The evolution of cheese packaging reflects both technological advancements and changing consumer needs. Initially, cheese was wrapped in natural materials like leaves, bark, or animal skins to preserve it and protect it from contaminants. As civilizations progressed, wax coatings became popular for their ability to create a moisture barrier while allowing the cheese to breathe. The Industrial Revolution introduced tin foil and parchment paper, offering more consistent protection. In the 20th century, plastic films and vacuum-sealed packaging revolutionized the industry by extending shelf life and reducing spoilage. Today, modern packaging includes modified atmosphere packaging (MAP) and biodegradable materials, balancing preservation with sustainability, while also addressing convenience and branding demands in a competitive market.

| Characteristics | Values |

|---|---|

| Material | Plastic (e.g., polyethylene, polypropylene), wax, parchment paper, foil, vacuum-sealed bags, biodegradable packaging |

| Type of Packaging | Blocks, slices, shredded, wedges, wheels, vacuum-sealed packs, flow-wrap, shrink-wrap, modified atmosphere packaging (MAP) |

| Protection | Moisture barrier, oxygen barrier, UV protection, tamper-evident seals |

| Shelf Life | Extended due to vacuum sealing, MAP, and airtight packaging |

| Portion Control | Pre-sliced, individually wrapped portions |

| Sustainability | Biodegradable materials, recyclable plastics, reduced packaging waste |

| Labeling | Nutritional information, expiration date, brand details, QR codes |

| Convenience | Reclosable packaging, easy-tear features, stackable designs |

| Aesthetic Appeal | Transparent windows, branded designs, premium finishes |

| Temperature Control | Insulated packaging for refrigerated transport |

| Regulatory Compliance | Meets food safety standards (e.g., FDA, EU regulations) |

| Cost-Effectiveness | Lightweight materials to reduce shipping costs |

| Customization | Brand-specific shapes, sizes, and designs |

Explore related products

$8.99 $9.99

What You'll Learn

- Early Cheese Packaging Methods: Simple wraps using leaves, cloths, or animal skins for preservation and transport

- Industrial Revolution Impact: Introduction of wax coatings, tins, and paper for mass production and distribution

- Modern Plastic Wrapping: Use of polyethylene and vacuum sealing to extend shelf life and ensure freshness

- Eco-Friendly Packaging Trends: Adoption of biodegradable materials like waxed paper and plant-based films for sustainability

- Specialty Cheese Packaging: Wooden boxes, parchment, and breathable films to maintain texture and flavor in artisanal cheeses

Early Cheese Packaging Methods: Simple wraps using leaves, cloths, or animal skins for preservation and transport

Before the advent of modern packaging materials, early cheese makers relied on nature’s bounty to preserve and transport their craft. Leaves, cloths, and animal skins were the primary tools of the trade, each offering unique benefits for protection and aging. These methods were not just practical; they were deeply intertwined with the cultural and environmental contexts of the time. For instance, grape leaves in the Mediterranean and banana leaves in tropical regions were chosen for their availability and natural antimicrobial properties, which helped extend cheese shelf life.

Consider the process of wrapping cheese in leaves: it was both an art and a science. Leaves like fig or chestnut were selected for their toughness and ability to repel moisture, while softer leaves like cabbage were used for more delicate cheeses. The wrapping technique mattered—layers were often folded tightly to create a barrier against air and pests, yet breathable enough to allow the cheese to mature. This method was particularly effective for semi-hard cheeses, which required controlled exposure to air for proper aging. A practical tip: when replicating this method today, ensure leaves are thoroughly cleaned and dried to prevent mold growth.

Cloth wrapping, another ancient technique, offered versatility and reusability. Linen or cotton cloths were soaked in brine or wine before use, adding flavor and creating a humid microenvironment that prevented the cheese from drying out. This method was ideal for softer cheeses like Brie or Camembert, which needed protection without complete sealing. However, cloths required regular maintenance—washing and re-treating with brine—to avoid bacterial buildup. For home cheesemakers, using food-grade muslin and rotating cloths between uses can mimic this traditional approach effectively.

