The creation of Camembert cheese is often attributed to Marie Harel, a farmer and cheesemaker from Normandy, France. According to local legend, Harel developed the cheese-making process with the help of Abbot Charles-Jean Bonvoust, a priest who took refuge at her farm while fleeing the anti-clerical French Revolution in 1790. Bonvoust shared his knowledge of cheesemaking, particularly the techniques for creating soft, bloomy-rind cheeses like Brie, with Harel. She then adapted these methods to suit the local milk produced in Normandy, resulting in a unique cheese with a creamy texture and distinct aroma.

| Characteristics | Values |

|---|---|

| Inventors | Marie Harel and Abbot Charles-Jean Bonvoust |

| Marie Harel's profession | Cheese maker, dairymaid |

| Year of invention | 1791 |

| Place of invention | Camembert, Normandy, France |

| Cheese type | Soft, creamy, surface-ripened cow's milk cheese |

| Cheese shape | Small round cheese |

| Cheese size | 10.2 cm (4 in) in diameter by 3.2 cm (1.26 in) in thickness |

| Cheese colour | Ivory to light yellow |

| Cheese texture | Smooth and soft |

| Cheese flavour | Slightly salty, milky, mild, fruity, earthy aroma, creamy taste |

| Cheese packaging | Thin, round, wooden containers |

| Cheese production | Made from raw, unpasteurized milk from Normandes cows |

| Cheese distribution | Distributed to French troops during World War I |

Explore related products

What You'll Learn

- Marie Harel, a farmer and cheese maker, is credited with creating Camembert cheese

- Priest Abbot Charles-Jean Bonvoust taught Harel how to make the cheese

- Bonvoust was seeking refuge from the French Revolution at Harel's farm

- Bonvoust instructed Harel on the use of Penicillium mould in cheesemaking

- Camembert was first made in the late 18th century in the village of Camembert, Normandy

Marie Harel, a farmer and cheese maker, is credited with creating Camembert cheese

Marie Harel, born Marie Catherine Fontaine, is credited with creating Camembert cheese. She was a farmer and cheese maker from Normandy, France. According to local legend, Harel developed the cheese in 1791, at the height of the French Revolution, with the help of Abbot Charles-Jean Bonvoust, a refractory priest whom she was hiding on her farm.

Harel is said to have made slight adaptations to the recipe she learned from Bonvoust, including removing the cream and making the cheese in smaller wheels. She also packaged the cheese in thin, round, wooden containers. This innovation in packaging, along with the invention of mass-produced round wooden boxes, helped Camembert cheese maintain its freshness when it was issued to French troops during World War I.

Camembert was first made in the late 18th century in the village of Camembert, Normandy, in northwest France. It is a soft, creamy, surface-ripened cow's milk cheese with a distinctive earthy aroma and edible white rind. The cheese was named after the village of Camembert, and it became famous in 1863 when Napoleon III inaugurated the railway line between Paris and Granville. During a stopover in Surdon, Harel's grandson offered him a taste of the cheese, and the Emperor was so impressed that he regularly ordered it to be served at the Tuileries Palace.

In recognition of her contribution to the world of cheese, Harel's hometown of Vimoutiers erected a statue in her honour in 1856. Her work also inspired a dynasty of entrepreneurial cheese makers, including her grandson Cyrille Paynel, who produced Camembert on a large scale. Today, Camembert is internationally known, with many local varieties produced around the world.

Gournay Cheese: A Blend of Cream and Fresh Herbs

You may want to see also

Priest Abbot Charles-Jean Bonvoust taught Harel how to make the cheese

Marie Harel, born Marie Catherine Fontaine, was a French cheesemaker from Normandy. She was born on April 28, 1761, and died on November 9, 1844. Her family was long known for their cheesemaking in the region. However, it was only when she was taught by Priest Abbot Charles-Jean Bonvoust that she created Camembert cheese.

According to local legend, Bonvoust, a refractory priest fleeing the anti-clerical French Revolution, took refuge in Harel's home in 1790. During his stay, he taught Harel the Brie-making process, which he had learned as a cheesemaker. With this knowledge, Harel developed her own unique style of cheese. She made some slight adaptations to the recipe, including removing the cream and making the cheese in smaller wheels. Smaller wheels allowed for a more efficient supply chain and gave the cheese a slightly stronger flavour compared to Brie.

Harel's cheese provided a more "earthy aroma, creamy taste, and edible white rind." It was made purely from raw cow's milk rather than a cream additive. The cheese was first produced in 1791, at the height of the French Revolution. It was created through a transfer of skills between Bonvoust and Harel, who was hiding him on her farm.

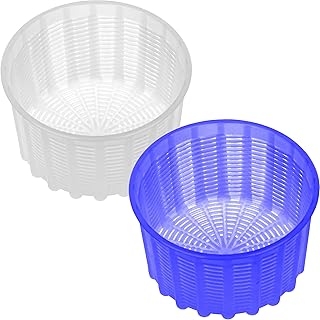

The process of making Camembert cheese involves inoculating warmed cow's milk with mesophilic bacteria and then adding rennet to allow the mixture to coagulate. The curd is then cut into cubes, salted, and transferred to low cylindrical camembert moulds. The cheese is then left to drain and salted again before being dried. It then begins the ripening process, during which it develops its characteristic white rind due to the formation of penicillium on the surface. After 12 days, the cheese is transferred to a maturing cellar, where it continues to ripen for another week before being tasted.

Tasmanian Heritage Cheese: Where is it Made?

