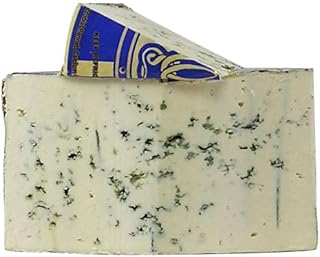

Blue cheese is a type of cheese that is loved by some and hated by others. It is made by mixing bacteria with curds, piercing the cheese to create little tunnels, and allowing air to enter and feed the bacteria, encouraging the mould veins. Copper wire is used in blue cheese production to facilitate oxygen penetration into the cheese curd, creating an environment conducive to the growth of Penicillium roqueforti, the mould responsible for the cheese's distinct flavour and blue veins. The use of copper wire in blue cheese production has been employed for centuries, with no reported adverse health effects.

| Characteristics | Values |

|---|---|

| Copper wire usage | To facilitate oxygen penetration into the cheese curd |

| Copper wire usage | To create an environment for the growth of Penicillium roqueforti, the mold responsible for the distinct flavor and blue veins |

| Copper wire usage | It is safe for consumption as the amount of copper present in the cheese is minimal and poses no health risks |

| Copper wire usage | It is a naturally occurring element found in various foods like nuts, seeds, and seafood |

| Blue cheese making | Bacteria is mixed through the curds before shaping |

| Blue cheese making | The cheese is perforated with long needles to provide entry to the air that feeds the molds, helping them proliferate and form blue veins |

Explore related products

What You'll Learn

- Copper wire is used to facilitate oxygen penetration into the cheese curd

- Copper wire is safe to use and does not pose any health risks

- The mould feeds on the oxygen, producing enzymes that break down fats and proteins

- Copper wire is used to create an environment for the growth of Penicillium roqueforti

- Copper wire is used in blue cheese production due to its exceptional conductivity and malleability

Copper wire is used to facilitate oxygen penetration into the cheese curd

The use of copper wire in blue cheese production is a fascinating example of the intricate relationship between food and science. Copper wire, known for its exceptional conductivity and malleability in electrical wiring and telecommunications, has also proven useful in the culinary arts. In the context of blue cheese, copper wire plays a crucial role in facilitating oxygen penetration into the cheese curd.

During the cheesemaking process, the introduction of air is essential for the growth of mould. Blue cheese, in particular, relies on the development of specific moulds, such as Penicillium roqueforti, to create its distinct flavour and blue veins. This mould occurs naturally and was reportedly discovered in France as early as 74 AD.

To encourage the growth of this mould, cheesemakers perforate the maturing cheese with long needles or rods, creating tunnels that allow air to enter and feed the bacteria. While stainless steel or brass needles are commonly used today, copper wire has been traditionally employed for this purpose. The copper wire is inserted into the cheese curd, allowing oxygen to penetrate and create an environment conducive to mould growth.

The use of copper wire in blue cheese production is a testament to the creativity and ingenuity of cheesemakers throughout history. It is said that the makers of Danish Blue experimented with copper rods, and the resulting flavour was deemed satisfactory, leading to the adoption of this practice. The minute amount of copper present in the cheese poses no health risks and contributes to its unique flavour profile.

Comte Cheese: A French Alpine Delight

You may want to see also

Copper wire is safe to use and does not pose any health risks

The minute amount of copper present in blue cheese is naturally occurring and contributes to the cheese's unique flavour profile. The use of copper wire in this context showcases the intricate relationship between food and science, specifically how different elements can shape flavour and texture. In the case of blue cheese, copper wire is used to facilitate oxygen penetration into the cheese curd, creating an environment that promotes the growth of Penicillium roqueforti, the mould responsible for the cheese's distinct flavour and blue veins.

It is important to note that while copper wire is safe for food production, it is not the only method used to create blue cheese. Steel rods, for example, are now commonly used to introduce air and create the mould during the cheesemaking process. Some artisanal cheesemakers even use knitting needles to poke holes in the cheese, though this practice is less common today.

The texture of blue cheese can vary from very soft and creamy to crumbly and dry, depending on the age of the cheese. Young cheeses tend to be softer, while older cheeses become drier. Despite these variations in texture, the basic process of making blue cheese remains the same, starting with milk, salt, and a coagulant, and ending with the distinctive blue veins and complex flavour that we know and love (or hate!).

So, while the use of copper wire in blue cheese production may seem unconventional, it is safe to consume and plays an important role in creating the unique characteristics of this beloved (or despised) delicacy.

Cashel Blue Cheese: A Tasty Irish Delicacy

You may want to see also

The mould feeds on the oxygen, producing enzymes that break down fats and proteins

The use of copper wire in blue cheese production is a fascinating example of how specific elements can shape flavour and texture. It is a testament to the creativity and ingenuity of cheesemakers. The copper wire facilitates oxygen penetration into the cheese curd, creating an environment that supports the growth of Penicillium roqueforti, the mould responsible for the distinct flavour and blue veins of blue cheese.

