The history of 5 lb Cooper cheese sold in wooden boxes is a fascinating topic that delves into the early 20th century, when traditional packaging methods were still prevalent in the dairy industry. Cooper cheese, a popular variety known for its rich flavor and texture, was often packaged in wooden boxes to preserve its quality during transportation and storage. These wooden boxes, typically made from pine or other durable woods, were not only functional but also added a rustic charm to the product. The practice of selling 5 lb Cooper cheese in wooden boxes was most common in the 1920s to 1950s, before the widespread adoption of plastic and waxed paper packaging. This era marked a transition in food packaging, and the wooden boxes remain a nostalgic symbol of the craftsmanship and attention to detail that characterized early cheese production.

| Characteristics | Values |

|---|---|

| Product Name | 5 lb Cooper Cheese |

| Packaging Material | Wooden Boxes |

| Historical Sales Period | Mid-20th Century (exact dates vary by source) |

| Common Usage Era | 1930s to 1960s |

| Packaging Purpose | Protection, Preservation, and Branding |

| Cheese Type | Cheddar or similar hard cheese |

| Brand Association | Cooper Cheese (specific brand details limited) |

| Availability Today | Discontinued (wooden boxes no longer in use) |

| Collector's Item | Yes, wooden cheese boxes are sought after by collectors |

| Cultural Significance | Represents traditional cheese packaging and rural American heritage |

Explore related products

What You'll Learn

Historical packaging methods for Cooper cheese

The history of Cooper cheese packaging is a fascinating journey through time, reflecting both technological advancements and changing consumer preferences. One notable era in this timeline is the use of wooden boxes for 5 lb Cooper cheese, a practice that dates back to the late 19th and early 20th centuries. These wooden crates were not merely containers; they were a testament to the craftsmanship and practicality of the time. Crafted from durable woods like pine or oak, these boxes were designed to protect the cheese during transportation and storage, ensuring it arrived at its destination in optimal condition. The slatted design allowed for proper ventilation, a critical factor in preserving the cheese’s quality, as it prevented moisture buildup and mold growth.

Analyzing the shift from wooden boxes to modern packaging reveals a broader trend in food preservation and distribution. Wooden crates, while effective, were heavy and cumbersome, making them less practical as transportation methods evolved. The advent of refrigeration and the development of lighter, more cost-effective materials like waxed paper and later plastic led to the decline of wooden packaging. However, the wooden box era left a lasting legacy, influencing the design of modern cheese packaging that still prioritizes ventilation and protection. For enthusiasts looking to replicate historical methods, sourcing untreated, food-safe wood and ensuring proper sealing are key steps to recreate these traditional containers.

From a practical standpoint, understanding historical packaging methods offers valuable insights for modern cheesemakers and hobbyists alike. Wooden boxes were often lined with parchment or cheesecloth to prevent direct contact between the wood and the cheese, a technique that can still be applied today. Additionally, the size and shape of these boxes were standardized to fit into larger shipping crates, a principle that modern packaging designers continue to follow. For those interested in experimenting with traditional methods, start by selecting a 5 lb block of Cooper cheese and a wooden box with dimensions of approximately 8x8x4 inches. Ensure the wood is sanded smooth and treated with food-grade mineral oil to maintain hygiene.

Comparatively, the transition from wooden boxes to contemporary packaging highlights the trade-offs between tradition and innovation. While wooden crates offered durability and natural ventilation, modern materials like vacuum-sealed plastic provide extended shelf life and convenience. However, there’s a growing movement toward sustainable packaging, which has led to a resurgence of interest in wood-based solutions. For instance, some artisanal cheesemakers now use biodegradable wooden containers as part of their eco-friendly branding. This blend of old and new demonstrates how historical methods can inspire contemporary practices, offering both nostalgia and practicality.

In conclusion, the wooden boxes once used for 5 lb Cooper cheese are more than just relics of the past; they are a window into the evolution of food packaging. By studying these methods, we gain a deeper appreciation for the ingenuity of earlier generations and insights into how we can improve modern practices. Whether for historical recreation or sustainable innovation, the lessons from wooden cheese boxes remain relevant, reminding us that sometimes, the old ways can teach us new tricks.

Why Reblochon Cheese Remains Banned in the United States

You may want to see also

Transition from wooden boxes to modern packaging

The shift from wooden boxes to modern packaging for 5 lb Cooper cheese reflects broader trends in food preservation, transportation, and consumer expectations. Wooden boxes, once prized for their durability and natural insulation, were standard in the early to mid-20th century. These boxes were often reused or repurposed, aligning with the era’s resourcefulness. However, their bulkiness and susceptibility to moisture made them impractical as supply chains expanded and efficiency became paramount. By the 1960s, the industry began exploring alternatives that could better protect the cheese while reducing costs and waste.

