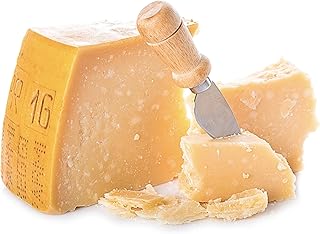

Parmesan cheese, or Parmigiano Reggiano, is a hard, granular Italian cheese made from cow's milk and aged for at least 12 months. The process of making Parmesan cheese involves combining whole milk and naturally skimmed milk, which is then heated in copper vats. During this two-step heating process, additional ingredients like whey and rennet are added to form the curd. The cheese is then aged in the copper vats to create a distinct sweet taste through the natural fermentation of cow's milk. In this response, we will delve into the intricacies of crafting this beloved cheese, exploring the traditional techniques and ingredients that contribute to its unique flavour and texture.

How Parmigiano Cheese is Made

| Characteristics | Values |

|---|---|

| Type of Milk | Cow's milk |

| Milk Temperature | 91-93F |

| Milk Pasteurization | 176 degrees for 15 seconds |

| Aging Time | 6+ months for authentic flavor; 10+ months for US production; 9+ months for Grana Padano; 12+ months for traditional Parmigiano |

| Aging Place | Northern Italy |

| Additional Ingredients | Whey, rennet, calcium chloride |

| Texture | Hard, granular |

| Color | Pale yellow |

Explore related products

What You'll Learn

Parmigiano Reggiano is a protected designation of origin (PDO)

The strict rules governing the production of Parmigiano Reggiano PDO ensure that the cheese is made only with raw milk from the area of origin and that the traditional processing techniques are followed. This includes the role of the cheese master, who enhances and favors the lactic bacteria necessary for successful cheese making. The designation also means that only cheeses bearing the PDO label "Parmigiano Reggiano" can be sold under the denomination "parmesan".

The protection of Parmigiano Reggiano's geographical origin is so stringent that even if the same production techniques were used elsewhere, the product could not be called Parmigiano Reggiano. This is because the unique microbiological characteristics of the designated area give the cheese its distinctive qualities. The European Court of Justice ruled in 2008 that the use of the term "parmesan" to describe non-Italian hard and grated cheeses is not compliant with the production specifications of Parmigiano Reggiano PDO and violates the EU's PDO regulations.

To combat fraudulent products on the market, which are estimated to make up 20-40% of grated "parmesan", scientists have developed methods to discriminate between authentic and non-authentic Parmigiano Reggiano. These methods, based on non-targeted mass spectrometry and chemometrics, can identify the geographical origin of the cheese by analyzing its chemical composition.

Cheese Whiz: What's in This Beloved, Cheesy Spread?

You may want to see also

Parmesan is made from cow's milk

Parmesan is a hard, granular Italian cheese, typically used grated on dishes such as pasta, Caesar salad, and pizza. It is traditionally made from cow's milk, with whole milk and naturally skimmed milk combined and heated in copper vats. The milk is heated to a specific temperature range of 91-93°F, with additional ingredients like whey and rennet added during the two-step heating process to form the curd.

The use of cow's milk is a key factor distinguishing Parmesan from other cheeses. For example, Pecorino cheese is made from sheep's milk, which contains more fat, while Romano cheese is made from cow's milk but is distinct from Parmesan in other ways. Parmesan's unique flavour and texture are due to the specific combination of ingredients and techniques used in its production.

The process of making Parmesan involves a two-step heating process, where the milk is heated slowly to the desired temperature. The addition of calcium chloride helps to regulate the milk's acidity and improve its texture. The milk is then combined with rennet, a natural enzyme found in the stomachs of young mammals, aiding in digesting their mother's milk. This combination forms the curd, which is then shaped and aged.

The aging process is crucial to the development of Parmesan's distinct flavour and texture. Traditionally, Parmesan is aged for at least 12 months, with some varieties aged for longer periods, up to 16 months, to create a sweeter taste through natural fermentation. The aging time and specific techniques used can vary depending on the region and the cheesemaker's traditions.

In conclusion, Parmesan is a unique and ancient cheese variety, renowned for its distinctive flavour and granular texture. The use of cow's milk, combined with specific production techniques and aging processes, contributes to its protected designation of origin (PDO) status. The traditional methods and high standards of Parmesan cheese-making have made it a widely imitated and regulated product, ensuring its authenticity and quality.

