Parmigiano Reggiano, commonly known as Parmesan, is a hard, granular cheese produced from cow's milk and aged for at least 12 months. It is named after the Italian provinces of Parma and Reggio Emilia, where it is primarily produced, along with other regions in northern Italy. Parmigiano Reggiano is made with partially skimmed raw milk from cows that feed on grass or preserved fodder, and it undergoes a meticulous production process that includes brine baths and aging. Its complex flavour and granular texture have earned it the title of King of Cheeses. Outside of the European Union, the term Parmesan is used for similar cheeses produced in various countries, but none can replicate the authentic Parmigiano Reggiano of Italy.

| Characteristics | Values |

|---|---|

| Name | Parmigiano Reggiano |

| Common Name | Parmesan |

| Origin | Parma, Reggio Emilia, Bologna, Mantua, Modena (Italy) |

| Production Area | Emilia-Romagna, Lombardy (Italy) |

| Milk Type | Cow's Milk |

| Milk Specification | Raw, Partially Skimmed, Grass-Fed |

| Milk Collection | Morning milk combined with previous evening's skimmed milk |

| Milk Processing Time | Within a day of collection |

| Production Method | Made in copper cauldrons, formed into 75-85 pound cylinders |

| Aging | Minimum 12 months, up to 40 months or more |

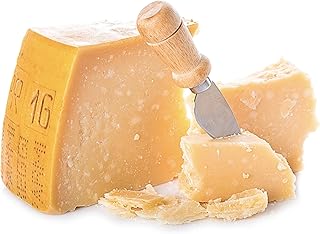

| Texture | Hard, Dry, Dense, Granular |

| Rind | Hard, Pale Golden |

| Interior | Straw-Colored |

| Flavor | Rich, Sharp, Nutty, Savory, Caramel Sweetness |

| Use | Grated over pasta, soups, salads, or as a snack |

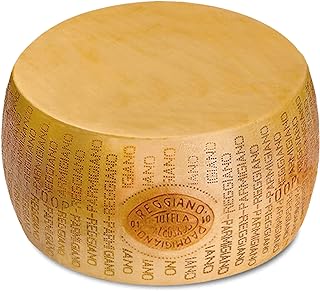

| Authenticity | Sealed with dairy identification, production details, and aging stamps |

Explore related products

What You'll Learn

Reggiano is made from cow's milk

Reggiano, or Parmigiano Reggiano, is a hard, granular cheese made from cow's milk. It is produced in the Italian provinces of Parma and Reggio Emilia, as well as in parts of Bologna, Modena, and Mantua. The name "Reggiano" comes from the Italian adjective for the province of Reggio Emilia.

The process of making Reggiano begins with combining whole milk from the morning milking with skimmed milk from the previous evening. This mixture is then formed into 75-85 pound cylinders, or wheels, and processed within a day of collecting the milk. The cheese wheels are then soaked in a brine bath for 20 to 25 hours before being transferred to an aging facility, where they are aged for at least 12 months. After this initial aging period, each wheel is inspected by a master grader, and if it meets the quality standards, it is branded with the consortium's insignia.

The regulations for producing Reggiano are strict, and it is a protected designation of origin (PDO) product. This means that the name "Parmigiano Reggiano" can only be used for cheese produced in these specific provinces under Italian and European law. The production methods are also stringently defined, including the requirement to use raw cow's milk.

The cows that produce the milk for Reggiano typically feed on grass, and the milk may contain slightly less fat. The milk used for Reggiano must be processed within one day of collection, and the cheese is then aged for a minimum of 12 months, although some versions may be aged for up to four years or more. This lengthy aging process contributes to the development of Reggiano's characteristic granular texture and rich, sharp flavor.

The Mystery Behind Cheese Flavoring: Ingredients and Science

You may want to see also

It's produced in Parma and Reggio Emilia

Parmigiano Reggiano is named after two of the areas which produce it: the Italian provinces of Parma and Reggio Emilia. Parmigiano is the Italian adjective for the city and province of Parma, and Reggiano is the adjective for the province of Reggio Emilia. The cheese is also produced in the part of Bologna west of the River Reno and in Modena, all located in the Emilia-Romagna region. It is also made in the part of Mantua (Lombardy) on the south bank of the River Po.

Parmigiano Reggiano is a PDO (protected designation of origin) cheese, which means its production is highly regulated. It must be made using raw cow's milk from these provinces in the Emilia-Romagna region of Italy. Whole milk collected from the morning milking is combined with the previous evening's skimmed milk to create 75-85 pound cylinders. The milk must be processed within a day after collection. The cheese wheels sit in a brine bath for 20 to 25 hours before being transferred to an aging facility for at least 12 months. After this time, each wheel is hand-inspected by a master grader from Il Consorzio del Formaggio Parmigiano Reggiano. If it passes the test, its rind is branded with the consortium's insignia.

Parmigiano Reggiano has been a staple of Italian cuisine since the 1300s. Its complex, granular bite feels like pyrotechnic particles of sweet onion grass, cashew, pineapple and lactic acid on the tongue. Its high level of the amino acid glutamate gives it fragrant notes of umami and the Mediterranean Sea.

Cannolis: Ricotta Cheese, the Traditional Filling?

You may want to see also

It's a protected designation of origin (PDO)

Parmigiano Reggiano is a protected designation of origin (PDO) product, which means its production is highly regulated. It is produced in a limited area in northern Italy, specifically in the provinces of Parma, Reggio Emilia, Modena, Bologna, and Mantua in the Emilia-Romagna region of Italy. The name Parmigiano Reggiano is derived from these two areas, with "Parmigiano" being the Italian adjective for the city and province of Parma, and "Reggiano" being the adjective for the province of Reggio Emilia.