Analyzing the transition reveals a combination of technological advancements and changing consumer preferences. Modern packaging materials like vacuum-sealed plastic and waxed paper emerged, offering superior moisture resistance and extended shelf life. These materials also allowed for clearer labeling, which became essential as regulatory standards for food safety and transparency evolved. For instance, the introduction of printed expiration dates and ingredient lists on packaging addressed growing consumer demand for accountability. Wooden boxes, while charming, lacked the versatility to meet these new requirements.

From a practical standpoint, the move away from wooden boxes was driven by logistical considerations. Wooden crates were heavy, increasing shipping costs and requiring more labor to handle. Modern packaging, often lightweight and stackable, streamlined distribution processes. For retailers, the shift meant easier storage and display, as well as reduced breakage during transit. Consumers also benefited from the convenience of smaller, more manageable packaging, which aligned with the rise of suburban supermarkets and self-service shopping.

Persuasively, the environmental impact of this transition is a double-edged sword. While wooden boxes were biodegradable and reusable, their production contributed to deforestation and required significant energy for manufacturing. Modern packaging, though often criticized for its reliance on plastics, has seen innovations like recyclable and compostable materials. Brands like Cooper Cheese have increasingly adopted sustainable practices, such as using plant-based films or reducing overall material usage, to mitigate their ecological footprint.

In conclusion, the transition from wooden boxes to modern packaging for 5 lb Cooper cheese was a multifaceted evolution driven by efficiency, safety, and consumer needs. While wooden boxes hold nostalgic appeal, their replacement by lighter, more functional materials marked a necessary step in the industry’s modernization. Today, the balance between tradition and innovation continues to shape packaging decisions, ensuring that products like Cooper Cheese remain both timeless and relevant.

Perfect Cheesecake Filling: Creative Mix-Ins for Irresistible Creamy Desserts

You may want to see also

Availability of 5 lb Cooper cheese in wooden boxes

The 5 lb Cooper cheese in wooden boxes was a staple in American households for much of the 20th century, particularly from the 1920s through the 1970s. During this period, wooden boxes were the primary packaging for bulk cheese, offering durability and a rustic charm that aligned with the era's aesthetic. Cooper cheese, known for its sharp flavor and firm texture, was a popular choice for families and delis alike. The wooden boxes not only protected the cheese during transport but also allowed for proper ventilation, which was crucial for maintaining its quality. This packaging method was phased out in the late 1970s as plastic and waxed paper became more cost-effective and hygienic alternatives.

For those seeking to recreate the nostalgia of 5 lb Cooper cheese in wooden boxes, it’s essential to understand the challenges of availability today. While the original wooden-boxed Cooper cheese is no longer in production, some artisanal cheesemakers and specialty shops offer similar products in wooden crates as a nod to tradition. To find these, start by exploring local farmers’ markets or cheese shops that focus on heritage or vintage-style products. Online platforms like Etsy or specialty food websites may also feature small-batch producers who replicate this classic packaging. Keep in mind that these options often come at a premium, as the wooden boxes are handcrafted and not mass-produced.

From a practical standpoint, storing cheese in wooden boxes requires specific care to ensure freshness. If you acquire a modern version of this product, ensure the wood is untreated and food-safe. Store the box in a cool, dry place, ideally at temperatures between 50°F and 55°F, to mimic traditional cellar conditions. Wrap the cheese in waxed paper or cheesecloth before placing it in the box to prevent direct contact with the wood, which can absorb moisture and affect flavor. Regularly inspect the box for mold or pests, as wood is more susceptible to these issues than modern packaging materials.

Comparatively, the shift away from wooden boxes reflects broader trends in food packaging and consumer preferences. While wooden boxes were once prized for their sustainability and reusability, modern consumers prioritize convenience and hygiene. However, the resurgence of interest in vintage and artisanal products has sparked a niche demand for wooden-boxed cheese. This trend highlights a growing appreciation for the craftsmanship and history behind traditional packaging methods. For collectors or enthusiasts, owning a wooden box of Cooper cheese—whether vintage or modern—is as much about preserving a piece of culinary history as it is about enjoying the cheese itself.

In conclusion, while the original 5 lb Cooper cheese in wooden boxes is no longer widely available, its legacy lives on through artisanal recreations and a renewed interest in heritage packaging. For those willing to invest time and effort, finding or creating this classic product can be a rewarding experience. Whether for personal enjoyment or as a conversation piece, the wooden-boxed Cooper cheese remains a timeless symbol of American culinary tradition.

Refrigerate or Not? The Truth About Individually Wrapped Cheese Sticks

You may want to see also

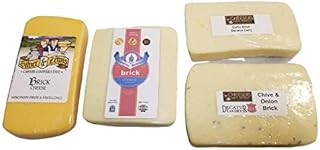

Explore related products

Timeline of wooden box usage for cheese

The use of wooden boxes for cheese packaging has a rich history, with roots tracing back to the early days of cheese production. While specific records for 5 lb Cooper cheese in wooden boxes are scarce, the broader timeline of wooden box usage for cheese offers valuable insights. Wooden boxes were favored for their durability, breathability, and ability to protect cheese during transport. In the 18th and 19th centuries, artisanal cheesemakers in Europe and the United States relied on wooden crates and boxes to store and ship cheese, often lined with waxed paper or cloth to maintain freshness. This practice was particularly common for hard and semi-hard cheeses, which required aging and needed a sturdy container to withstand handling.