When the mould feeds on the oxygen, it produces enzymes that break down fats and proteins in the cheese. This process results in the formation of the characteristic blue veins and contributes to the complex flavour profile of blue cheese. The mould, Penicillium roqueforti, is a naturally occurring bacteria discovered in France as early as 74 AD.

The process of making blue cheese involves introducing air during the cheesemaking process. After the cheese curds are shaped, they are "needled" or pierced with long needles to create tunnels for air to enter and feed the bacteria, encouraging the mould veins. While stainless steel or brass needles are commonly used today, some artisanal cheesemakers still use knitting needles or steel rods to poke holes in the cheese.

The use of copper wire in blue cheese production is not a recent innovation. It has been employed for centuries, and the minute amount of copper present in the cheese is safe for consumption, contributing to its unique flavour. The copper wire is left in the cheese for an extended period, and its presence enhances oxygen penetration, benefiting the growth of the mould.

The intricate relationship between copper, oxygen, and mould in blue cheese production showcases the innovative techniques cheesemakers have developed over the years. The combination of these elements results in the distinctive flavour, texture, and appearance of blue cheese, making it a beloved or hated delicacy worldwide.

History of Red Leicester Cheese: When Was It Created?

You may want to see also

Explore related products

Copper wire is used to create an environment for the growth of Penicillium roqueforti

Blue cheese is made by mixing bacteria with curds, shaping the mixture, and then piercing it to create tunnels that allow air to enter and feed the bacteria, encouraging mould veins. Copper wire is used to create an environment for the growth of Penicillium roqueforti, the mould responsible for the distinct flavour and blue veins of blue cheese. Copper wire facilitates oxygen penetration into the cheese curd, creating optimal conditions for the growth of Penicillium roqueforti.

The use of copper wire in blue cheese production is a long-standing tradition, with no adverse health effects reported. Copper is naturally present in various foods, including nuts, seeds, and seafood, and the amount of copper in blue cheese is minimal, posing no health risks. The incorporation of copper wire showcases the creativity and ingenuity of cheesemakers, highlighting the intricate relationship between food and science.

Historically, cheesemakers used knitting needles, wooden or bone needles, or experimented with stainless steel to create the holes in the cheese. However, the Danish Blue cheesemakers' accidental use of copper rods, which were left in a little too long, resulted in a flavour that was deemed satisfactory, and thus the use of copper wire in blue cheese production was adopted.

Today, cheesemakers typically use steel or stainless-steel rods to create the holes in the cheese, but the use of copper wire remains an integral part of the traditional blue cheese-making process. The technique has been passed down through generations, contributing to the unique flavour profile of blue cheese.

Chao Cheese: A Delicious Blend of Coconut and Milk

You may want to see also

Copper wire is used in blue cheese production due to its exceptional conductivity and malleability

Copper wire has been used in blue cheese production for centuries, with no adverse health effects reported. It is a naturally occurring element found in various foods, including nuts, seeds, and seafood. The minute amount of copper present in blue cheese is safe for consumption and contributes to the cheese's unique flavour profile.

The use of copper wire in blue cheese production showcases the intricate relationship between food and science, highlighting how specific elements can shape flavour and texture. Copper wire is used to facilitate oxygen penetration into the cheese curd, creating an environment conducive to the growth of Penicillium roqueforti, the mould responsible for the cheese's distinct flavour and blue veins.

Blue cheese is made by mixing bacteria with the curds just before they are shaped. After shaping, the cheese is 'needled' or perforated with long needles to create tunnels for air to enter and feed the bacteria, encouraging the mould veins. Copper wire, with its exceptional conductivity and malleability, is ideal for this needling process as it can easily conduct oxygen into the cheese curd and create the desired environment for mould growth.

While some cheesemakers experimented with stainless steel, the makers of Danish Blue opted for copper rods. On one occasion, these copper rods were left in a little too long, but the resulting cheese was deemed satisfactory, and thus the use of copper in blue cheese production was adopted.

Cheese Whiz: What's in the Jar?

You may want to see also

Frequently asked questions

Yes, it is safe to consume blue cheese made with copper wire. The amount of copper present in the cheese is minimal and poses no health risks. Copper is a naturally occurring element found in various foods, including nuts, seeds, and seafood.

Copper wire is used to facilitate oxygen penetration into the cheese curd, creating an environment conducive to the growth of Penicillium roqueforti, the mold responsible for the cheese’s distinct flavor and blue veins.

Copper wire is widely used in electrical wiring, telecommunications, and various industrial processes due to its exceptional conductivity and malleability.

Blue cheese is made in a similar way to white mold cheese, like Camembert or Brie. Instead of being sprayed with mold to encourage surface bacteria, bacteria are mixed through the curds just before they are shaped. After shaping, the cheese is 'needled' with steel or brass rods, or in the past, copper rods, to create little tunnels to allow air to enter and feed the bacteria, encouraging the mold veins.