Limburger Cheese: US Production and History

You may want to see also

The cheese is aged for at least 12 months

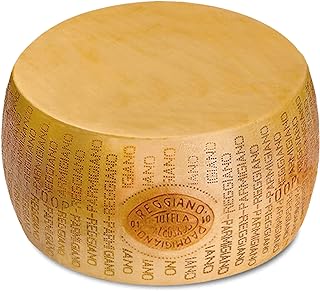

After the brining stage, Parmigiano Reggiano is transferred to the aging rooms in the plant for at least 12 months. Each cheese is placed on wooden shelves, with 2,160 wheels per aisle. Every seven days, each cheese and the shelf underneath it is cleaned, and the cheese is turned. At 12 months, the Consorzio del Formaggio Parmigiano Reggiano inspects the cheese.

The cheese is aged for a minimum of 12 months, but it can mature for much longer. It is worth seeking out Parmigiano Reggiano aged for 24 months, 36 months, 40 months, or even longer because the aroma, texture, and flavor evolve in the process. At 12 or 18 months, the cheese is more delicate, fresh, and milk-forward, but over time, its texture becomes crumbly and pleasantly grainy, while its aroma and flavor deepen with notes of spice and nuts. Parmigiano Reggiano aged for 12 or 18 months pairs well with sparkling and white wine, while Parmigiano Reggiano aged for 24 months or longer pairs well with red wine.

The aging process is one of the reasons for the rich flavor and granular texture of Parmigiano Reggiano. The cheese has a sharp, complex fruity and nutty taste with a strong savory flavor and a slightly gritty texture. Its aroma is fragrant and spicy but not piquant. The complex flavor and extremely granular texture are a result of the long aging.

In the United States, the word "Parmesan" is not regulated, and most American versions of the cheese age for a minimum of 10 months. However, within the European Union, the term Parmesan may only be used, by law, to refer to Parmigiano Reggiano itself, which must be made in a restricted geographic area, using stringently defined methods.

Cheese Making Process: From Milk to Deliciousness

You may want to see also

Explore related products

Rennet is added to form the curd

When making Parmigiano cheese, the milk is heated slowly to a specific temperature range of 91-93°F (32.8-33.9°C). This temperature is carefully maintained to create the ideal environment for the rennet to work effectively. The milk is combined with other ingredients, such as calcium chloride, and placed in a water bath or heated directly on a stovetop.

The addition of rennet causes the milk to coagulate and form a solid mass, known as the curd. This curdling process is essential for separating the solids from the liquids in the milk. The curd is then cut and stirred, releasing moisture and forming smaller curds, which eventually knit together into a solid mass.

The amount of rennet added and the coagulation time can vary depending on the quality and type of milk used. For example, if using raw milk, a decrease in rennet concentration (by 25-30%) and a shorter coagulation time (by 40-50%) are recommended. Adjustments like these ensure the desired curd formation and ultimately affect the texture and quality of the final cheese product.

Cheese Without Milk: Is It Possible?

You may want to see also

The milk is heated in copper vats

The copper vats are an integral part of the process, as they not only heat the milk but also contribute to the flavour of the cheese. The milk is then heated for a second time, and it is during this step that additional ingredients are added to form the curd. These include whey and rennet, a natural enzyme found in the stomachs of young mammals, which helps them digest their mother's milk. The rennet is essential to the process, as it causes the milk to curdle and form the curd.

The milk mixture is carefully heated and stirred, ensuring the temperature is just right, and the ingredients are fully incorporated. The milk is then ready for the next stage of the process, where it will begin to transform into the solid cheese we know as Parmigiano. The heating process is critical, as it causes the milk proteins to denature and form the curd, which is the solid mass that will become the cheese.

The copper vats are used because copper is an excellent conductor of heat, ensuring the milk is heated evenly and efficiently. This even heating is essential to the cheese-making process, as it ensures the milk is not overheated or scorched, which would affect the flavour and quality of the final product. The vats are carefully cleaned and sanitised before use, ensuring no bacteria or contaminants affect the milk during this critical stage.

Brie Cheese Rinds: Unraveling Their Composition and Edibility

You may want to see also

Frequently asked questions

Parmigiano Reggiano is the Italian name for Parmesan cheese. It is named after the provinces of Parma and Reggio Emilia, where it is produced.

Parmigiano Reggiano is typically aged for at least 12 months. However, some varieties are aged for longer, up to 16 months, to create a sweeter flavour.

Parmigiano Reggiano is traditionally made from cow's milk. Additional ingredients like whey and rennet are added during the heating process to form the curd.