You may want to see also

Bonvoust was seeking refuge from the French Revolution at Harel's farm

In 1790, during the French Revolution, Abbot Charles-Jean Bonvoust, a priest from Brie, sought refuge at the Harel farm in the village of Camembert, Normandy. The priest was fleeing the anti-clerical sentiment of the time. Marie Harel, a 30-year-old farmer and dairymaid, lived and worked on the farm with her family.

The Harel family were well-known cheesemakers in the region. Marie Harel had been learning the art of cheesemaking from her mother since she was a young girl. Bonvoust, himself a cheesemaker, taught Harel his technique for making soft, bloomy-rind cheeses, similar to those from his native Brie region. He shared his knowledge of the Brie-making process with Harel, who then carefully developed her own version of the recipe.

One key lesson the priest imparted was the use of Penicillium mould in cheesemaking, which was already used in Brie production. Harel combined this new knowledge with her own expertise. She used local milk from Normandy and adapted the methods to suit the region's conditions. This combination gave birth to what we now know as Camembert cheese.

Harel's new cheese had a rich, creamy taste and a soft texture, which was unique in Normandy at the time. Initially, her neighbours were not impressed by the cheese, but eventually, some gave it a try, and word of the new cheese began to spread. Camembert was soon being sold in markets beyond the village of Camembert, and it was named after the village.

The Mystery of Fake Cheese: What's It Made Of?

You may want to see also

Explore related products

Bonvoust instructed Harel on the use of Penicillium mould in cheesemaking

According to local legend, Marie Harel, a then 30-year-old dairymaid from Vimoutiers, Normandy, was taught how to make Camembert cheese by a priest, Abbot Charles-Jean Bonvoust, who was seeking refuge from the anti-clerical French Revolution. Marie Harel's family had been long known for their cheesemaking in the Normandy region, and she is said to have made some slight adaptations to the recipe, including removing cream, making them in smaller wheels, and packaging the cheese in thin, round wooden containers.

While the sources do not explicitly state that Bonvoust instructed Harel on the use of Penicillium mould in cheesemaking, it is known that Camembert cheese gets its characteristic white rind from the penicillium that develops on its surface during the ripening process. Therefore, it can be inferred that Bonvoust, an experienced cheesemaker himself, would have instructed Harel on the role of Penicillium mould in creating this distinctive rind.

The use of mould in cheesemaking, particularly the Penicillium species, is a well-known technique that has been used for centuries. Penicillium mould plays a crucial role in the ripening and flavour development of cheese. In the case of Camembert, the mould contributes to the formation of its white rind, which is a defining feature of this cheese variety. The rind not only gives Camembert its unique appearance but also influences its texture and flavour.

During the ripening process, the penicillium mould grows on the surface of the cheese, breaking down some of the curds and contributing to the creamy texture characteristic of Camembert. Additionally, the mould facilitates the development of complex flavours, adding depth and a slight earthiness to the cheese. This process is essential in transforming the young, mild cheese into a more mature, flavourful product.

Overall, while the exact details of Bonvoust's instructions to Harel may not be known, it is safe to assume that, as an experienced cheesemaker, he would have imparted his knowledge of the Brie-making process, including the use of Penicillium mould, allowing Harel to create her own distinctive variety of cheese, now known and beloved as Camembert.

Hot Cheetos: Cheese or Not?

You may want to see also

Camembert was first made in the late 18th century in the village of Camembert, Normandy

According to local legend, Camembert cheese was first produced in 1791 at the height of the French Revolution. The recipe was developed by Marie Harel, a then 30-year-old dairymaid from Vimoutiers, Normandy, with the help of Abbot Charles-Jean Bonvoust, a refractory priest who was fleeing the anti-clerical French Revolution. Marie Harel's family had been long known for their cheesemaking in the Normandy region, and she made some slight adaptations to the recipe, including removing cream, making the cheeses in smaller wheels, and packaging them in thin, round wooden containers.

The cheese is made by inoculating warmed cow milk with mesophilic bacteria, then adding rennet and allowing the mixture to coagulate. The curd is then cut into roughly 1 cm (1/2 inch) cubes, salted, and transferred to low cylindrical Camembert moulds. The Camembert cheeses will drain naturally for almost 18 hours. The Camembert will then be salted, dried, and they can begin their ripening process. On day four of ripening, the Camemberts release a sweet smell of apples, a sign of great quality. After 12 days, they will be transferred to the maturing cellar, and it will take another week of ripening before the first Camembert cheeses will be tasted.

Camembert became famous in 1863 when Napoleon III inaugurated the railway line between Paris and Granville. During a stopover in Surdon, Marie Harel’s grandson gave him a taste of this precious cheese. It is said that the Emperor asked her grandson for the name of the cheese, and when he didn’t know, the Emperor suggested the name Camembert. He then regularly ordered Camembert to be served at the Tuileries Palace. In 1914, during World War I, Camembert cheese was part of the wartime ration of French soldiers who ate it on the front line.

The Making of Fat-Free Feta Cheese

You may want to see also

Frequently asked questions

Priest Bonvoust, whose real name was Abbot Charles-Jean Bonvoust, taught Marie Harel how to make Camembert cheese. He was fleeing the anti-clerical French Revolution and took refuge at her farm.

Marie Harel was a cheese maker and, according to local legend, she made some slight adaptations to the recipe Bonvoust taught her. This included removing cream, making the wheels of cheese smaller, and packaging the cheese in thin, round, wooden containers.

Camembert is a soft, creamy, surface-ripened cow's milk cheese. It was first made in the late 18th century in Camembert, Normandy, in northwest France. The first Camembert was made from unpasteurized milk, and the AOC variety "Camembert de Normandie" is required by law to be made only with unpasteurized milk.