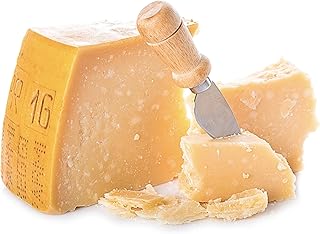

Grana Padano is a traditional Italian cheese, originating in the Po Valley. It is a semi-fat, hard cheese produced with cow's milk from two daily milkings. The wheels of Grana Padano are cylindrical, with slightly convex or almost straight sides and flat faces, weighing between 24 and 40 kg. During the maturation process, which can last up to 16 months or more, the wheels are regularly brushed, cleaned, and turned to eliminate surface contamination and mould. The outermost surface of the rind is carefully cleaned before consumption. Grana Padano cheese wheels are also subjected to stringent monitoring, with technicians examining them every 15 days during the first nine months of maturation.

Explore related products

What You'll Learn

- Cleaning frequency: Grana Padano wheels are brushed and turned every 15 days for the first nine months

- Cleaning purpose: Regular brushing prevents mould and eliminates surface contamination

- Rind safety: The rind is edible once the outermost surface has been carefully cleaned

- Rind function: The hardening rind protects the cheese during maturation

- Testing: Strict testing ensures the elimination of pathogens in the raw milk used

Cleaning frequency: Grana Padano wheels are brushed and turned every 15 days for the first nine months

Grana Padano is a traditional, pasteurised, hard cheese from Italy, specifically the Po Valley of Northern Italy. It is made from cow's milk, and its smooth, natural rind is extremely hard and thick. The rind is an integral part of the cheese and is edible once the outermost surface has been carefully cleaned.

During the maturation process, which can last from 12 to 14 months and beyond, the wheels are regularly brushed, cleaned, and turned. This process helps to reduce humidity and eliminate any surface contamination by moulds present in the environment, which could form on the surface as a result of natural exudation.

In the first nine months, the wheels are brushed and turned every 15 days. This frequent cleaning and turning helps to maintain the excellence of the cheese, ensuring that it develops the right texture and flavour. After this initial period, the wheels are examined by technicians and an independent accreditation body to ensure they meet the required standards.

The cleaning and turning of Grana Padano wheels at regular intervals are crucial steps in the production process. It ensures the cheese matures evenly and helps develop its distinctive flavour and texture, making it one of the most popular PDO cheeses in the world.

Sargento Cheese Recall: What You Need to Know

You may want to see also

Cleaning purpose: Regular brushing prevents mould and eliminates surface contamination

Grana Padano cheese is a traditional Italian cheese, originating in the Po Valley. It is a semi-fat hard cheese made with cow's milk from two daily milkings. The wheels are left to mature in dedicated warehouses with controlled temperature and humidity.

To preserve the cheese, the wheels are regularly brushed, cleaned, and turned. This process prevents mould and eliminates surface contamination. The brushing and turning of the wheels occur every 15 days during the first nine months of maturation. This also favours the loss of humidity.

The rind of the cheese hardens during maturation, acting as a barrier to protect the cheese inside. The outermost surface of the rind is carefully cleaned and is perfectly edible. The rind does not undergo any chemical treatments and is not covered by any colouring or plastic material.

Grana Padano cheese is typically sold in three different ripening stages: "Grana Padano" (9 to 16 months), "Grana Padano oltre 16 mesi" (over 16 months), and "Grana Padano Riserva" (over 20 months). The cheese is known for its thick, golden, oiled crust, weighing between 24 and 40 kg.

Removing Wax from Cheese: Quick and Easy Methods

You may want to see also

Rind safety: The rind is edible once the outermost surface has been carefully cleaned

Grana Padano PDO cheese is made from cow's milk sourced from the Po Valley in Northern Italy. The milk is heated, after which calories and rennet are added. The curd is then broken, purged, and cooked, before being divided into two forms that are salted and immersed in brine for 25-30 days. The forms are then seasoned for 12 to 14 months or longer. During this time, the rind hardens to protect the cheese inside. The wheels are stored in dedicated warehouses with controlled temperature and humidity.

The Grana Padano PDO rind is an integral part of the cheese and is perfectly edible. However, it is important to carefully clean the outermost surface before consumption, similar to how one would clean the peel of an apple. The rind does not undergo any chemical treatments and is free from artificial colouring or plastic coverings.

