There are many reasons why your goat cheese mixture might not be curdling. One of the most common reasons is that the milk was heated to too high a temperature, which can cause the proteins in the milk to be destroyed or damaged, preventing curdling. Other factors that can affect curdling include the type of milk, the acidity of the mixture, and the presence of other ingredients such as salt or colostrum. In some cases, it may be necessary to adjust the temperature, acidity, or ingredients in order to achieve the desired curdling effect.

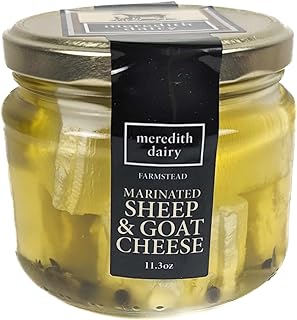

Explore related products

What You'll Learn

The mixture was heated too much

If your goat cheese mixture isn't curdling, it's possible that it was heated too much. Overheating can cause the proteins in the milk to become too tough and lose their ability to set properly. This can happen if the milk is heated too quickly or if it boils.

To prevent this from happening in the future, heat the milk slowly and stir it constantly. Make sure that the milk You may want to see also If your goat cheese mixture isn't curdling, it could be because you used the wrong type of milk. Goat's milk is commonly used to make goat cheese, and it can be raw or pasteurized. If you're using raw milk, you can simply leave it out on the counter to ripen, and the natural bacteria in the milk will produce lactic acid, causing the milk to curdle. However, if you're using store-bought milk, it may have been ultra-pasteurized, which involves heating the milk to a higher temperature, damaging or destroying the milk proteins and preventing curdling. Temperature control is crucial when making cheese. The ideal approach is to start at the desired temperature and maintain it throughout the process. Typically, rennet is added when the milk is between 20 and 40 degrees Celsius. Above 20 degrees, coagulation increases until it reaches its maximum at 40-42 degrees Celsius. Beyond this temperature, coagulation becomes impossible. Additionally, the type of milk used can impact the curdling process. For example, some recipes call for buttermilk or yogurt, which can affect the taste and texture of the final product. Buttermilk will make the cheese slightly more sour, while yogurt will result in a thicker consistency. If you're using raw milk, you might need to add an acid to induce curdling. Lemon juice, vinegar, or citric acid are common choices, but be cautious not to over-acidify the mixture, as this can prevent curds from forming. Finally, it's worth noting that the addition of salt can also impact curdling. In most recipes, salt is added after draining the curds to draw out the whey. Adding salt directly to the milk before heating may interfere with the curdling process. You may want to see also If your goat cheese mixture is not curdling, it could be because the milk was over-acidified. Over-acidification can prevent milk from curdling and forming curds. This can happen when too much acid is added to the milk, not allowing the curds to come together. To prevent over-acidification, it is important to add the right amount of acid, such as lemon juice or vinegar, to the milk. The amount of acid needed will depend on the volume of milk being used. For example, for every quart of milk, you can add a quarter cup of lemon juice or half a cup of vinegar to induce curdling. It is also important to note that the milk should be heated to the right temperature before adding the acid. The ideal temperature range for coagulation is between 20 and 40 degrees Celsius, with the maximum coagulation occurring at 40-42 degrees Celsius. Above 65 degrees Celsius, coagulation becomes impossible. If you suspect that your milk was over-acidified, you can try to salvage your cheese mixture by adding more milk to dilute the excess acid. You can then gently reheat the mixture to the desired temperature range and try to induce curdling again. Additionally, you can let the mixture sit for a while to allow the curds to form without stirring, as over-stirring can cause the curds to shatter. It is worth noting that acid-curdled cheese tends to have a less flavourful profile compared to cheese made with cultures and rennet. Acid-curdled cheese lacks the cultures necessary to produce cheese flavours, and it is not typically brined to introduce salt. However, it can still be used as a meat substitute in recipes, adding a crispy texture when pan-fried. You may want to see also Rennet is an essential tool in making cheese from milk. It is