Animal skins, though less common today, were prized for their durability and insulating properties. Skins from sheep or goats were cleaned, cured, and sometimes smoked to create a natural wrapper that could withstand long journeys. This method was particularly useful for hard cheeses like Pecorino, which could age for months without spoiling. The skin’s natural fats also imparted a subtle flavor, enhancing the cheese’s complexity. While modern regulations limit the use of untreated animal products, this method highlights the ingenuity of early preservation techniques.

Comparing these methods reveals a balance between resourcefulness and functionality. Leaves provided natural protection and flavor enhancement, cloths offered flexibility and moisture control, and skins ensured durability for long-term storage. Each material was chosen not just for its availability but for its ability to interact with the cheese in beneficial ways. For enthusiasts looking to experiment, combining these techniques—such as wrapping cheese in a brine-soaked cloth and then enclosing it in leaves—can yield unique results. The takeaway? Early packaging methods were not just about preservation; they were about enhancing the cheese’s character through thoughtful material selection and craftsmanship.

The Crunchy Creation: Unraveling the Story Behind Cheese Curls

You may want to see also

Industrial Revolution Impact: Introduction of wax coatings, tins, and paper for mass production and distribution

The Industrial Revolution transformed cheese packaging from a localized, artisanal process into a standardized, scalable system. Before this era, cheese was often wrapped in cloth or stored in wooden containers, methods that limited shelf life and hindered long-distance distribution. The introduction of wax coatings, tins, and paper during the 19th century marked a pivotal shift, enabling mass production and broader accessibility. Wax coatings, for instance, provided a protective barrier against moisture and mold, extending the cheese’s freshness. Tins, with their durability and airtight seals, became ideal for transporting cheese over long distances, while paper offered a lightweight, cost-effective solution for wrapping individual portions. These innovations not only preserved quality but also democratized cheese consumption, making it a staple in households far beyond its place of origin.

Consider the practical application of wax coatings, a technique still used today for cheeses like Cheddar and Gouda. During the Industrial Revolution, wax was applied in thin, even layers using newly developed machinery, ensuring consistency across large batches. This method not only protected the cheese but also allowed for branding and labeling directly on the wax surface. For home use, replicating this process involves melting food-grade wax to 140–150°F (60–65°C) and brushing it onto the cheese in multiple coats, ensuring full coverage. While modern wax is often removed before consumption, historically, it served as both preservation and presentation, showcasing the cheese’s quality to consumers.

Tins revolutionized cheese distribution by addressing the logistical challenges of the time. The mid-1800s saw the rise of tin canning, a process initially developed for preserving foods like meat and vegetables. Cheese manufacturers quickly adopted tins, particularly for softer varieties like cream cheese and processed blends. Tins provided an airtight environment, preventing spoilage during transport, and their stackable design optimized storage and shipping. For example, the iconic "Kraft Cheese Tin" became a household staple in the early 20th century, symbolizing convenience and reliability. Today, while tins are less common for cheese packaging, their legacy endures in the design of modern containers that prioritize durability and portability.

Paper packaging emerged as a versatile solution for the growing demand for pre-portioned cheese. The Industrial Revolution’s advancements in paper production made it an affordable and readily available material. Waxed paper, introduced in the late 1800s, combined the benefits of paper’s flexibility with wax’s protective properties, becoming a standard for wrapping individual cheese slices. This innovation was particularly beneficial for urban populations, who sought convenient, ready-to-eat options. For those looking to adopt sustainable practices, modern alternatives like compostable paper or plant-based wax coatings offer eco-friendly options without sacrificing functionality.

The cumulative impact of these packaging innovations cannot be overstated. Wax coatings, tins, and paper not only preserved cheese but also transformed it into a commodity that could be mass-produced and distributed globally. These methods laid the foundation for the modern cheese industry, where packaging is as critical as the product itself. For enthusiasts and professionals alike, understanding this history provides valuable insights into the balance between tradition and innovation. Whether you’re a small-scale producer or a consumer, incorporating these time-tested techniques—or their modern equivalents—can enhance both the quality and sustainability of cheese packaging.