By the early 20th century, wooden boxes became standardized for specific cheese weights, including 5-pound blocks. Cooper cheese, a term often associated with cheddar or similar varieties, would have been packaged in these boxes during this era. The boxes were typically made from pine or spruce, chosen for their lightweight yet robust nature. Labels were affixed to the wood, providing details like the cheese type, weight, and producer. This period marked the peak of wooden box usage, as they were seen as both functional and cost-effective before the advent of modern packaging materials.

The decline of wooden boxes began in the mid-20th century with the introduction of plastic and waxed cardboard, which offered cheaper production costs and greater moisture resistance. However, wooden boxes persisted in niche markets, particularly for premium or traditionally crafted cheeses. Today, wooden boxes are often used for artisanal or specialty cheeses, where they add a rustic, nostalgic appeal. While 5 lb Cooper cheese in wooden boxes is no longer a common sight, it remains a symbol of the craftsmanship and tradition of early cheese production.

For those interested in replicating historical cheese storage, wooden boxes can still be sourced from specialty suppliers or crafted by hand. Ensure the wood is untreated and food-safe, and line the box with parchment or cheese paper to prevent direct contact. While modern packaging has largely replaced wooden boxes, their legacy endures as a testament to the ingenuity of early cheesemakers. Understanding this timeline not only sheds light on the question of when 5 lb Cooper cheese was sold in wooden boxes but also highlights the evolution of cheese packaging as a reflection of technological and cultural changes.

Mastering Transformice: Proven Strategies to Earn Tons of Cheese Fast

You may want to see also

Reasons for discontinuing wooden cheese boxes

The shift away from wooden cheese boxes, particularly for products like 5 lb Cooper cheese, reflects broader changes in consumer preferences, manufacturing efficiency, and regulatory standards. One primary reason for discontinuing wooden boxes was the rise of plastic and waxed paper alternatives, which offered greater moisture resistance and extended shelf life. Wooden boxes, while charming and traditional, were prone to absorbing odors and moisture, potentially compromising the cheese’s quality over time. For instance, studies showed that plastic packaging could reduce mold growth by up to 40% compared to wood, making it a more reliable choice for retailers and consumers alike.

Another critical factor was the logistical challenge of wooden packaging. Wooden boxes were heavier and bulkier than modern materials, increasing shipping costs and storage requirements. For a 5 lb block of cheese, the added weight of the wooden box could account for an additional 1-2 lbs, significantly impacting transportation efficiency. Retailers began favoring lightweight, stackable packaging that maximized shelf space and minimized handling difficulties. This shift was particularly evident in the mid-20th century, when supermarkets prioritized streamlined operations over nostalgic packaging.

Health and safety regulations also played a pivotal role in the decline of wooden cheese boxes. Wooden surfaces, even when treated, posed a higher risk of bacterial contamination compared to non-porous materials like plastic or metal. The FDA and other regulatory bodies began enforcing stricter guidelines on food packaging, particularly for products like cheese that are susceptible to bacterial growth. Wooden boxes, despite their natural appeal, often required extensive treatment with chemicals to meet these standards, which raised concerns about chemical leaching into the cheese.

Finally, consumer demand for convenience and sustainability influenced the discontinuation of wooden boxes. While wooden packaging was biodegradable, its production often involved deforestation and resource-intensive manufacturing processes. Modern consumers increasingly sought eco-friendly alternatives that balanced sustainability with practicality. For example, recyclable plastic and compostable paper packaging emerged as viable options, offering the environmental benefits of wood without its drawbacks. This shift was accelerated by marketing campaigns highlighting the reduced carbon footprint of newer materials.

In summary, the discontinuation of wooden cheese boxes for products like 5 lb Cooper cheese was driven by a combination of practical, regulatory, and consumer-driven factors. From improved food safety and logistical efficiency to shifting environmental priorities, the transition to modern packaging materials marked a significant evolution in the cheese industry. While wooden boxes remain a nostalgic symbol of traditional craftsmanship, their decline underscores the ongoing balance between preserving heritage and embracing innovation.

Repotting a Cheese Plant with Moss Pole: A Step-by-Step Guide

You may want to see also

Frequently asked questions

5 lb Cooper cheese was historically sold in wooden boxes during the early to mid-20th century, with the practice becoming widespread in the 1920s and 1930s.

Wooden boxes were used for 5 lb Cooper cheese because they provided sturdy protection during transportation and storage, while also allowing the cheese to breathe, which helped maintain its quality.

The use of wooden boxes for 5 lb Cooper cheese declined in the 1950s and 1960s as more cost-effective and hygienic packaging materials, such as waxed paper and plastic, became popular.

Yes, vintage wooden boxes for 5 lb Cooper cheese are sought after by collectors and enthusiasts of dairy memorabilia, often valued for their historical significance and rustic charm.