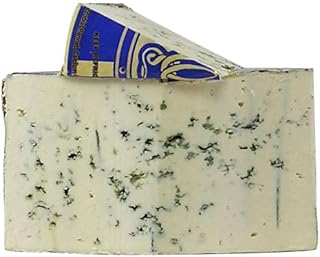

Blue cheese is any cheese made with the addition of cultures of edible moulds, which create blue-green spots or veins throughout the cheese. The mould responsible for the characteristic blue-green veins of blue cheese is the fungus Penicillium roqueforti. This fungus has been used for centuries as a maturation agent in blue cheese and is also responsible for the distinctive texture and aroma of the cheese.

| Characteristics | Values |

|---|---|

| Scientific Name | Penicillium roqueforti |

| Common Name | Blue-cheese fungus |

| Genus | Penicillium |

| Type | Filamentous fungus (mold) |

| Colour | Light to dark greenish-gray with shades of gray, yellowish, and olive-green |

| Texture | Velvety to fasciculate |

| Size | 3 to 4.5 μm diameter |

| Shape | Spherical and smooth |

| Tolerance | Cold temperatures, low oxygen levels, alkali preservatives, and weaker acid preservatives |

| Industrial Uses | Production of blue cheeses, flavouring agents, antifungals, polysaccharides, proteases, and enzymes |

| Biotechnological Uses | Production of metabolites like the immunosuppressant mycophenolic acid |

| Health Risks | Produces harmful secondary metabolites (alkaloids and mycotoxins) under certain conditions |

| Health Benefits | Potential value in cancer treatment due to secondary metabolites inhibiting multidrug-resistant cancer cells |

Explore related products

What You'll Learn

- Penicillium roqueforti is the fungus most commonly used in blue cheese production

- Other types of fungus used include Penicillium glaucum and Penicillium camemberti

- Blue cheese is made by adding fungal inoculum as a starter culture during cheese production

- The fungus produces volatile and non-volatile flavour components and changes the texture of the cheese

- The characteristic blue-green veins of blue cheese arise from fungal sporulation

Penicillium roqueforti is the fungus most commonly used in blue cheese production

Penicillium roqueforti is a saprophytic fungus commonly found in nature. It can be isolated from soil, decaying organic matter, and plants. The fungus is well-known for its use in the production of blue-veined cheeses, such as Roquefort, Stilton, Danish blue, Cabrales, and others. The chief industrial use of this species is, in fact, the production of blue cheeses.

P. roqueforti is added as a starter culture during the cheese production process. It is responsible for the characteristic blue-green veins and spots, texture, and aroma of blue cheeses. The fungus produces volatile and non-volatile flavour components through its metabolic action. It also contributes to the ripening process by producing proteolytic and lipolytic enzymes, which soften the curd and give the desired body to the cheese.

The use of P. roqueforti in blue cheese production has a long history. According to legend, one of the first blue cheeses, Roquefort, was discovered when a young boy's bread and ewes' milk cheese was left in a cave and transformed by the mould. Since then, P. roqueforti has been used for centuries as a maturation agent in blue cheese production.

While P. roqueforti is known for its role in creating the desired characteristics of blue cheese, it also has the potential to produce harmful secondary metabolites, such as alkaloids and mycotoxins, under certain growth conditions. However, the levels of these toxins in cheese are usually too low to produce toxic effects, and the cheese-making process involves specific strains and conditions that further reduce the risk of toxin production.

In summary, Penicillium roqueforti is the fungus most commonly used in blue cheese production, contributing to the distinctive characteristics of this type of cheese.

The Best Cheeses for Greek Saganaki

You may want to see also

Other types of fungus used include Penicillium glaucum and Penicillium camemberti

Blue cheese is made with the addition of cultures of edible moulds, which create blue-green spots or veins throughout the cheese. The most common fungus used in blue cheese production is Penicillium roqueforti, a common saprotrophic fungus that can be isolated from soil, decaying organic matter, and plants. However, other types of fungi used include Penicillium glaucum and Penicillium camemberti.

Penicillium glaucum is used in some blue cheeses, such as Gorgonzola, instead of Penicillium roqueforti. It is responsible for the blue veins in these cheeses. On the other hand, Penicillium camemberti is a filamentous fungus well known for its use in the production of exterior mould-ripened cheeses. This fungus is added as a starter culture during cheese production and contributes to the flavour and texture of the cheese.

Both Penicillium glaucum and Penicillium camemberti have been selected and adapted for use in cheese production through a process of domestication. This involves the selection of environmental microorganisms that have become adapted to a human-provided niche, accompanied by the loss of unwanted traits and the gain of favourable properties. For example, Penicillium glaucum and Penicillium camemberti have likely been selected for their ability to produce desirable flavours and textures in cheese, as well as their safety for human consumption.

The use of these fungi in blue cheese production allows for the creation of a variety of flavours, textures, and appearances that are favoured by consumers. The domestication and selection of specific strains of Penicillium glaucum and Penicillium camemberti have likely played a role in the development of new cheese varieties and the improvement of existing ones.

In conclusion, while Penicillium roqueforti is the most common fungus used in blue cheese production, Penicillium glaucum and Penicillium camemberti are also important fungi that contribute to the diverse and complex flavours, textures, and characteristics of blue cheeses. The use of these fungi in cheese production showcases the art of microbial domestication and the human ability to adapt and utilize microorganisms for desirable outcomes.