Cheesy Nachos Decoded: Unveiling the Ounce Count in Restaurant Orders

You may want to see also

Modern Plastic Wrapping: Use of polyethylene and vacuum sealing to extend shelf life and ensure freshness

Polyethylene, a lightweight and durable plastic, has revolutionized cheese packaging by offering a cost-effective barrier against moisture and oxygen. Its low permeability to gases helps slow down the growth of bacteria and mold, significantly extending the shelf life of cheese. For instance, semi-hard cheeses like cheddar, when wrapped in polyethylene, can maintain freshness for up to 8 months under proper storage conditions. This material’s versatility allows it to be used in various forms, from shrink wraps to vacuum-sealed bags, catering to different cheese types and packaging needs.

Vacuum sealing, often combined with polyethylene, takes freshness preservation a step further by removing air from the package. This process inhibits aerobic bacteria and slows enzymatic activity, which are primary causes of spoilage. For soft cheeses like Brie or Camembert, vacuum sealing can double their shelf life from 2–3 weeks to 4–6 weeks. To achieve optimal results, ensure the cheese is wrapped tightly in polyethylene before vacuum sealing to prevent punctures or leaks. This dual-layer approach is particularly effective for artisanal cheeses, where maintaining texture and flavor is critical.

While polyethylene and vacuum sealing are highly effective, their environmental impact cannot be ignored. Polyethylene is a non-biodegradable plastic, contributing to waste accumulation. However, advancements like biodegradable polyethylene (bio-PE) offer a sustainable alternative without compromising performance. For home users, reusable vacuum sealers and biodegradable wraps are practical options to reduce waste. Commercially, adopting bio-PE for cheese packaging aligns with growing consumer demand for eco-friendly solutions, making it a win-win for both preservation and sustainability.

When implementing modern plastic wrapping techniques, consider the cheese’s moisture content and intended storage duration. High-moisture cheeses like mozzarella benefit from thicker polyethylene layers to prevent moisture loss, while harder cheeses like Parmesan require minimal wrapping to allow gradual drying. Always store vacuum-sealed cheese in a cool, dark place, ideally at temperatures between 2–8°C (36–46°F). For retailers, labeling packages with clear storage instructions and expiration dates ensures consumers maintain the cheese’s quality at home. By mastering these techniques, both producers and consumers can enjoy cheese that stays fresher, longer.

Mastering the Art of Slicing Frozen Cheese Without Crumbling

You may want to see also

Explore related products

Eco-Friendly Packaging Trends: Adoption of biodegradable materials like waxed paper and plant-based films for sustainability

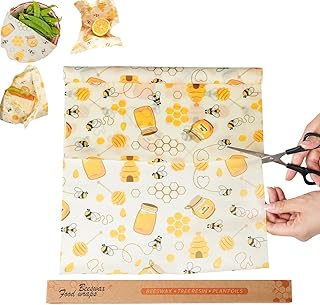

Cheese packaging has traditionally relied on plastic films and coatings, contributing significantly to environmental waste. However, a shift toward eco-friendly alternatives is gaining momentum, driven by consumer demand and regulatory pressures. Biodegradable materials like waxed paper and plant-based films are emerging as viable solutions, offering both sustainability and functionality. These materials decompose naturally, reducing the long-term environmental impact associated with conventional packaging. For instance, waxed paper, derived from natural sources like soy or beeswax, provides a moisture-resistant barrier suitable for cheese while being fully compostable. Similarly, plant-based films, often made from polylactic acid (PLA) derived from corn starch, offer transparency and flexibility comparable to plastic but with a significantly lower carbon footprint.

Adopting these materials requires careful consideration of their properties and limitations. Waxed paper, for example, excels in breathability, which can help regulate cheese moisture levels, but it may not provide the same oxygen barrier as synthetic films. Plant-based films, on the other hand, can be engineered to enhance barrier properties, making them suitable for longer shelf life applications. However, their cost remains higher than traditional plastics, posing a challenge for widespread adoption. Manufacturers must balance these trade-offs, potentially combining materials or optimizing designs to maximize sustainability without compromising product quality.

From a practical standpoint, transitioning to biodegradable packaging involves several actionable steps. First, assess the specific needs of the cheese type—hard cheeses may require less moisture protection than soft varieties. Second, collaborate with suppliers to source certified biodegradable materials, ensuring they meet food safety standards. Third, educate consumers on proper disposal methods, as many biodegradable materials require industrial composting facilities to break down effectively. For example, PLA films should be labeled with clear disposal instructions to avoid contamination in recycling streams.

