Brick cheese is a medium-soft cheese that is made in the form of a large rectangular or brick shape. It is called brick cheese because it was originally formed using actual bricks to mould the shape. The cheese is made by heating raw milk to 162°F, which pasteurizes it, and then cooling it to around 90°F before pumping it into open steel vats. The cheese originates from Wisconsin, USA, and was first made by John Jossia in 1877.

| Characteristics | Values |

|---|---|

| Place of origin | Wisconsin, United States |

| Date of origin | 1877 |

| Creator | John Jossi, a Swiss-born American cheese maker |

| Cheese type | Medium-soft, semi-hard |

| Texture | Slightly softer |

| Colour | Pale yellow to white with an orange rind |

| Flavour | Sweet and mild when young, strong and nutty when aged |

| Use | Melts well, suitable for sandwiches, grilled cheese sandwiches, burgers, polenta, mac and cheese, and pizza |

| Shaping | Originally pressed with clay-fired bricks |

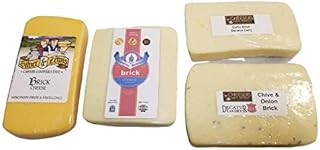

Explore related products

What You'll Learn

Brick cheese is pressed with bricks to form its brick shape

Brick cheese is a medium-soft cheese made in a brick-shaped form. It is pressed with bricks to form its brick shape and is also called brick cheese because of this traditional process. The cheese curds are cooked for about 40 minutes and then cut into cubes with wire blades. They are then placed in perforated rectangular moulds, which are pressed to squeeze out the whey. The pressing was traditionally done with bricks, and the cheese was weighted down with bricks before being placed in a brine solution.

The process of making brick cheese was developed by John Jossi, a Swiss-born American cheesemaker, in 1877. Jossi settled in Wisconsin and began producing brick cheese at a newly built plant. He envisioned a cheese with drier curds than those used in Limburger cheese, which he had previously produced. Jossi's success with brick cheese led to the spread of the recipe, and he taught it to a dozen other Wisconsin dairies. Today, there is only one place left that makes traditional brick cheese: Widmer's Cheese Cellars in Wisconsin, run by the third generation of the Widmer family.

Brick cheese has a sweet and mild flavour when young, but as it ages, it becomes stronger and more pungent, with a nuttier taste and a stronger smell. It ranges in colour from ivory to pale yellow, with an orange rind. It is semi-hard with an open texture and sometimes features small holes. The cheese is typically wrapped in foil or wax paper to protect it and contain its aroma, which can be quite strong.

Brick cheese is a popular choice for pizza, particularly Detroit-style pizza, and is also used in grilled cheese sandwiches, macaroni and cheese, and potatoes gratin. It pairs well with pickles and is a good choice for adding flavour to burgers. When it comes to wine, brick cheese goes well with fruity red wines like Beaujolais or Syrah.

The Truth About Shredded Cheese Shelf Life

You may want to see also

The cheese was first made in Wisconsin in 1877

Brick cheese was first made in Wisconsin in 1877 by John Jossi, a Swiss-born American cheesemaker. The name "brick" comes from the original cheese-making process, in which artisans used bricks to press the moisture out of the cheese and form its distinctive brick shape.

Jossi settled in Richwood, in southwest Wisconsin, and it was here that he invented brick cheese. He envisioned a cheese made with curd that was drier than that used for the Limburger he had produced in the factories he worked in. He came up with the idea of using bricks to press the cheese, creating the shape that we know today.

Jossi's success with brick cheese led to the spread of the recipe across Wisconsin. He taught the recipe to a dozen other Wisconsin dairies, and today, brick cheese is considered an American original. It is often served in the Midwest with corn polenta, where it is thinly sliced and melted underneath the polenta and then topped with tomato sauce.

Brick cheese is made by heating raw milk to 162°F, which pasteurizes it, and then cooling it to around 90°F before pumping it into open steel vats. A starter culture of bacteria is then added, which starts the process of fermentation. The curds are cooked for about 40 minutes to help firm the cheese and intensify its acidity, then cut into cubes and placed into perforated rectangular molds. These molds are then pressed to squeeze out the whey, traditionally with bricks. After pressing overnight, the bricks are placed in a brine solution for another 12 hours before being transferred to an aging room.

Gruyere Alternatives: Cheeses You Can Substitute

You may want to see also

It's made from raw milk, bacteria, brine, and rennet

Brick cheese is a medium-soft cheese made in a large rectangular or brick shape. It is made from raw milk, bacteria, brine, and rennet. The cheese was originally produced in Wisconsin in 1877 by John Jossi, a Swiss-American cheesemaker.

