When crafting homemade Gouda cheese, the timing of adding liquid smoke is crucial to achieving the desired smoky flavor without compromising the cheese’s texture or structure. Liquid smoke should be incorporated during the curd-making process, specifically after the milk has been heated and coagulated but before the whey is fully expelled. Adding it too early can interfere with the curdling process, while adding it too late may result in uneven flavor distribution. Ideally, mix the liquid smoke into the warm curds just before pressing, ensuring the smoky essence permeates the cheese evenly while maintaining the smooth, creamy consistency characteristic of Gouda. This method allows the smoke flavor to meld harmoniously with the cheese’s natural richness, creating a balanced and authentic smoky Gouda.

| Characteristics | Values |

|---|---|

| Timing of Addition | Liquid smoke is typically added during the cheese-making process before pressing, specifically after the curds have formed and are ready to be treated with salt. This allows the smoke flavor to infuse evenly throughout the cheese. |

| Amount to Use | Use sparingly, usually 1-2 teaspoons per 2 gallons of milk, as liquid smoke is highly concentrated. Adjust based on desired intensity. |

| Type of Liquid Smoke | Choose high-quality, natural liquid smoke without artificial additives for best flavor. Mesquite or hickory varieties are popular for Gouda. |

| Mixing Method | Stir liquid smoke into the warm whey or directly into the curds gently to ensure even distribution without overworking the curds. |

| Flavor Impact | Adds a smoky, savory dimension to Gouda, complementing its nutty and slightly sweet profile. |

| Aging Consideration | Smoked Gouda can be aged like traditional Gouda, but the smoking flavor may intensify over time. Monitor during aging for desired taste. |

| Alternative Method | For a milder smoke flavor, apply liquid smoke to the cheese surface during aging instead of mixing into the curds. |

| Storage | Smoked Gouda should be stored in a cool, humid environment, wrapped in wax or cheese paper to maintain moisture and flavor. |

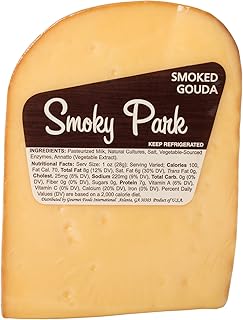

Explore related products

What You'll Learn

Timing during curd formation

Adding liquid smoke during curd formation requires precision to avoid disrupting the delicate balance of acidity and moisture in the cheese. The ideal window is after the curds have set but before they are cut, typically 10 to 15 minutes into the coagulation process. At this stage, the curd is firm enough to retain the liquid smoke without causing uneven distribution, yet still pliable enough to absorb the flavor evenly. Adding it too early risks diluting the rennet’s effectiveness, while adding it too late may result in pockets of concentrated smoke flavor. Use a dosage of 1 to 2 teaspoons per 2 gallons of milk, adjusting based on the desired intensity.

Consider the temperature of the liquid smoke before adding it, as introducing a cold additive can lower the overall vat temperature, slowing coagulation. Warm the liquid smoke to match the curd’s temperature (around 90°F for Gouda) to ensure seamless integration. Stir gently but thoroughly after addition, using a slotted spoon or whisk to avoid breaking the curds. This step is critical for achieving a uniform smoky profile throughout the cheese.

A comparative analysis of timing reveals that adding liquid smoke post-cutting yields less consistent results. Once the curds are cut, their smaller surface area limits flavor absorption, often leading to a surface-level smoke taste rather than a deep infusion. Conversely, adding it pre-coagulation can interfere with the rennet’s ability to set the milk, resulting in a softer, less structured curd. The pre-cut stage strikes the optimal balance, allowing the smoke to permeate the curd without compromising texture.

For practical implementation, monitor the curd’s texture closely. When it reaches a custard-like consistency—firm but yielding to gentle pressure—it’s ready for the liquid smoke. This typically occurs 8 to 12 minutes after adding rennet, depending on milk type and temperature. After adding the smoke, proceed with cutting and stirring as usual, ensuring the flavor integrates fully before pressing and molding. This method ensures the smoky essence becomes an integral part of the Gouda’s character, not just an afterthought.

Why You Crave Cheese: Unraveling the Science Behind Your Cheesy Obsession

You may want to see also

Liquid smoke concentration levels

Liquid smoke concentration is a critical factor when infusing homemade Gouda cheese with smoky flavor, as too little can result in an undetectable taste, while too much can overpower the cheese’s natural profile. Most liquid smoke products range from 500 to 2,000 ppm (parts per million) of smoke compounds, but for Gouda, a delicate balance is key. Start with a conservative dosage of 0.1 to 0.2% by weight of the cheese curds to avoid overwhelming the mild, nutty characteristics of Gouda. This translates to approximately 1 to 2 grams of liquid smoke per kilogram of curds, ensuring the smoke complements rather than dominates the final product.