To maintain the quality of the cheese, the wheels are regularly brushed, cleaned, and turned during the maturation process. This practice not only facilitates the loss of humidity but also prevents surface contamination by environmental moulds. The brushing and turning occur once every 15 days during the first nine months, and the wheels are examined by technicians and an independent body.

The Grana Padano PDO Production Specifications govern the entire production process, ensuring the cheese's authenticity and maintaining its average nutritional value and calories. This stringent monitoring guarantees the elimination of any potential pathogens present in the raw milk, ensuring the safety of the final product.

Cheese Escape: Getting the Last Cheese

You may want to see also

Explore related products

Rind function: The hardening rind protects the cheese during maturation

Grana Padano is a hard, gourmet Italian cheese, made from cow's milk from the Po River Valley in Northern Italy. It is a popular PDO cheese, with around 150 factories producing an estimated 76,724 tons of this cheese annually. The cheese is made following a traditional process created by monks in 1000 AD.

The rind of a Grana Padano cheese wheel is an integral part of the cheese. The thin, pale yellow rind hardens during the maturation process, acting as a protective barrier for the cheese inside. The hardening of the rind is a natural process and is crucial to the cheese's preservation. The wheels are stored in temperature- and humidity-controlled warehouses, where they are regularly brushed, cleaned, and turned to prevent mould and eliminate surface contamination.

The maturation process for Grana Padano typically lasts between 12 and 14 months, and sometimes longer. During this time, the rind continues to harden, providing an essential protective shell. The hardening rind safeguards the cheese from external agents and environmental contaminants, ensuring the cheese remains safe for consumption.

The Grana Padano rind is perfectly edible after the outermost surface has been carefully cleaned, similar to how one would consume an apple after removing the peel's outer layer. The rind does not undergo any chemical treatments and is free from artificial colouring or plastic coatings, adhering to the Production Specification Rules.

In summary, the hardening rind of a Grana Padano cheese wheel serves as a protective barrier, safeguarding the cheese during its maturation. The rind's hardening process, combined with proper cleaning and storage techniques, ensures the cheese remains uncontaminated and safe to consume.

Eradicating Knob Cheese: Tips and Tricks for Success

You may want to see also

Testing: Strict testing ensures the elimination of pathogens in the raw milk used

Grana Padano cheese is made from cow's milk sourced from the Po River Valley in Northern Italy. The cheese is known for its thick, natural rind, which forms a protective barrier around the cheese during the maturation process. The rind is perfectly edible once the outermost surface has been carefully cleaned.

Grana Padano is classified as a Protected Designation of Origin (PDO) cheese, which means that it undergoes strict testing to ensure food safety. The production process, as outlined in the Production Specification Rules, guarantees the elimination of any pathogens potentially present in the raw milk used. This is achieved through the combined effect of temperature and pH control during the production process, as well as natural lactic fermentation, which continues for several hours.

The use of raw milk in cheese production can introduce a variety of disease-causing pathogens. However, specific testing has confirmed the safety of Grana Padano PDO cheese, demonstrating the effective elimination of any potential pathogens. This is further supported by the proper application of the HACCP (Hazard Analysis and Critical Control Points) system, which ensures food safety through process control. While the HACCP system may reduce the probability of raw milk contamination, it is important to note that it does not guarantee the complete absence of pathogens.

To ensure the highest standards, Grana Padano cheese undergoes stringent monitoring at every production stage. During the first nine months, the wheels are brushed and turned every 15 days to facilitate humidity loss and prevent surface contamination by moulds. This process is crucial in maintaining the quality and safety of the cheese. Additionally, the wheels are examined by both the consortium's technicians and an independent accreditation body.

In summary, strict testing and adherence to production specifications ensure the elimination of pathogens in the raw milk used for Grana Padano cheese. The maturation process, careful cleaning, and application of safety protocols contribute to the cheese's safety and edibility, making it a renowned and trusted product worldwide.

The Art of Flavoring Cheese: A Culinary Adventure

You may want to see also

Frequently asked questions

Yes, the wheels are brushed, cleaned, and turned regularly during the maturation process. This helps eliminate surface moulds and other contaminants.

The wheels are left to mature in warehouses with controlled temperatures and humidity for at least 12 months. During this time, the rind hardens to protect the cheese, and it is brushed and turned every 15 days.

The Grana Padano rind is a natural, thin, pale yellow layer that forms around the cheese. It is perfectly edible once the outermost surface has been carefully cleaned. The rind acts as a protective barrier against external agents that could compromise the cheese.