The process of making brick cheese involves heating raw milk to 162°F, pasteurising it, and then cooling it to around 90°F. The milk is then pumped into open steel vats, and a starter culture of bacteria is added to begin fermentation. This bacteria consumes lactose and produces lactic acid.

Next, rennet is added to the mixture. Rennet is a substance that contains enzymes that trigger the curdling of milk proteins, separating them from the liquid whey. The curds are then cooked for about 40 minutes to firm the cheese and intensify its acidity. After cooking, the curds are cut into cubes with wire blades.

The curds are then placed into perforated rectangular moulds and pressed to remove excess whey. Traditionally, this pressing was done using bricks, which is how the cheese got its name. The bricks of cheese are then soaked in a brine solution for 12 hours before being transferred to an ageing room.

In the ageing room, the bricks of cheese are washed with a solution of whey and brine containing the bacterium Brevibacterium linens. This process, called smear-ripening, gives the cheese its distinctive aroma. The cheese is then transferred to a cold ageing room, where it spends at least one more week before being ready for consumption.

Cheese Tamales: Choosing the Perfect Cheese

You may want to see also

Explore related products

It's best known as the cheese for Detroit-style pizza

Brick cheese is a type of cheese that may be best known for its use in Detroit-style pizza. It is a medium-soft to semi-hard cheese made in a large rectangular or brick shape. The cheese is formed by pressing the curds with clay-fired bricks, which also gives it its name. The colour of brick cheese ranges from ivory to pale yellow, with an orange rind. When unaged, it has a sweet, mild, earthy flavour and is suitable for melting, making it a good choice for grilled cheese sandwiches and pizzas.

Detroit-style pizza is said to be chiefly about the cheese blanket and chewy, bronzed crust, so brick cheese is an ideal choice. It is fatty, creamy, and relatively mild, melting very well to spread out and coat the whole pizza. The cheese is also known to be difficult to find outside of the Midwest, and it is not cheap. Those looking to make an authentic Detroit-style pizza may need to call several shops or order the cheese online.

To make Detroit-style pizza, the dough takes a few hours, but most of that is hands-off rising time. The sauce is typically made with crushed or food-milled tomatoes, garlic powder, onion powder, dried oregano, sugar, and spices. However, some prefer to use real garlic instead of powder and add red pepper flakes. The placement of toppings is also a matter of preference, as some put them underneath the cheese, while others place them on top so they get nicely charred.

For those who cannot find or afford brick cheese, there are substitute options available. A blend of mozzarella and white Muenster or Monterey Jack cheese can be used to achieve a similar taste and texture.

Pizza Hut's Cheese: The Secret Behind the Perfect Pizza

You may want to see also

It's a semi-hard cheese with a sweet, mild flavour when young

Brick cheese is a semi-hard cheese with a sweet, mild flavour when young. It is made in the form of a large rectangular or brick shape. The name "brick" comes from the original cheese-making process, where artisans used bricks to press the cheese curds and form its shape. The cheese is surface-ripened with Corynebacterium and Arthrobacter bacteria, which give it a full, earthy flavour. When young, Brick cheese has a sweet and mild flavour, but as it matures, it develops a pungent and tangy taste with a hint of nuttiness.

The process of making Brick cheese is derived from white American Cheddar, but it is cultured at a slightly higher temperature, resulting in a higher fat content and a slightly altered protein structure. This gives Brick cheese a softer texture and a sharper finish compared to regular Cheddar. It was first made in Wisconsin in 1877 by Swiss-born American cheesemaker John Jossi.

Brick cheese is often served melted and is a popular choice for grilled cheese sandwiches, burgers, and pizzas. It pairs well with pickles and can be served with corn polenta or macaroni. When young, Brick cheese is excellent for melting and slicing, making it a versatile ingredient for various dishes.

The cheese has a creamy yellow colour and is covered by a washed rind on the outside. It is considered ready for consumption after two weeks, but it can be aged for up to five months. The ageing process further develops its flavour and aroma, transforming it from a mild and sweet cheese to one with a stronger, nuttier taste and a more pronounced smell.

Best Tool to Mix Cheese Straw Dough?

You may want to see also

Frequently asked questions

Yes, bricks are used in the process of making brick cheese. The cheese curds are pressed with clay-fired bricks, which also give the cheese its brick shape.

Brick cheese is a medium-soft cheese that ranges in color from pale yellow to white with an orange rind. It has a sweet and mild flavor when young, and a strong, nutty flavor when aged.

Brick cheese is made by heating raw milk to 162°F, then cooling it to around 90°F before pumping it into open steel vats. A starter culture of bacteria is added, which starts the fermentation process. Then, a substance called rennet is added, which triggers the curdling of the milk proteins. The curds are cooked for about 40 minutes, cut into cubes, and placed into perforated rectangular molds. The molds are then pressed with bricks to squeeze out the whey.