The benefits of this shift extend beyond environmental impact. Brands adopting eco-friendly packaging can differentiate themselves in a competitive market, appealing to sustainability-conscious consumers. A study by Nielsen found that 73% of global consumers would pay more for sustainable products, highlighting the potential for premium pricing. Additionally, regulatory incentives and consumer packaging taxes in some regions can offset the higher costs of biodegradable materials.

In conclusion, the adoption of biodegradable materials like waxed paper and plant-based films represents a critical step toward sustainable cheese packaging. While challenges remain, the combination of consumer demand, technological advancements, and strategic implementation makes this trend both feasible and impactful. By prioritizing sustainability without sacrificing functionality, the cheese industry can lead the way in reducing packaging waste and fostering a greener future.

Wisconsin's 1874 Cheese Legacy: Unveiling the Iconic Brick Cheese

You may want to see also

Specialty Cheese Packaging: Wooden boxes, parchment, and breathable films to maintain texture and flavor in artisanal cheeses

Artisanal cheeses demand packaging that preserves their delicate textures and complex flavors, a challenge that has spurred innovation in materials and design. Wooden boxes, parchment, and breathable films have emerged as key solutions, each offering unique benefits for specialty cheese preservation. Wooden boxes, often crafted from pine or cedar, provide a natural, moisture-regulating environment that prevents excessive drying while allowing cheeses to breathe. The wood’s porous structure mimics traditional aging conditions, making it ideal for hard and semi-hard varieties like Parmigiano-Reggiano or aged Goudas. However, wooden packaging is costly and best suited for premium products or aging in cellars rather than retail display.

Parchment paper, another traditional material, serves as a protective barrier that minimizes moisture loss while allowing gases to escape, crucial for cheeses like Brie or Camembert that require specific humidity levels to develop their signature rinds. Its grease-resistant properties also prevent oils from seeping through, maintaining both the cheese’s integrity and the packaging’s appearance. For optimal use, wrap cheeses loosely in parchment to avoid trapping excess moisture, and pair it with an outer layer of breathable film for added protection during transport. This combination is particularly effective for soft-ripened cheeses, where texture and aroma are paramount.

Breathable films, such as micro-perforated plastic or biopolymer wraps, represent a modern solution that balances protection with gas exchange. These films are engineered to allow oxygen and carbon dioxide to pass through at controlled rates, supporting the natural aging process while preventing mold or bacterial contamination. For example, a semi-hard cheese like Gruyère wrapped in breathable film can maintain its open texture and nutty flavor profile for weeks. When selecting breathable films, consider the cheese’s moisture content and desired ripening speed—higher moisture cheeses require more permeable materials.

Combining these materials can yield superior results. A wooden box lined with parchment and sealed with breathable film creates an optimal microclimate for aging, blending tradition with technology. This approach is especially valuable for small-batch producers aiming to differentiate their products in a competitive market. However, it requires careful calibration: too much breathability can lead to rapid drying, while too little stifles flavor development. Producers should test packaging combinations under real-world conditions to ensure consistency across batches.

Ultimately, the choice of packaging depends on the cheese’s characteristics and intended shelf life. Wooden boxes excel for long-term aging, parchment suits soft cheeses needing humidity control, and breathable films offer versatility for various types. By understanding these materials’ strengths and limitations, artisanal cheesemakers can craft packaging that not only protects their product but also enhances its sensory experience, reinforcing the craftsmanship behind every wheel or wedge.

Mastering Madden 20 Defense: Strategies to Counter 49ers Run Cheese

You may want to see also

Frequently asked questions

Traditionally, cheese was packaged using natural materials such as leaves, bark, or animal skins to protect it from spoilage. For example, cheeses like Edam and Gouda were often wrapped in wax-coated paper or cloth.

In the early 20th century, cheese was commonly packaged in waxed paper, parchment, or tin foil. Wooden boxes were also used for larger blocks of cheese, especially for shipping and storage.

Modern cheese packaging uses materials like plastic films, vacuum-sealed pouches, and modified atmosphere packaging (MAP) to extend shelf life and maintain freshness. Innovations like biodegradable and recyclable materials are also becoming more common for sustainability.