Parmesan cheese is traditionally made from cow's milk and is aged for at least 12 months. The process of making Parmesan cheese involves combining whole milk and naturally skimmed milk, which is then heated in copper vats. During this two-step heating process, additional ingredients like whey and rennet are added to form the curd. The amount of aging time is the biggest difference between Parmesan and other kinds of cheese.

Explore related products

What You'll Learn

Parmesan is made from cow's milk

Parmesan is a hard, granular cheese that is traditionally made from cow's milk. It is produced by combining whole milk and naturally skimmed milk, which is then heated in copper vats. During this two-step heating process, additional ingredients like whey and rennet are added to form the curd. The curd is then moved to a mould.

The use of cow's milk is a key factor in defining Parmesan, with the cheese being legally required to be made from cow's milk in the United States. In Europe, the term Parmesan is protected by law and can only be used to refer to Parmigiano Reggiano, which is made in a restricted geographic area in northern Italy using stringently defined methods. The name Parmigiano Reggiano refers to the Italian provinces of Parma and Reggio Emilia, where the cheese is produced.

The process of making Parmesan involves a long aging time, with the cheese being aged for at least 12 months to develop its distinct flavour. Some varieties of Parmesan are aged for even longer periods, up to 16 months, to create a sweeter taste through the natural fermentation of the cow's milk. This aging process also contributes to the low lactose content of Parmesan, making it suitable for those with lactose intolerance.

The unique flavour and texture of Parmesan have made it a popular cheese worldwide, with many similar cheeses produced in other regions. Grana Padano, for example, is produced in Lombardy, Italy, and has a similar nutty flavour to Parmesan but is slightly softer in texture. Other similar cheeses include Pecorino Romano, which is made from sheep's milk, and Pieve, which is considered the closest in taste to Parmesan.

The Art of Making Paneer Cheese

You may want to see also

Rennet is added to form curds

Parmesan cheese is traditionally made from cow's milk. Whole milk and naturally skimmed milk are combined and then distributed into copper vats for heating. During the two-step heating process, additional ingredients like whey and rennet are added to form the curd. Rennet is a natural enzyme found in the stomach of young mammals, which helps them digest their mother's milk. It is added to the milk to make Parmesan cheese.

The amount of rennet added to the milk depends on the quality of the milk. If you are using pasteurized milk, you can follow the standard recipe. However, if you are using better-quality, raw milk, you should decrease the amount of rennet added by 25-30%. The coagulation time should also be reduced by 40-50%.

The milk and rennet mixture should be heated slowly to 91-93°F (32.7-33.8°C). This can be done using a milk pot in a water bath or directly on a stovetop, but it is important to be careful with the heating.

Once the rennet has been added and the milk has been heated to the correct temperature, the mixture will begin to form curds. This is a crucial step in the cheese-making process, as the curds are what will eventually become the solid cheese. The curds must be carefully separated from the whey (the liquid left over after the milk has curdled) and transferred to a sanitized mould to continue the cheese-forming process.

The Making of Cheese Triangles: A Step-by-Step Guide

You may want to see also

It's aged for at least 12 months

Parmesan cheese is aged for a minimum of 12 months to develop its distinctive flavour and texture. This lengthy aging process is a key part of the traditional method of making Parmesan, and it is one of the reasons the cheese is so highly regarded. The aging time can even be longer, with some producers ageing their Parmesan for 16 months to create a sweeter flavour.

The aging process for Parmesan is carefully controlled, and the cheese is typically aged in temperature- and humidity-controlled environments. This ensures the cheese matures consistently and develops the desired flavour and texture characteristics. During aging, natural fermentation occurs, transforming the cheese's texture and flavour.

The length of aging also depends on the type of Parmesan being produced. For example, the minimum aging time for Grana Padano, a similar cheese to Parmesan, is nine months. Piave, another alternative, has a shorter aging period due to its softer texture.

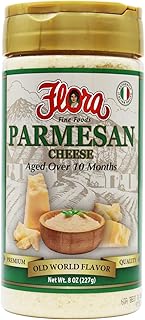

In the United States, regulations specify that Parmesan must be cured for at least 10 months. However, American-style Parmesan is often aged for less than 12 months, contributing to a slightly different flavour profile and texture compared to traditional Italian Parmesan.