The timing of addition also influences how the smoke flavor integrates. Adding liquid smoke during the brining stage allows for even distribution, as the curds absorb the solution more uniformly. However, if added post-pressing, the smoke flavor may concentrate unevenly, creating pockets of intensity. For a more controlled infusion, mix the liquid smoke into the brine solution at a ratio of 1 teaspoon per gallon of brine, ensuring thorough stirring before submerging the cheese. This method provides a subtle, consistent smoky note without disrupting the Gouda’s texture or moisture content.

Experimentation is essential to finding the ideal concentration for your taste preferences. Begin with the lower end of the dosage range and incrementally increase in subsequent batches. For aged Gouda, a slightly higher concentration (up to 0.3%) can enhance the deeper flavors developed during maturation. Conversely, younger Gouda benefits from a lighter touch, as its milder profile is more susceptible to overpowering. Always taste-test during the aging process to gauge the smoke’s progression and adjust future batches accordingly.

Practical tips include using high-quality, natural liquid smoke derived from hardwoods like hickory or mesquite for authenticity. Avoid artificial additives, as they can introduce off-flavors. Store liquid smoke in a cool, dark place to preserve its potency, and always measure precisely using a digital scale for consistency. Finally, document each batch’s concentration and results to refine your technique over time. Mastering liquid smoke concentration transforms homemade Gouda into a nuanced, smoky delight without sacrificing its inherent charm.

Cheese During Ash Wednesday and Lent: Religious Guidelines Explained

You may want to see also

Mixing methods for even distribution

Achieving uniform distribution of liquid smoke in homemade Gouda cheese requires precision and technique. The goal is to infuse the smoky flavor without creating pockets of intensity or leaving areas untouched. This begins with understanding the properties of liquid smoke—a water-based ingredient that can easily separate if not handled correctly. Unlike fat-soluble additives, liquid smoke disperses best when mixed into a moist, uniform base. For Gouda, this means incorporating it during the curd-making process, specifically after the curds have formed but before pressing.

One effective method is to dilute the liquid smoke in a small amount of warm water or whey before adding it to the curds. This ensures the liquid smoke is evenly distributed across the surface area. A recommended dosage is 1–2 teaspoons of liquid smoke per 2 gallons of milk, adjusted based on desired intensity. Stir the diluted mixture gently but thoroughly into the curds, ensuring every piece is coated. Overmixing can break the curds, so use a slow, deliberate motion. This step is crucial for consistency, as uneven application can result in a marbled texture or uneven flavor.

Another approach is to incorporate liquid smoke during the brining stage, though this method is less precise. Submerge the pressed cheese in a brine solution containing 1 teaspoon of liquid smoke per quart of brine. While this allows for gradual absorption, the smoky flavor may concentrate on the exterior, leaving the interior less affected. This method is better suited for mild smoky notes rather than a deep, pervasive flavor. For best results, combine both methods: add a portion during curd mixing and the remainder in brine for layered complexity.

Practical tips include using a food-grade syringe to inject diluted liquid smoke into the curds at multiple points, ensuring even saturation. Alternatively, sprinkle the diluted liquid smoke over the curds in a fine mist using a spray bottle, followed by gentle folding. Always test small batches to calibrate flavor intensity before scaling up. Remember, liquid smoke is potent—start with minimal quantities and adjust incrementally to avoid overpowering the Gouda’s natural profile. With careful technique, you can achieve a seamlessly integrated smoky flavor that enhances, rather than dominates, your homemade cheese.

Why Cheese Stops Baby Crying: Unraveling the Cheesy Mystery

You may want to see also

Explore related products

Impact on flavor development

Liquid smoke, when added to homemade Gouda cheese, can dramatically alter its flavor profile, but the timing of its introduction is critical. Adding liquid smoke during the initial stages of curd formation allows the smoky compounds to permeate the cheese matrix more evenly. This early integration ensures the smoke flavor becomes an integral part of the cheese rather than a superficial coating. For best results, mix 1–2 teaspoons of liquid smoke per 2 gallons of milk directly into the warmed milk before adding the starter culture. This method is particularly effective for cheeses aged under 3 months, as it provides a balanced, subtle smokiness without overwhelming the natural Gouda flavors.

However, adding liquid smoke post-pressing or during the aging process yields a different outcome. Surface application, such as brushing or spraying a diluted solution (1 part liquid smoke to 3 parts water) onto the cheese rind, creates a more pronounced smoky exterior while preserving the traditional Gouda interior. This technique is ideal for aged Goudas (6+ months), where the contrast between the smoky rind and the nutty, caramelized core enhances complexity. Be cautious, though: excessive application can lead to a bitter, acrid taste, so limit treatments to once every 2 weeks during aging.

