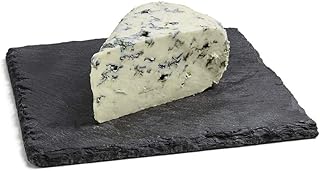

Blue cheese is a generic term for any cheese made from cow, goat, or sheep's milk that has been ripened with cultures of the mould Penicillium roqueforti. The greenish-blue veins in blue cheese are created by piercing the cheese with stainless steel rods to allow oxygen to circulate and encourage the growth of mould. Blue cheese is typically aged in temperature-controlled environments and can vary in flavour, colour, and consistency.

| Characteristics | Values |

|---|---|

| What is blue cheese? | A generic term for any cheese made from cow, goat, or sheep's milk that's been ripened with cultures of the mold penicillium. |

| How is it made? | Raw milk is pasteurized and a starter culture is added to convert the lactose in the milk to lactic acid (a process called acidification), which makes the milk morph from liquid to solid. |

| How does it get its blue color? | The penicillium mold gives it its distinctive blue veins. |

| What does it taste like? | Blue cheese varies in flavor from mild to strong and from slightly sweet to salty or sharp. |

| What does it smell like? | Blue cheese has a distinctive pungent aroma. |

| What is its texture? | Blue cheese varies in texture from liquid to hard, crumbly to creamy. |

| Where does it come from? | Blue cheese likely originated by accident when cheese was stored in caves with naturally controlled temperature and moisture levels, which created favorable environments for the growth of harmless mold. |

| What are some popular varieties? | Roquefort, Gorgonzola, Stilton, and Danish blue. |

Explore related products

What You'll Learn

Blue cheese is made from cow, goat or sheep's milk

Blue cheese is a generic term for any cheese made from cow's, goat's, or sheep's milk that has been ripened with cultures of the mould Penicillium roqueforti. The mould creates the distinctive blue-green spots or veins throughout the cheese paste. The final product is characterised by green, grey, blue, or dark veins or spots of mould.

Blue cheese is believed to have been discovered by accident when cheeses were stored in caves with naturally controlled temperatures and moisture levels, which created a favourable environment for the growth of harmless mould. The most well-known variety of blue cheese is Roquefort, which is made from sheep's milk and aged in natural caves in the south of France. It is considered a delicacy and is known for its bold, nuanced, creamy, and aromatic flavour. Other popular varieties of blue cheese include Gorgonzola, Stilton, and Danish blue.

Gorgonzola, originating from Italy, is made from cow's milk and has a creamy texture with a slightly sharp taste. Stilton, a classic English blue cheese, is also made from cow's milk and is known for its crumbly texture and mellow flavour. Danish blue, as the name suggests, is made in Denmark from cow's milk. Saint Agur, another creamy blue cheese, is made from a combination of milk from local Montbéliarde cows and cream. It is hand-salted and pierced with needles to activate the growth of its blue veins.

The process of making blue cheese involves pasteurising raw milk and adding a starter culture to convert the lactose in the milk to lactic acid, which solidifies the milk. Rennet is then added to coagulate the milk, and the curds are cut to release the whey. The curds are formed into wheels and aged for 60-90 days. During the early stages of ageing, the cheese is spiked with stainless steel rods to allow oxygen circulation and encourage the growth of mould, creating the unique blue veins. The mould also contributes to the development of the cheese's signature flavour and softer texture.

Blue Cheese and Pesto: A Match Made in Heaven?

You may want to see also

It gets its blue-green spots from edible moulds

Blue cheese is made from cow's, goat's, or sheep's milk. It gets its blue-green spots from edible moulds, specifically, cultures of the mould Penicillium roqueforti. In the first phase of production, a Penicillium roqueforti inoculum is prepared using a freeze-dried Penicillium roqueforti culture. This mould is washed from a pure culture agar plate and then frozen. The freeze-drying process involves evaporating the water from the frozen state without transitioning through the liquid state (sublimation). This process ensures the culture retains its value and is reactivated when water is added.

The blue-green veins in blue cheese develop naturally during the maturation process. To encourage the growth of mould, the cheese is spiked with stainless steel rods to allow oxygen to circulate. This process also softens the texture of the cheese and helps create its distinctive flavour and aroma. The flavour and odour of blue cheese are due to the particular mixture of methyl ketones such as 2-heptanone, 2-pentanone, and 2-nonanone, which are metabolic products of Penicillium roqueforti.

Blue cheese was likely discovered by accident when cheeses were stored in caves with naturally controlled temperatures and moisture levels, creating a favourable environment for harmless varieties of mould to grow. Today, blue cheeses are typically aged in temperature-controlled environments.

Blue Cheese and Acid Reflux: A Risky Combination?

You may want to see also

Penicillium roqueforti is the mould that gives it its distinctive blue veins

Blue cheese is made with the addition of cultures of edible moulds, which create blue-green spots or veins throughout the cheese. Penicillium roqueforti is the mould that gives it its distinctive blue veins. It is a common saprotrophic fungus in the genus Penicillium, which can be isolated from soil, decaying organic matter, and plants. It is particularly well-adapted to the conditions encountered during blue cheese manufacture, including low oxygen levels and temperatures.

