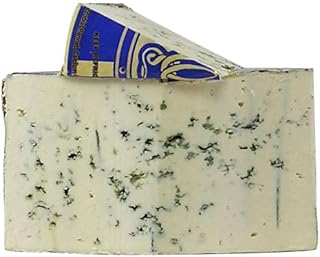

Danish blue cheese, also known as Danablu, is a semi-soft, blue-veined cheese made from cow's milk. It has a creamy texture and a strong aroma, with a salty, sharp flavour. The cheese is light yellow or off-white in colour, with distinctive blue or green veins. Danish blue cheese is made by inserting small copper wires or rods into the cheese curds, which are then left to age for at least 12 weeks in a dark place. As the cheese ages, the blue veins form due to the growth of the bacterium Penicillium roqueforti. Danish blue cheese is often served on bread or biscuits, and has become a popular topping for baked potatoes, steaks and hamburgers.

| Characteristics | Values |

|---|---|

| Type of Milk | Cow's milk |

| Texture | Semi-soft |

| Colour | Off-white, light yellow, or wheatish-yellow |

| Rind | Edible |

| Blue Veins | Created by piercing with steel needles |

| Aging Time | 60-90 days |

| Taste | Salty, sharp, pungent, and mildly bitter |

| Fat Content | 30% |

| Pairings | Suited for sensitive palates; often served with crackers, toast, salads, or fruit |

Explore related products

What You'll Learn

Danish Blue Cheese is made from cow's milk

Danish Blue Cheese, also known as Danablu, is made from cow's milk. It is a semi-soft cheese with an off-white or light yellow appearance, riddled with blue veins. Danish Blue Cheese is typically sold under the brand name of Danish Blue Cheese, especially in North America. The cheese is made using homogenized cream and full-fat cow's milk, resulting in a fat content of approximately 30%.

The process of making Danish Blue Cheese begins with pasteurizing the milk and adding a starter culture to convert lactose to lactic acid, turning the milk from liquid to solid. Rennet is then added to aid coagulation, and the curds are cut and milled. The broken curd is ladled into molds and drained of excess whey. Before aging, the cheese is pierced with steel needles to allow oxygen circulation and encourage the growth of the blue culture, creating the characteristic blue veins.

The aging process for Danish Blue Cheese takes approximately 60 to 90 days. During this time, the cheese develops its distinctive smooth, velvety texture and unique flavor profile. The final product is known for its mild bitterness, saltiness, and sharp, pungent aroma. It is often served on bread, savory biscuits, or crackers and pairs well with seared beef, veal, or pork steak.

Danish Blue Cheese is believed to have evolved from Roquefort Cheese, with a sharper and saltier taste. It is one of the most popular varieties of blue cheese and is known for its creamy and semi-soft texture, making it a good introduction to blue cheese for those who are new to it.

Daiya Cheese: Canadian-Made, Vegan-Friendly Delicacy

You may want to see also

It's a semi-soft cheese with a creamy texture

Danish blue cheese is a semi-soft cheese with a creamy texture. It is made from cow's milk and has an off-white or light yellow appearance with blue veins throughout. The process of making Danish blue cheese involves pasteurizing and homogenizing the milk, adding a starter culture to acidify the milk, and then adding rennet to coagulate it. The curds are then cut and formed into wheels, and the cheese is salted and pierced with steel needles to introduce the mould Penicillium roqueforti and encourage its growth. The cheese is then left to age for about 60 to 90 days, during which time it develops its distinctive flavour and texture.

The creamy and smooth texture of Danish blue cheese sets it apart from crumbly blue cheeses and makes it a popular choice for those new to blue cheese. It has a milder flavour than other blue cheeses like Roquefort and Gorgonzola, with a salty and sharp taste. The fat content of Danish blue cheese is roughly 30%, and it is matured for about three months.

The process of piercing the cheese with needles or wires is unique to the Danablu variety of Danish blue cheese. This step introduces oxygen, which allows the blue mould to grow and creates the distinctive holes in the cheese. The holes contribute to the texture and appearance of the cheese, making it a unique variety.

Danish blue cheese is traditionally served in Denmark on bread or savoury biscuits, but it has gained popularity in other countries as well. It is often paired with seared beef, veal, or pork steak, or used in soups, pastas, or stews to add a creamy consistency. The mild flavour and semi-soft texture of Danish blue cheese make it a good choice for those who are new to blue cheese.

Troubleshooting a Broken Cheese Sauce: What Went Wrong?

You may want to see also

The cheese is pierced with steel needles to allow oxygen to circulate

Danish blue cheese is made from cow's milk and is characterised by its off-white or light yellow appearance with blue veins. Before it is left to age, the cheese is pierced with steel needles, which allow oxygen to circulate and the blue culture to breathe and develop. This process is also known as "needling" and is what creates the signature blue veins of the cheese. The piercing of the cheese with needles also softens the texture and contributes to the flavour of the cheese. Danish blue cheese is typically aged for around two to three months, during which time it matures and develops its distinctive flavour and texture.

The process of piercing the cheese with steel needles is an important step in the production of Danish blue cheese. It involves piercing the cheese with stainless steel rods or wires, which create holes that allow oxygen to circulate through the cheese. This step is essential to encourage the growth of the mould Penicillium roqueforti, which gives Danish blue cheese its characteristic flavour and appearance.

