Parmigiano Reggiano, or as it is more commonly known, Parmesan, is a hard, granular cheese produced from cow's milk. It is one of the most ancient and unique cheeses and is considered the 'king of cheeses'. Parmigiano Reggiano is made in a restricted geographical area in Italy, using stringently defined methods. The milk used can only come from cows that are fed locally grown forage, grass, and hay. The cheese is then aged for a minimum of 12 months, but it can mature for much longer, with its texture becoming crumbly and pleasantly grainy, and its aroma and flavour deepening with notes of spice and nuts.

| Characteristics | Values |

|---|---|

| Place of origin | Parma and Reggio Emilia, Italy |

| Production area | Parma, Reggio Emilia, Modena, Bologna (west of the River Reno), and Mantua (south of the River Po) |

| Milk source | Raw milk from cows fed locally grown forage, grass, and hay |

| Minimum aging period | 12 months |

| Ideal pairing | 12 or 18 months-old Parmigiano Reggiano pairs well with sparkling and white wine; 24 months or older pairs well with red wine |

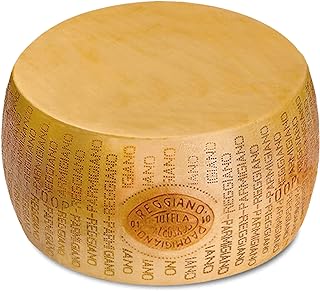

| Identification | The wheel is engraved with markings on its rind, including the date of production, dairy ID, PDO seal, and more |

Explore related products

What You'll Learn

Milk from cows fed local forage, grass, and hay

The milk used for Parmigiano Reggiano can only come from cows that are fed locally grown forage, grass, and hay. This is a key reason why Parmigiano Reggiano is so special. The cows' diet is a crucial factor in determining the health of the milk and the cow. The diet also significantly influences the cheese's colour, texture, taste, and smell.

Research has been conducted on the link between feeding dairy cows and Parmigiano-Reggiano cheese production. One study found that the addition of wild garlic leaves resulted in a less milky and sour taste and smell, while modifying the colour and some textural properties. Another study focused on eliminating soybeans from the cows' diet. The control diet contained 8kg of medium-quality alfalfa hay, 2kg of Italian ryegrass hay, and 4kg of concentrate containing 21% soybean meal. The GMO-free diet contained 13kg of high-quality alfalfa hay and 1.2kg of concentrate without soybean meal. The results showed that animal performance and dry matter intake were not affected by the diet.

In addition to diet, the breed of cow also plays a role in the production of Parmigiano Reggiano. Before the second-wave Industrial Revolution in the early 1900s, the three main cow breeds used to make the cheese were the Bruna Alpina brown cow, the Reggiana red cow, and the Bianca Modenese white cow. However, with the rise in popularity of this versatile cheese, cheesemakers began using the Friesian cow, which could produce a much higher yield of milk than the traditional breeds. Today, the most common breed among Parmigiano cheese makers is the Holstein Friesian cow, known for its high milk productivity.

The process of making Parmigiano Reggiano involves ageing the cheese for a minimum of 12 months, but it can mature for much longer. The cheese is then tested by a master grader who taps each wheel to identify any cracks or voids. Wheels that pass the test are heat-branded on the rind with the Consorzio's logo. Parmigiano Reggiano is best enjoyed grated, shaved, or tossed into dishes such as pasta, soup, omelettes, pizza, or salads.

McDonald's Cheeseburger: Decoding the Ingredients

You may want to see also

Minimum 12 months ageing

Parmigiano Reggiano is aged for a minimum of 12 months, but it can mature for much longer. The cheese is placed on wooden shelves in special ageing rooms within the plant. Each cheese and the shelf underneath it is cleaned every seven days, and the cheese is turned.

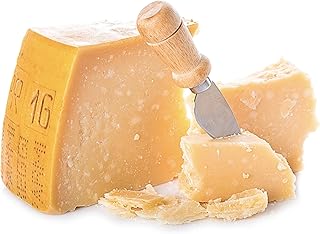

The longer the maturation, the more the aroma, texture, and flavour evolve. At 12 or 18 months, the cheese is more delicate, fresh, and milk-forward. Over time, its texture becomes crumbly and pleasantly grainy, while its aroma and flavour deepen with notes of spice and nuts. Parmigiano Reggiano aged for 12 or 18 months pairs well with sparkling and white wine, while the cheese aged for 24 months or longer pairs well with red wine.

The ageing process also results in the formation of 'little crystals' in the cheese. These are not salt crystals, as many believe, but the amino acid tyroside, a constituent part of the milk protein casein.

The minimum ageing period of 12 months is one of the reasons why Parmigiano Reggiano is so special. It is also one of the factors that contribute to its status as a protected designation of origin (PDO) product.

The Cheddar Cheese Masters: Where is it Made?

You may want to see also

Produced in Parma, Reggio Emilia, Modena, Bologna, and Mantua

Parmigiano Reggiano, or Parmesan, is a hard, granular cheese produced from cow's milk. It is named after two of the areas that produce it: the Italian provinces of Parma and Reggio Emilia. It is also produced in the part of Bologna west of the River Reno, in Modena, and in the part of Mantua (Lombardy) on the south bank of the River Po.