Penicillium roqueforti is responsible for the greenish-blue mouldy aspect of blue cheese. It is first prepared as an inoculum before the actual production of blue cheese. This involves the use of a freeze-dried Penicillium roqueforti culture. The mould is washed from a pure culture agar plate, which is then frozen and freeze-dried. This process retains the value of the culture and is activated when water is added. Salt, sugar, or both are then added to autoclaved, homogenized milk via a sterile solution, which is then inoculated with Penicillium roqueforti.

The inoculated solution is then incubated for three to four days at 21–25 °C (70–77 °F). More salt and/or sugar is added, and then aerobic incubation is continued for an additional one to two days. Alternatively, sterilized, homogenized milk and reconstituted non-fat solids or whey solids are mixed with sterile salt to create a fermentation medium, to which a spore-rich Penicillium roqueforti culture is added.

During the ripening period, the temperature and humidity in the room are monitored to ensure the cheese does not spoil or lose its optimal flavour and texture. The ripening temperature is usually around eight to ten degrees Celsius with a relative humidity of 85–95%cheese loaves are punctured to create small openings to allow air to penetrate and support the growth of the aerobic Penicillium roqueforti cultures, thus encouraging the formation of blue veins.

Blue Cheese and Potato: A Perfect Pairing?

You may want to see also

Explore related products

Blue cheese is believed to have been discovered by accident

Blue cheese is made with the addition of cultures of edible moulds, which create blue-green spots or veins throughout the cheese. It is believed that blue cheese was discovered by accident when cheeses were stored in caves with naturally controlled temperatures and moisture levels, which happened to be favourable environments for the growth of harmless moulds.

Roquefort, a type of blue cheese, is considered one of the oldest blue cheeses and is considered a delicacy. It is produced from sheep's milk and aged in the limestone cliffs in the south of France, specifically in the village of Roquefort-sur-Soulzon. The flavour of Roquefort comes from the use of unpasteurized sheep's milk, inoculation with Penicillium roqueforti, and the special conditions of the natural caves in which they are ripened.

The process of making blue cheese involves preparing a Penicillium roqueforti inoculum before the actual production of the cheese. This is done by washing the Penicillium roqueforti from a pure culture agar plate, which is then frozen and freeze-dried. Salt, sugar, or both are then added to autoclaved, homogenized milk via a sterile solution, which is then inoculated with Penicillium roqueforti.

After the inoculation, the curds are formed and then pressed into moulds to form cheese loaves with a relatively open texture. The whey is then drained for 10-48 hours, and the moulds are frequently inverted to promote this process. Salt is then added to provide flavour and act as a preservative. The final step is ripening the cheese by ageing it in a temperature- and humidity-controlled environment for 60-90 days. During this ripening period, the mould cultures and needling contribute largely to the flavour and texture of the blue cheese.

Blue Cheese Crumbles: Sodium Content and Health Concerns

You may want to see also

It's often characterised by a crumbly texture and pungent aroma

Blue cheese is a generic term for cheese produced with cow's milk, sheep's milk, or goat's milk. It is often characterised by a crumbly texture and pungent aroma.

The distinctive crumbly texture of blue cheese is achieved through the specific steps taken during the cheese-making process to encourage the growth of the blue mold. First, the milk is curdled using rennet or other coagulating agents, and then the curds are cut and separated from the whey. After the curds are formed, they are mixed with Penicillium roqueforti, which is responsible for the growth of the greenish-blue moldy veins that run throughout the cheese. The curds are not tightly packed during the pressing process, which allows for air gaps to form between them. The presence of these air gaps means that, after piercing, the mold can also grow in between the curds.

The pungent aroma of blue cheese is also a result of the presence of mold. The distinct smell is caused by the metabolic product of Penicillium roqueforti, which is responsible for the blue veins in the cheese. The mold further breaks down fatty acids to form ketones, which contribute to the richer flavour and aroma of blue cheese. The type of milk used in the production of blue cheese can also impact its aroma—for example, Roquefort blue cheese, which originates from the village of Roquefort-sur-Soulzon in France, is made with unpasteurized sheep's milk, which contributes to its unique flavour and odour.

The crumbly texture and pungent aroma of blue cheese are not only dependent on the type of mold used and the type of milk used but also on the conditions under which the cheese is stored. For example, blue cheeses are typically aged in temperature-controlled environments, and the way the mold develops can create different hues, either blue, green, or even dark spots of mold. As long as the cheese is maintained at an adequate temperature and humidity while in maturation rooms or stored in adequate packaging in the fridge, the mold in blue cheese is safe to eat.

Best Places to Buy Roka Blue Cheese Spread

You may want to see also

Frequently asked questions

Blue cheese is a generic term for any cheese made from cow, goat, or sheep's milk that has been ripened with cultures of the mould penicillium.

Blue cheese is made from pasteurised or unpasteurised cow's, goat's or sheep's milk.

Blue cheese can vary in flavour from mild to strong, salty to sharp, and from slightly sweet to salty or nutty.

Blue cheeses can vary in colour from pale to dark and in consistency from liquid to hard. They are characterised by their blue, green, grey, or dark veins or spots of mould.

Blue cheese is believed to have been discovered by accident when cheeses were stored in caves with naturally controlled temperatures and moisture levels, which created favourable environments for the growth of harmless mould.