The needling process is typically done by hand, and the cheesemaker will carefully insert the steel needles into the cheese at specific depths and angles to ensure even oxygen circulation. This technique is a traditional method that has been used for centuries to produce blue cheese. It is an art that requires skill and precision to ensure the cheese ages properly and develops the desired flavour and texture.

The size and placement of the needles vary depending on the cheesemaker's preferences and the specific type of blue cheese being produced. Some cheesemakers use longer needles that reach deep into the cheese, while others use shorter needles that create more shallow holes. The number of holes and their distribution throughout the cheese can also vary, depending on the desired level of oxygen circulation and mould growth.

The steel needles used in this process are typically made of stainless steel, which is durable, corrosion-resistant, and easy to sanitise. Some cheesemakers may also use needles made of other materials, such as copper, which has natural antimicrobial properties that can help inhibit the growth of unwanted bacteria. The choice of needle material and design can vary depending on the cheesemaker's traditions, preferences, and the specific type of blue cheese being produced. Danablu, Danbo and Esrom are the only three Danish blue cheeses that are PGI-marked by the EU.

Dairy-Free Delights: Exploring Non-Dairy Cheeses and Their Flavors

You may want to see also

Explore related products

Danish Blue Cheese matures for about three months

Danish Blue Cheese, or Danablu, is a semi-soft cow's milk cheese that matures for about three months. The cheese is formed into drums or blocks and has a white to light yellow appearance with blue veins throughout. The cheese is made by mixing blue culture with milk, along with enzymes and rennet to trigger coagulation. The mixture is then left to sit and curdle, producing a firm curd that is cut and milled. The broken curd is then ladled into molds and drained of excess whey, followed by a brine solution of salt and water. Before the cheese is left to age, it is pierced with steel needles to allow the blue culture to breathe and develop. This process of needling contributes to the flavour and texture of the cheese, creating its distinctive blue veins and softening its texture.

The maturation process of Danish Blue Cheese typically takes about three months, during which the cheese develops its unique flavour and texture. The maturation period allows the blue culture to grow and colonise the cheese, breaking down proteins and fats and producing various compounds that contribute to the cheese's characteristic flavour and aroma. The specific duration of the maturation process can vary depending on the cheesemaker's techniques and desired characteristics of the final product.

During maturation, Danish Blue Cheese is typically aged in controlled environments, such as temperature- and moisture-regulated caves or ageing rooms. These conditions are crucial for the development of the cheese, as they influence the growth of the blue culture and the overall quality of the final product. The temperature and humidity levels are carefully monitored to ensure optimal conditions for the maturation process.

The maturation period also allows for the development of the cheese's texture. As the cheese ages, its moisture content decreases, resulting in a drier and more compact texture. The needling process earlier in the cheese-making process also contributes to the final texture, creating a softer and more velvety mouthfeel. The maturation process further enhances the flavour of Danish Blue Cheese, allowing the salty and sharp notes to become more pronounced and well-rounded.

Overall, the maturation period of about three months is essential for the development of Danish Blue Cheese's distinctive characteristics. It allows for the growth and colonisation of the blue culture, contributing to the cheese's flavour, aroma, and texture. The controlled environment during maturation ensures the optimal development of these characteristics, resulting in a semi-soft cheese with a unique combination of salty and sharp attributes that has gained popularity worldwide.

American Cheese: What's Really in This Dairy Product?

You may want to see also

It's often served on bread or biscuits

Danish blue cheese is often served on bread or biscuits. In Denmark, it is traditional to top biscuits and breads with Danish blue cheese and serve it for breakfast or as a snack. Danish blue cheese is also served in many countries as a snack with crackers or toast, as a crumbly topping for salads, or with fruit as a dessert.

Outside of Denmark, Danish blue cheese has gained popularity as a topping for hamburgers, steaks, and baked potatoes. It is also enjoyed with seared beef, veal, or pork steak, allowing it to melt into the meat. It can also be served in soups, pastas, or stews to add a creamy consistency to the dish.

Danish blue cheese is known for its creamy and semi-soft texture, making it a good option for those who are new to blue cheese and may be hesitant about the crumbly texture of other varieties. It has a milder flavor compared to traditional blue cheese varieties like Gorgonzola, making it more suitable for sensitive palates.

When serving Danish blue cheese on bread or biscuits, it can be paired with complementary flavors such as zesty apple, dark chocolate, or pear to contrast and enhance the flavor of the cheese. These pairings can help introduce skeptical audiences to the world of blue cheese.

The Story of Felta Cheese and Its Maker

You may want to see also

Frequently asked questions

Danish Blue Cheese is made from cow's milk.

Danish Blue Cheese has a milder flavour compared to other blue cheeses. It is known for its creamy and semi-soft texture and sharp, salty taste.

Danish Blue Cheese is made by adding blue culture to the milk, along with enzymes and rennet to trigger coagulation. The mixture is then left to sit and curdle, producing a firm curd that is cut and milled. The broken curd is then ladled into moulds and drained of excess whey. Before it is left to age, the cheese is pierced with steel needles to allow the blue culture to breathe and develop.

Danish Blue Cheese is left to age for about 60 days, producing a smooth and velvety wheel of cheese.