Parmigiano Reggiano is a protected designation of origin (PDO) product, which means it can only be produced in these provinces under Italian and European law. The milk used for Parmigiano Reggiano must come from cows fed locally grown forage, grass, and hay. The cows' diet, including a strict ban on the use of silage, guarantees the specific characteristics of the cheese.

The process of making Parmigiano Reggiano has been used for almost 1,000 years. First, the curd is cut into small particles the size of rice grains to ensure a fine, granular texture. The cheese is then put into a stainless steel, round form that is pulled tight with a spring-powered buckle so it retains its wheel shape. After a day or two, the buckle is released, and a plastic belt imprinted with the Parmigiano Reggiano name, the plant's number, and the month and year of production is put around the cheese. The wheel is then put into a brine bath to absorb salt for 19-25 days. After brining, the wheels are transferred to aging rooms in the plant for a minimum of 12 months. Each cheese is placed on wooden shelves, and each cheese and the shelf underneath it is cleaned and turned every seven days.

The aroma, texture, and flavour of Parmigiano Reggiano evolve as it ages. At 12 or 18 months, the cheese is more delicate, fresh, and milk-forward, but over time, its texture becomes crumbly and pleasantly grainy, while its aroma and flavour deepen with notes of spice and nuts. Parmigiano Reggiano aged for 12 or 18 months pairs well with sparkling and white wine, while cheese aged for 24 months or longer pairs well with red wine.

The Authentic Parmesan Cheese Regions in Italy

You may want to see also

Explore related products

Made with raw milk, rennet, and salt

Parmigiano Reggiano, or Parmesan, is a hard, granular Italian cheese. It is made with raw milk, rennet, and salt. The milk comes from cows fed on locally grown forage, grass, and hay from a restricted geographical area. This area includes parts of the provinces of Bologna, Mantua, Modena, Parma, and Reggio Emilia. The cows' diet is strictly banned from including silage, and their milk has distinct physical, chemical, and microbiological properties that guarantee the characteristics of Parmigiano Reggiano.

To make the cheese, the milk is heated slowly to 91-93°F (32.7-33.8°C). The curd is then cut into small particles the size of rice grains to ensure a fine, granular texture. The cheese is then put into a straight mould for a day, followed by a night in a plastic 'matrix' to imprint information about its production, including the month and year, on the rind. On the third day, the cheese is transferred to stainless steel moulds for two days, after which it is shaped and ready to be salted.

The cheese is then submerged in a heavily salted brine made with Sicilian salt for 19-25 days. After brining, the cheese is transferred to aging rooms in the plant for at least 12 months, during which time it is cleaned and turned every seven days. The longer the cheese is aged, the more its texture, aroma, and flavour evolve. Parmigiano Reggiano aged for 12 or 18 months pairs well with sparkling and white wine, while 24 months or longer pairs well with red wine.

The Making of Bandon Cheese: A Tasty Location

You may want to see also

Recognised by intricate inscriptions on the rind

Parmigiano Reggiano, or Parmesan, is a hard, granular cheese produced from cow's milk and aged for at least 12 months. It is named after two of the areas that produce it: the Italian provinces of Parma and Reggio Emilia. The name Parmigiano Reggiano is a protected designation of origin (PDO) for cheeses produced in these provinces under Italian and European law.

The process of making Parmigiano Reggiano has been refined over almost 1,000 years, and the cheese is now highly regulated to protect against food fraud. The milk used must come from cows fed locally grown forage, grass, and hay, and produced in a restricted geographical area. The specific diet of the cows gives the milk its unique physical, chemical, and microbiological properties, which guarantee the specific characteristics of Parmigiano Reggiano.

After the milk is prepared, it is poured into a stainless steel, round form that is pulled tight with a spring-powered buckle so the cheese retains its wheel shape. The cheese remains in this mould for one day, after which it is transferred to a plastic 'matrix' to imprint information about its production on the rind. This includes the intricate Parmigiano Reggiano inscriptions, the production month and year, and the dairy ID. The following day, the cheese is transferred into stainless steel moulds for two days.

The inscriptions on the rind are an important part of the Parmigiano Reggiano PDO specifications, which help to distinguish the cheese from imitations. The intricate inscriptions on the rind, along with the other markings, ensure that consumers can trust they are buying true Parmigiano Reggiano.

Crystal Farms Cheese: Where Is It Really From?

You may want to see also

Frequently asked questions

Parmigiano Reggiano is made from raw milk, rennet, and salt. The milk comes from cows in a defined geographical area, which are fed a diet of locally grown forage, grass, and hay. The curd is cut into small particles the size of rice grains to ensure a fine, granular texture. The cheese is then put into a stainless steel mould for a few days before being transferred to a brine bath to absorb salt for 19-25 days. After brining, the cheese is transferred to aging rooms in the plant for a minimum of 12 months.

Parmigiano Reggiano cheese is aged for a minimum of 12 months, but it can also be matured for much longer – 24 months, 36 months, 40 months, or even longer. The longer the cheese is aged, the more its texture, aroma, and flavor evolve.

Parmigiano Reggiano is best enjoyed grated over pasta. It can also be shaved over soup, tucked inside an omelette, used as a pizza garnish, or tossed into salads.

Within the European Union, the term Parmesan may only be used, by law, to refer to Parmigiano Reggiano itself. Parmigiano Reggiano is a protected designation of origin (PDO) product, and outside the EU, Parmesan may refer to imitation Parmesan or a family of hard-grating cheeses made from cow's milk and inspired by the original Italian cheese.