a coagulating enzyme that causes the protein in milk, which is normally dispersed in the liquid, to come together and form a matrix, which we call "curd". Rennet is usually derived from the fourth stomach, or abomasum, of an unweaned calf, kid, or lamb. In the stomachs of these young animals, chymosin essentially turns milk into a soft cheese to enable slower digestion and better absorption of nutrients. There are other sources of rennet, however, that are suitable for vegetarians. Vegetable rennet can be sourced from plants such as cardoon thistle, butterwort, artichoke, nettles, safflower, melon, yellow bedstraw, and fig leaves. To derive the coagulating enzyme, these plants are steeped in water to make a "tea", which is then added to the milk. Rennet can also be derived from two types of mould that naturally create chymosin. The role of rennet in cheese-making is to transform liquid milk into solid cheese. When rennet is stirred into milk, it causes the four different kinds of casein molecules in milk to attach to each other, forming protein "teams" called micelles that float throughout the milk. The molecules of one type of casein, kappa casein, protrude like fine hairs from the surface of each micelle sphere and attract water molecules. Without this attraction, the micelles would separate from the liquid matter as solids. In other words, kappa casein makes milk proteins drinkable. When making goat cheese, the milk is heated to a certain temperature, and then a coagulating agent is added to curdle the milk. Traditional feta, for example, is not an acid-coagulated cheese, and requires rennet. However, there are numerous cheeses that are strictly acid-coagulated and require only citric acid or vinegar and no rennet. You may want to see also One of the primary reasons why your goat cheese mixture may not be curdling is due to over-stirring. When you stir the mixture too much, you can inadvertently prevent the curds from forming properly. This is because excessive stirring can break down the delicate protein structures that are essential for the curdling process. The curdling of goat cheese relies on the precise interaction between the acidic component (usually lemon juice or vinegar) and the milk proteins. These proteins, primarily casein and whey, need to coagulate and separate from the whey to form the desired curds. However, when you stir the mixture too vigorously or too frequently, you risk disrupting this coagulation process. Ideally, after adding the acidic agent to the milk, gentle and slow stirring is recommended to encourage the formation of curds. Overly vigorous stirring can break apart the curds as they start to form, resulting in a smoother, less-chunky mixture that never quite achieves the desired curdled texture. It's important to remember that the curdling process is a delicate balance of science and art, and sometimes less intervention yields better results. To avoid this issue in the future, practice patience and stir your goat cheese mixture gently and infrequently. Allow the mixture to sit undisturbed for several minutes after initial stirring to give the curds a chance to form. If needed, you can then gently stir again, but always be mindful that too much intervention can hinder the natural curdling process. Remember, when it comes to stirring, sometimes less is more in the world of cheesemaking! You may want to see also It could be that you added salt to the milk before heating it up. Try adding the salt after draining the curds. You may have heated the milk too much. Try heating the milk to 180-185°F (82.2-85°C) and adding an acid like lemon juice or vinegar. The milk may be ultrapasteurized, which makes it impossible for curdling to occur. Try using milk from a local farm or Whole Foods. You may have added too much milk, making the mixture not acidic enough. Try adding more acid like lemon juice or vinegar. You may have added the rennet when the milk was too hot. Rennet typically stops being usefully active around 130°F (54.4°C). Try adding the rennet when the milk is cooler.Goat Cheese and Feta: What's the Difference?

The wrong type of milk was used

Beetroot and Goat Cheese Ravioli: The Perfect Pairing Ideas

The milk was over-acidified

Goat Cheese Brands: The Creamy, Dreamy Top Picks

Explore related products

The mixture needed rennet

Goat Cheese Delicacies: Culinary Exploration and Creative Recipes

The mixture was stirred too much

Goat or Not: Halloumi Cheese's Origin Mystery

Frequently asked questions