The aging time is crucial in developing the complex flavours of Parmesan. The longer aging period allows the cheese to lose moisture and become more concentrated in flavour. This results in a harder texture that is ideal for grating, as well as a more intense, nutty taste that has made Parmesan a beloved ingredient in dishes worldwide.

Cheese Packaging: Material Matters for Freshness

You may want to see also

Explore related products

It's defined differently outside of Europe

Parmesan cheese is defined differently in various jurisdictions outside of Europe. In 1955, Parmigiano Reggiano became a certified name, and in 2008, an EU court ruled that the name Parmesan in Europe exclusively refers to Parmigiano Reggiano. As a result, the term Parmesan may only be used within the European Union to refer to Parmigiano Reggiano, which must be made in a restricted geographic area using specific methods.

In the United States, the Code of Federal Regulations includes a Standard of Identity for "Parmesan and Reggiano cheese," outlining production and final result requirements. Parmesan must be made from cow's milk, cured for at least 10 months, contain no more than 32% water, and have a minimum of 32% milk fat in its solids. Similarly, Canadian regulations define moisture and fat levels without restricting aging time. Several North American producers, including Kraft Foods, have been selling grated Parmesan since 1945, and many Wisconsin cheesemakers founded by Italian immigrants produce Parmesan in whole wheels.

Outside of Europe and Lisbon Agreement countries, Parmesan is a locally produced imitation of Parmigiano Reggiano. The name Parmesan has become genericized in many areas outside of Europe, denoting various hard Italian-style grating cheeses. These cheeses, primarily from the US and Argentina, are commercialized under names resembling the original, such as Parmesan, Parmigiana, Parmesana, and Real Parma. After the European ruling prohibiting the use of "Parmesan" as a generic name, Kraft Foods renamed its grated cheese "Pamesello" in Europe.

Several American manufacturers have been investigated for allegedly exceeding the 4% cellulose limit allowed in grated cheese. In one case, a Pennsylvania manufacturer was found guilty of producing a product labeled as "Parmesan" that did not contain any Parmesan cheese. The manufacturer was sentenced to three years of probation, a $5,000 fine, and 200 hours of community service. While Parmesan is traditionally made with rennet, a non-vegetarian ingredient, some producers like Cello Cheese use microbial rennet to create vegetarian and halal-friendly options.

The Art of Natural Cheese Making

You may want to see also

It's low in lactose

Parmesan cheese is known for its rich, sharp flavour, nutty tones, and hints of browned butter. It is traditionally made with cow's milk and aged for at least 12 months, with some varieties being matured for up to 70 months. This long aging process is what makes Parmesan cheese a low-lactose food.

The maturation process is crucial in making parmesan into the cheese we know and love. As the cheese matures, bacterial cultures flourish and feed on the milk sugar, transforming it into lactic acid. This conversion is what gives the cheese its distinctive flavour. So, the rule of thumb is that the longer the cheese matures, the lower its lactose content. This is why hard, aged cheeses frequently contain less lactose than fresh and unripened cheeses.

The lactose level in Parmesan cheese is typically below one per cent, making it safe for most lactose-intolerant individuals. However, some people have reported experiencing adverse reactions to Parmesan despite its low lactose content. This could be due to a histamine allergy or sensitivity to the aging process, as aged cheeses have a high amount of histamines. Additionally, Parmesan is made from skimmed milk and whey, which is added back into the mixture. Whey is one of the proteins in dairy that can cause symptoms similar to lactose intolerance.

It is important to note that the lactose content in Parmesan cheese can vary depending on the ageing process and the specific product used. The lactose content can range from 0-3 grams of lactose per 100 grams of cheese. Therefore, those with lactose intolerance should be mindful of their consumption and choose products with lower lactose levels to suit their dietary needs.

The Making of Cheddar Cheese: A Commercial Guide

You may want to see also

Frequently asked questions

Parmesan cheese is traditionally made from cow's milk.

Parmesan is typically aged for at least 12 months, though some varieties are aged for longer.

Whole milk and naturally skimmed milk are combined and heated in copper vats. During this two-step heating process, additional ingredients like whey and rennet are added to form the curd.

Parmigiano Reggiano is a protected designation of origin (PDO) for cheeses produced in specific provinces of Italy under Italian and European law. Outside of the European Union, the term Parmesan may refer to a locally produced imitation of Parmigiano Reggiano.