is common in cheese production. Vacuum pressure is applied to press the cheese into "towers," which are then combined into larger blocks and placed in a vacuum chamber for further pressing and aging. Blocks are preferred for their compatibility with modern technology and equipment, making storage and handling more manageable.

Additionally, the shape of the cheese influences the flavor and texture characteristics. Cheeses that rely on molds, such as brie and Camembert, require equal rates of salt uptake and even ripening action. The wheel shape facilitates this process, ensuring consistent thickness and preventing over-ripening in corners that square blocks may experience.

Square cheese packaging in slices or blocks is a practical approach to distributing and consuming cheese. It allows for convenient stacking, storage, and transportation, making it a popular choice for consumers and the food industry.

Cheese for Nachos: Choosing the Perfect Melty Cheese

You may want to see also

Frequently asked questions

Square cheese is not made of anything specific. The shape of the cheese does not determine its ingredients. However, the shape of the cheese does determine how it is cut and sold.

Square cheese is cut into squares for convenience and to make it easier to transport. Large wheels of cheese are cut into squares for retail and deli.

Cheddar is a popular example of a cheese that is cut into squares. Other examples include mozzarella and American cheese.

Cheeses that are made in wheels, like creamy brie and Camembert, are not cut into squares. This is because the wheel shape facilitates equal salt absorption and even ripening action from its moulds.