Grana Padano is an Italian cheese made from unpasteurized, partially skimmed cow's milk. The cows are milked twice a day, and the milk produced in the evening is mixed with fresh milk from the morning to create a semi-skimmed milk. This milk mixture is then combined with whey and animal-derived rennet to form curds, which are then shaped into wheels and soaked in brine to extract moisture and initiate the aging process. The aging process for Grana Padano cheese typically lasts between nine and 20 months, during which the cheese develops its characteristic flavour, texture, and nutritional profile.

| Characteristics | Values |

|---|---|

| Milk Type | Cow's milk |

| Pasteurization | Unpasteurized |

| Skimmed | Partially skimmed |

| Rennet | Calf rennet |

| Lysozyme | Added |

| Curing Time | Minimum of 9 months |

| Curing Time Range | 9-20 months |

| Curing Time (Extended) | 16-20 months |

| Curing Temperature | 31-33°C (88-91°F) |

| Aging Temperature | 40°F |

| Nutritional Content | 398 kilocalories (1,666 kJ) per 100 grams |

| Lactose Content | Nearly lactose-free |

| Galactose Content | Less than 10 mg per 100 g |

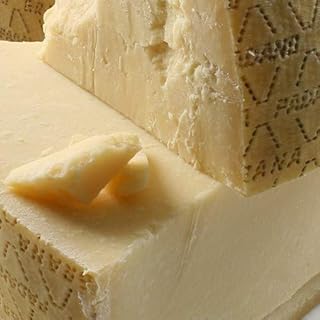

| Texture | Hard, crumbly, flaky, grainy |

| Rind | Thick, golden, edible |

| Serving Suggestions | Antipasti, cheeseboard, grated over pasta or risotto, beef carpaccio |

Explore related products

What You'll Learn

Grana Padano is made from unpasteurised skimmed cows' milk

Grana Padano is a hard, flaky, aged Italian cheese that originated in the Po River Valley in northern Italy. It has a grainy texture, which is why it's classified as a "grana" cheese, with "grana" meaning "grain" in Italian. The recipe for Grana Padano was developed by Cistercian monks in the 12th century, and the same recipe is still used today, albeit with slightly updated equipment.

Grana Padano is made from unpasteurised skimmed cow's milk. The cows are milked twice a day, once in the morning and once in the evening, and the two types of milk are mixed together to create a semi-skimmed milk. The evening milk is skimmed to remove the surface layer of cream and mixed with the fresh morning milk. This milk mixture is then poured into traditional copper cauldrons and mixed with whey and animal-derived rennet to form curd. The curd is then heated, rested, and shaped into wheels. The wheels are then soaked in brine, dried, and aged for at least nine months before they can be sold.

The use of unpasteurised skimmed cow's milk gives Grana Padano a lower fat content, which allows it to mature quickly. This is why it has a minimum ageing period of nine months, compared to the longer ageing period of its counterpart, Parmigiano Reggiano. The ageing process can span anywhere from nine to 20 months, with longer-aged Grana Padano developing more complex flavours.

The production of Grana Padano follows strict regulations, with the milk sourced from local farms with well-defined and regulated processes. The cows are fed fresh forage, hay, corn silage, or preserved fodder, and the milk is partially skimmed through natural surface skimming to remove most of the clostridia, a type of microorganism. The partial skimming also contributes to the cheese's reduced lipid content.

Cheese and Onion: Green Packets, Why the Change?

You may want to see also

The cows are milked twice a day

The cows used in the production of Grana Padano cheese are milked twice a day, once in the morning and once in the evening. The morning milk is typically lower in fat content, and the two milks are mixed together to create a semi-skimmed milk that is left unpasteurized. This process respects the characteristics of the milk and is a key step in the production of Grana Padano.

The cows used for milk production are fed on fresh forage, hay, corn silage, or preserved fodder. This diet is part of the traditional fodder conservation technique known as silage, which is typical of the Po River Valley in Northern Italy. The cows have free access to an automatic milking system, ensuring their comfort and well-being.

The raw milk produced is then partially skimmed by natural surface skimming, removing the surface layer of cream. This process helps to eliminate most of the clostridia, a type of microorganism. However, some of these microorganisms may remain and find conditions to develop during the long ageing of the cheese. To address this, lysozyme, a naturally occurring protein, is added to control the negative effects of Clostridium Tyrobutirricum's development.

The partially skimmed milk is then placed into traditional bell-shaped copper cooking cauldrons or vats, where it undergoes further processing to transform it into cheese. Each cauldron produces two wheels of cheese, known as "twin wheels." The milk is mixed with whey and animal-derived rennet to form curd, which is then shaped into wheels and soaked in brine, beginning the aging process.

The aging process for Grana Padano cheese can span anywhere from nine to 20 months, with a minimum of nine months required before it can be sold. During this time, the cheese develops its signature nutty aroma and flavour. The ageing also contributes to its low moisture content, which gives it a longer shelf life.