Under Italian and European law, the names Parmigiano Reggiano and Parmesan are protected designations of origin (PDO) for cheeses produced in these provinces. This means that, within the European Union, the term Parmesan may only be used, by law, to refer to Parmigiano Reggiano itself, which must be made in this restricted geographic area, using stringently defined methods. The name protection laws are so strict that an EU Court ruled in 2008 that even the term "Parmesan" can only be used if the cheese is PDO Parmigiano Reggiano.

Special seals identify Parmigiano Reggiano as authentic, with the identification number of the dairy, the production month and year, a code identifying the individual wheel, and stamps regarding the length of aging. The cheese wheels are formed into 75-85 pound cylinders and sit in a brine bath for 20 to 25 hours before they are transferred to an aging facility. After 12 months, each wheel is hand-inspected by a master grader from Il Consorzio del Formaggio Parmigiano Reggiano, and if it passes the quality test, its rind is branded with the consortium's insignia.

Parmigiano Reggiano has been a staple of Italian cuisine since the 1300s and is often called the "King of Cheeses". Its complex, granular bite feels like pyrotechnic particles of sweet onion grass, cashew, pineapple, and lactic acid on the tongue. Its dense paste is pierced with spires of crystallized amino acids, which interlude the harmony of sweet and savory notes.

Goat Cheese Making: A Step-by-Step Guide

You may want to see also

Explore related products

Reggiano is a hard, dry, granular cheese

Parmigiano Reggiano is a hard, dry, granular cheese. It is made in the Po River Valley with raw, grass-fed, cow's milk from the provinces of Parma, Reggio Emilia, Modena, Bologna, and Mantova in the Emilia-Romagna region of Italy. The milk is partially skimmed, and the morning's whole milk is combined with skimmed milk from the previous evening to create 75-85 pound cylinders. The milk must be processed within a day of collection.

The cheese wheels are then placed in a brine bath for 20 to 25 hours before being transferred to an aging facility for at least 12 months. After this time, each wheel is hand-inspected by a master grader, and if it passes, it is branded with the consortium's insignia. The longer the cheese is aged, the harder and more granular it becomes. Parmigiano Reggiano aged for 12-18 months has a delicate texture and aromas of yogurt and fresh fruit. Parmigiano Reggiano aged for 22-24 months has a grainy texture and balanced flavors of broth and dried fruit. When aged for 30-36 months, the cheese becomes crumbly and grainy, with notes of spice, toasted nuts, and beef broth. Parmigiano Reggiano aged for more than 40 months has a very hard and complex texture.

The complex, granular texture and rich, sharp flavor of Parmigiano Reggiano are a result of the long aging process. The cheese is characterized by crystallized proteins that give it a dynamic aromatic quality and a texturally complex character. Parmigiano Reggiano is a staple of Italian cuisine and is often grated over pasta, soups, and salads, or enjoyed as a snack, especially when paired with Prosciutto di Parma.

Cheese Origins: Exploring Milk Varieties and Their Flavors

You may want to see also

It's aged for at least 12 months

Reggiano, or Parmigiano Reggiano, is aged for a minimum of 12 months. This is a key part of the process, as it is what gives the cheese its distinctive character. After being formed into 75-85 pound cylinders, the wheels of cheese are left to age for at least a year. Each wheel is then hand-inspected by a master grader from Il Consorzio del Formaggio Parmigiano Reggiano. If the cheese passes the test, its rind is branded with the consortium's insignia.

The length of the ageing process is what gives the cheese its complex flavour and texture. The longer the cheese is aged, the more granular and crumbly it becomes, with a harder texture. The flavour also becomes more complex and rich, with notes of spice, toasted nuts, beef broth, and dried fruit. The minimum ageing time of 12 months results in Reggiano cheese having a delicate, crumbly texture and aromas of yoghurt and fresh fruit.

The ageing process also affects the colour of the cheese. As it ages, Reggiano develops a hard, pale-golden rind and a straw-coloured interior. The longer the cheese is aged, the darker the rind becomes.

The minimum ageing time of 12 months is also important for safety reasons. Cheeses that are aged for less time are more likely to contain harmful bacteria that can make people sick. By ageing the cheese for at least a year, producers can ensure that any harmful bacteria have been eliminated.

Finally, the ageing time affects the price of the cheese. Reggiano that has been aged for longer is generally more expensive than cheese that has been aged for a shorter time. This is because the longer ageing time results in a more complex and desirable flavour and texture. It is also due to the fact that longer ageing times require more expertise and care to ensure that the cheese ages properly.

The Ultimate Cheese Enchilada Recipe Ingredients Explained

You may want to see also

Frequently asked questions

Reggian cheese, or Parmigiano Reggiano, is a hard, granular cheese made from cow's milk and aged for at least 12 months. It is produced in the Italian provinces of Parma and Reggio Emilia, as well as in parts of Bologna, Modena, and Lombardy.

Reggian cheese is traditionally made using raw, grass-fed cow's milk from the provinces of Parma, Reggio Emilia, Modena, Bologna, and Mantova in the Emilia-Romagna region of Italy. The whole milk collected from the morning milking is combined with the previous evening's skimmed milk to create 75-85 pound cylinders. The milk must be processed within a day after collection. The cheese wheels are then soaked in a brine bath for 20-25 hours before being transferred to an aging facility for at least 12 months. After this period, each wheel is hand-inspected by a master grader, and if it passes, its rind is branded with the consortium's insignia.

Reggian cheese has a complex, granular texture and a rich, sharp flavor. It is known for its savory depth and notes of toasted nuts, caramel sweetness, and umami.