Limburger Cheese: Delicious Ways to Use It

You may want to see also

Blue cheese is made by adding fungal inoculum as a starter culture during cheese production

The chief industrial use of this species is the production of blue cheese, where the fungus is added as a starter culture. Blue cheese is any cheese made with the addition of cultures of edible moulds, which create blue-green spots or veins throughout the cheese. The mould Penicillium roqueforti is responsible for the characteristic texture, blue-green spots, and aroma of blue-veined cheeses. The fungus produces volatile and non-volatile flavour components and changes in cheese texture due to its metabolic action. It is also responsible for the blue-green colour of the cheese veins due to the pigmentation of the conidia produced during fungal development.

The process of making blue cheese involves preparing a Penicillium roqueforti inoculum before the actual production of the cheese. This involves using a freeze-dried Penicillium roqueforti culture, which is activated by adding water. Salt, sugar, or both are added to autoclaved, homogenized milk via a sterile solution, which is then inoculated with the fungus. This mixture is then used to create the cheese.

Blue cheese is believed to have been discovered by accident when cheeses were stored in caves with naturally controlled temperature and moisture levels that happened to be favourable environments for the growth of harmless mould. The "good" mould prevents other moulds and bacteria from growing once it gets a foothold, which is why blue cheese is safe to eat.

Mozzarella, Cheddar, and Beyond: Choosing Pizza Cheeses

You may want to see also

Explore related products

The fungus produces volatile and non-volatile flavour components and changes the texture of the cheese

Blue cheese is made with the addition of cultures of edible moulds, which create blue-green spots or veins throughout the cheese. The fungus responsible for this transformation is Penicillium roqueforti, a common saprotrophic fungus in the genus Penicillium. It is widespread in nature and can be isolated from soil, decaying organic matter, and plants.

The texture of the cheese is also altered by the growth of P. roqueforti. The fungus produces a velutinous felt of conidiophores, which are the structures that bear the spores. The spores themselves, called conidia, are dark green and spherical, with a diameter of 3 to 4.5 μm. This combination of metabolic action and physical growth of the fungus results in the distinctive texture and appearance of blue cheese.

In addition to its use in blue cheese production, P. roqueforti has been considered for other biotechnological purposes due to its ability to produce various metabolites. For example, it can be used to produce the immunosuppressant agent mycophenolic acid and lipase extracts through solid-state fermentation. The study of this fungus and its ability to produce diverse metabolites has led to its consideration for potential biotechnological applications.

The process of making blue cheese involves preparing an inoculum of P. roqueforti before adding it to milk or curd. This inoculum is typically made from a freeze-dried culture of the fungus, which is activated by adding water. Salt, sugar, or both are then added to autoclaved, homogenized milk, and this mixture is inoculated with P. roqueforti to begin the transformation into blue cheese.

Cheese Options for Arepas: A Quick Guide

You may want to see also

The characteristic blue-green veins of blue cheese arise from fungal sporulation

Blue cheese is any cheese made with the addition of cultures of edible moulds, which create blue-green spots or veins throughout the cheese. The characteristic blue-green veins of blue cheese arise from fungal sporulation. The mould responsible for this transformation is called Penicillium roqueforti, a common saprotrophic fungus in the genus Penicillium. It was first described by American mycologist Charles Thom in 1906 as a heterogeneous species of blue-green, sporulating fungi.

P. roqueforti is added as a starter culture during cheese production and is responsible for the distinctive flavour, texture, and colour of blue cheeses. It can tolerate cold temperatures, low oxygen levels, and preservatives, allowing it to thrive in dairy environments. The fungus produces volatile and non-volatile flavour components and changes the texture of the cheese through its metabolic action. It also synthesises secondary metabolites, including mycotoxins and compounds with potential medicinal value, such as the immunosuppressant agent mycophenolic acid.

The process of making blue cheese involves preparing an inoculum of P. roqueforti before adding it to milk or curd. Salt, sugar, or both are added to autoclaved, homogenised milk, which is then inoculated with the fungus. This introduction of "'good'" mould prevents other moulds and bacteria from growing and spoiling the cheese. Blue cheeses are then typically aged in temperature-controlled environments.

While P. roqueforti is the most common fungus used in blue cheese production, some varieties, such as Gorgonzola, use Penicillium glaucum to achieve their distinctive colour and flavour. Additionally, studies have been conducted to modify the spore coat colours of P. roqueforti, resulting in "non-blue" cheeses with different colours in the cavities of the cheese. These modified strains have comparable or lower levels of roquefortine C, a neurotoxin produced by P. roqueforti, ensuring the cheese remains safe for consumption.

Creative Uses for Chuck E. Cheese Tokens

You may want to see also

Frequently asked questions

The fungus used in blue cheese is called Penicillium roqueforti, which is a common saprotrophic fungus in the genus Penicillium.

Penicillium roqueforti is responsible for the distinctive texture, blue-green spots, and aroma of blue-veined cheeses. It also produces different secondary metabolites, including mycotoxins and immunosuppressants.

Yes, blue cheese is safe to eat. The "good" mold in blue cheese prevents other molds and bacteria from growing. However, it's probably not a good idea to over-consume blue cheese, even if it's tolerable in small quantities.

Some popular blue cheeses include Roquefort, Stilton, Danish Blue, Cabrales, Gorgonzola, Bleu de Bresse, and Shropshire Blue.

Blue cheese is made by adding an inoculum of Penicillium roqueforti to milk or curd. The cheese is then aged in a temperature-controlled environment. Blue cheese is believed to have been discovered by accident when cheeses were stored in caves with naturally controlled temperatures and moisture levels, creating favorable conditions for the growth of harmless mold.