The dosage of liquid smoke directly influences flavor intensity and authenticity. A light hand—0.5–1% by weight of the curd—mimics natural smoking processes, while higher concentrations (2–3%) produce a bold, barbecue-like profile. For homemade Gouda, start with 1 teaspoon per 5 pounds of curd and adjust based on desired intensity. Pairing liquid smoke with complementary ingredients, such as garlic powder or paprika, can further refine the flavor. Always taste-test small batches before scaling up to ensure the smoke enhances, rather than masks, the Gouda’s inherent sweetness and creaminess.

Temperature and humidity during aging also interact with liquid smoke to shape flavor development. Higher humidity (85–90%) softens the smoke’s edge, creating a smoother, more integrated taste, while drier conditions (70–75%) accentuate its sharpness. Monitor these variables closely, especially when experimenting with smoked Gouda recipes. For instance, a cheese aged at 55°F with high humidity will develop a milder, more rounded smoky flavor compared to one aged at 60°F with lower moisture. Understanding these dynamics allows cheesemakers to tailor the smoke’s impact to their desired outcome.

Finally, consider the aging timeline when incorporating liquid smoke. Younger Goudas (1–3 months) benefit from early addition, as the smoke melds with developing lactic and buttery notes. Older cheeses (6+ months) gain depth from surface application, as the smoke interacts with emerging crystalline structures and complex umami flavors. For a truly unique product, combine both methods: add liquid smoke during curdling and apply it to the rind midway through aging. This dual approach creates a multi-layered flavor profile, showcasing the versatility of liquid smoke in Gouda craftsmanship.

Burnt Cheese vs. Unburnt: Does Charred Dairy Cause Worse Constipation?

You may want to see also

Best practices for smoking intensity

Liquid smoke, a concentrated essence derived from condensed wood smoke, offers a shortcut to imparting smoky flavors without traditional smoking methods. When integrating it into homemade Gouda, the intensity of the smoke flavor hinges on precise timing and dosage. Adding liquid smoke too early can overpower the delicate balance of flavors developing during the cheese-making process, while adding it too late may result in uneven distribution. The ideal window is during the brining stage, after the cheese has set but before it enters the aging phase. This allows the smoke flavor to meld harmoniously with the Gouda’s natural profile.

Dosage is equally critical. For a subtle smoky undertone, start with ¼ teaspoon of liquid smoke per 2 gallons of brine. For a bolder flavor, increase to ½ teaspoon, but exercise caution—excessive liquid smoke can introduce a chemical aftertaste. Always mix the liquid smoke thoroughly into the brine to ensure even absorption. Consider the type of wood used in the liquid smoke; hickory or mesquite will impart stronger, more assertive flavors, while applewood or cherry offers a milder, sweeter note. Tailor the choice to complement the Gouda’s nutty, caramelized characteristics.

Aging plays a pivotal role in balancing smoking intensity. Younger Gouda, aged 1–3 months, benefits from lighter smoke application, as its milder flavor profile can be easily overwhelmed. Older Gouda, aged 6 months or more, can handle a more robust smoky presence, as its deeper, complex flavors stand up to the added intensity. For cheeses intended for longer aging, err on the side of moderation; the smoke flavor will concentrate as moisture evaporates during the aging process.

Practical experimentation is key to mastering smoking intensity. Begin with small batches, testing different dosages and wood types to identify your preferred flavor profile. Keep detailed notes on each trial, including the amount of liquid smoke used, the brine duration, and the resulting flavor after aging. This iterative approach allows for refinement and ensures consistency in future batches. Remember, the goal is to enhance, not dominate, the Gouda’s inherent qualities.

Finally, consider the sensory experience of the final product. A well-executed smoky Gouda should offer a layered flavor profile, where the smoke complements rather than overshadows the cheese’s natural nuttiness and creaminess. Taste-test at various aging milestones to gauge how the smoke flavor evolves. With careful attention to timing, dosage, and aging, liquid smoke can elevate homemade Gouda from excellent to extraordinary, creating a nuanced, memorable cheese.

Wisconsin Cheese Tasting Contest: Dates, Locations, and What to Expect

You may want to see also

Frequently asked questions

Add liquid smoke during the final stages of curd cooking, just before pressing, to ensure even distribution without affecting the melting or texture.

Use 1-2 teaspoons of liquid smoke per 2 gallons of milk for a subtle smoky flavor; adjust based on personal preference.

No, adding liquid smoke after pressing won’t allow it to evenly permeate the cheese, resulting in uneven flavor.

Liquid smoke does not significantly impact the aging process, but monitor the cheese closely to ensure the smoky flavor develops as desired.

It’s not recommended, as the brine is primarily for moisture control and flavor enhancement, and liquid smoke may not distribute evenly this way.