Gran Padano: The Perfect Cheese for Your Dish

You may want to see also

The milk is partially skimmed by natural surfacing of the cream

Grano Padano is an Italian cheese that originates in the Po Valley. It is made from unpasteurized cows' milk that is semi-skimmed or partly skimmed. The milk produced in the evening is skimmed to remove the surface layer of cream and mixed with fresh milk produced in the morning. This process of skimming milk involves removing the fat or milkfat from whole milk. In the context of Grano Padano, the natural surfacing of the cream occurs when the milk is left to sit, allowing the fat, which is less dense, to rise to the top. This cream is then skimmed off, leaving partially skimmed milk behind.

Skimmed milk, also known as skim milk in American English, is a type of milk with all the milkfat removed, typically containing around 0.1% to 0.3% fat. The process of skimming milk can be done by hand or through industrial methods, such as using centrifuges called "separators" to accelerate the separation of cream. The cream that rises to the top of milk can be used in various culinary applications, including in the production of butter, whipped cream, and sour cream.

In the context of dairy production and cheese-making, partially skimmed milk is often used to strike a balance between the desired fat content and the desired yield of the final product. For example, in the case of Grano Padano, the use of partially skimmed milk contributes to the characteristic texture and flavour of the cheese. Additionally, the amount of fat in the milk can influence the yield of the cheese, with a higher fat content generally resulting in a lower yield.

The process of partially skimming milk also has implications for the nutritional content of the milk and the resulting cheese. Skimmed milk has been recommended by nutrition guidelines due to its lower saturated fat content, which has been linked to increased cholesterol levels and a higher risk of heart disease. However, recent studies have called these guidelines into question, suggesting that moderate consumption of saturated fat may not directly contribute to heart disease.

In summary, the process of partially skimming milk by natural surfacing of the cream is an important step in the production of Grano Padano cheese. It involves removing the surface layer of cream that has risen to the top of the milk, resulting in a partially skimmed milk that contributes to the unique characteristics of this Italian cheese.

Cheese Wedges: Gymnasts' Secret Weapon Explained

You may want to see also

Explore related products

The milk is placed in copper cauldrons and mixed with whey and rennet

Grana Padano is a semi-fat hard cheese made from unpasteurised skimmed cow's milk. The cows are milked twice a day, and the milk produced in the evening is skimmed to remove the surface layer of cream and mixed with fresh milk produced in the morning. The milk comes from cows fed on fresh fodder, hay, corn silage, or preserved fodder. The feeding of high-quality silage fodder is allowed, and the cheese is produced from two consecutive milkings stored at 8°C on the farm.

Once the milk is partially skimmed, it is placed in traditional bell-shaped copper cooking cauldrons or vats. Each cauldron produces two wheels of cheese, known as "twin wheels". The milk coagulates in the copper cauldrons, and the resulting curd is cut to produce granules the size of rice grains, giving the cheese its characteristic texture. The mixture is then warmed to 53–56°C (127–133°F).

Lysozyme, a protein naturally present in human breast milk, tears, and saliva, is added to the vats to prevent swelling during the ripening process. The lysozyme used in the Grana Padano production process is extracted from hen egg whites. The addition of non-starter lactic acid bacteria also affects the resulting microbiota, giving the cheese its typical characteristics.

Animal rennet is used in the production process, which is strictly protected due to the cheese's PDO status. As a result, Grana Padano is not suitable for vegetarians. However, the cheese is naturally lactose-free despite being made almost entirely from milk.

Delicious Ways to Use Asiago Cheese

You may want to see also

The curd is heated, rested and shaped into wheels before being soaked in brine

Grana Padano is a hard, flaky, aged Italian cheese made from unpasteurized cow's milk. The cows are milked twice a day, once in the morning and once in the evening. The milk produced in the evening is mixed with fresh milk from the morning to create a semi-skimmed milk. This milk mixture is then heated and transformed into curds.

The curds are then heated to a maximum temperature of 53–56 °C (127–136 °F). Once this temperature is reached, the cooking is completed, and the curd granules settle at the bottom of the copper cauldron. The curd granules are then left to rest in the copper cauldron, immersed in the whey, for a maximum of 70 minutes. This allows the granules to aggregate and form a compact mass.

After the resting phase, the curd mass is raised from the bottom of the cauldron and cut into two equal parts to create two wheels of cheese. Each wheel is then placed into a special mould made of plastic. A heavy object is placed on top of the cheese to apply pressure.

The final step in the process is salting, where the cheese wheels are soaked in brine, a solution of water and salt. This step can take anywhere from 12 to 25 days, depending on the saline solution and the size of the wheel. The brining process extracts moisture from the cheese and begins the aging process, which can span anywhere from nine to 20 months.

Rennet's Role in Parmesan Cheese Production

You may want to see also

Frequently asked questions

Grana Padano is made from unpasteurised, partially skimmed cows' milk.

The cows that produce the milk for Grana Padano are milked twice a day and are fed on fresh forage, hay, corn silage or preserved fodder. The milk must be sourced from the areas of production defined in the Product Specifications.

1,000 litres of milk are used to make two wheels of Grana Padano cheese.