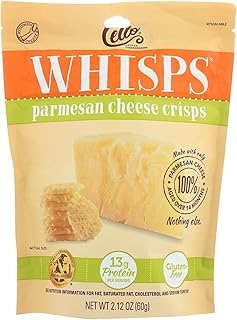

Whisps Cheese Crisps are a popular snack food made from 100% real cheese. They are baked into light, crispy, and flavorful snacks, providing a healthy alternative to potato chips. Whisps are gluten-free, keto-friendly, and high in protein, making them a popular choice for those on low-carb diets. The crisps come in a variety of flavors, including Parmesan, Cheddar, Asiago, and Pepper Jack, and can be enjoyed straight from the bag or as a topping on soups, salads, or appetizers. In this paragraph, we will explore the process of how Whisps Cheese Crisps are made, from the artisanal crafting of the cheese to the baking process that transforms it into a crispy, cheesy snack.

| Characteristics | Values |

|---|---|

| Ingredients | 100% "wheel" cheese |

| Preparation | Master cheesemakers craft artisanal cheeses, grate them, and bake them into light, flavorful crisps |

| Nutritional Information | High protein, low carb, gluten-free, keto-friendly, sugar-free, lactose-free |

| Taste | Rich, nutty, fruity |

| Texture | Crispy, crunchy |

Explore related products

What You'll Learn

Whisps are made from 100% wheel cheese

Whisps are made from 100% real "wheel" cheese. Master cheesemakers craft artisanal cheeses, which are then baked into light, flavourful crisps. This process results in a snack that is deliciously low carb, high in protein, and gluten-free. Whisps are available in a variety of flavours, including Parmesan, Cheddar, Asiago, and Pepper Jack.

The process of making Whisps starts with award-winning Parmesan, made the old-world way in copper kettles. This cheese is then aged for over a year, grated, and baked to create the rich, nutty, and fruity taste of Parmesan Whisps. Similarly, the Cheddar Whisps start with 100% perfectly aged cheddar, which is then baked to achieve a savoury, toasty crunch.

The Whisps brand is committed to using only 100% real cheese in their products, ensuring a delicious and satisfying snack experience. The cheese used in Whisps is sourced from local farms, providing premium milk that is rBGH and rBST-free. This commitment to quality and real ingredients sets Whisps apart as a trusted and nutritious snack option.

In addition to their delicious taste and satisfying crunch, Whisps offer several nutritional benefits. As a high-protein and low-carb snack, they are keto-friendly and can be enjoyed as a healthier alternative to traditional chips or croutons. Whisps are also gluten-free, sugar-free, and lactose-free, making them accessible to those with dietary restrictions.

Overall, Whisps are a unique and innovative snack option, made from 100% wheel cheese and baked to perfection. They offer a playful and delicious way to enjoy the goodness of real cheese, whether as a standalone snack or as a tasty addition to soups, salads, or appetizers.

Mac & Cheese: Wheat Pasta, Where's It Made?

You may want to see also

Master cheesemakers craft artisanal cheeses

Whisps are made from just one ingredient: 100% "wheel" cheese. The process begins with master cheesemakers crafting artisanal cheeses to perfection. This involves taking award-winning Parmesan, made the old-world way in copper kettles, and ageing it over a year. The aged cheese is then grated and baked to create Whisps' signature rich, nutty, and fruity flavour.

Master cheesemakers are experts in the art of cheese-making, possessing a deep understanding of the science and craft behind transforming milk into cheese. They carefully select the finest ingredients and employ traditional techniques to create artisanal cheeses with unique and distinct flavours, textures, and qualities.

The process of crafting artisanal cheeses is a meticulous and time-honoured tradition. It begins with the selection of high-quality milk, which can be sourced from cows, goats, or sheep. The milk is then carefully cultured with specific bacteria and coagulated with rennet, an enzyme derived from the stomachs of young ruminants. This crucial step causes the milk to curdle, separating it into solid curds and liquid whey.

Master cheesemakers then carefully cut and cook the curds, a process that helps expel more whey and contributes to the cheese's final texture. After this, the curds are placed in cheese moulds and pressed to form a cohesive mass. Salting is applied either during or after this pressing process, aiding in flavour development and preservation.

The final step in the cheesemaking process is ageing or ripening. Master cheesemakers carefully control temperature, humidity, and ventilation to create the ideal environment for the cheese to mature. During this ageing process, bacteria and enzymes work their magic, breaking down proteins and fats, developing complex flavours, and creating the distinctive characteristics of each artisanal cheese.

Cheddar Cheese Crafting: Enzymatic Artistry

You may want to see also

They are then baked into light, flavourful crisps

Whisps are made from just one ingredient: 100% "wheel" cheese. Master cheesemakers craft artisanal cheeses to perfection. They are then baked into light, flavourful crisps. This is done by grating the cheese and baking it to create a rich, nutty, fruity taste. Whisps are deliciously low carb, high protein, and gluten-free, making them a perfect snack for those who crave cheese. The cheese is baked until it reaches a savoury, toasty crunch.

Whisps come in a variety of flavours, including Parmesan, Cheddar, Asiago, and Pepper Jack. Each flavour is crafted from high-quality cheese and baked to perfection. The baking process transforms the cheese into a light and crispy texture, creating a satisfying snack experience.

The baking technique involves shredding or grating the cheese into fine pieces, similar to the preparation for frico, a traditional Italian cheese crisp. The shredded cheese is then spread thinly and evenly on a baking sheet, skillet, or air fryer basket. It is baked until the cheese melts and crisps up, forming a lacy texture with a golden brown colour.

The baking temperature and time may vary depending on the type of cheese and the desired crispness. However, the goal is to achieve a delicate balance where the cheese retains its shape enough to create a lacy pattern while melting sufficiently for the crisp to hold together. This balance is essential to achieving the light and flavourful texture that Whisps are known for.

In addition to the classic flavours, Whisps also offers innovative combinations such as Tomato Basil, which has been described as tasting and smelling like pizza. These flavour variations are created by adding ingredients such as sun-dried tomatoes, thyme, dried apples, or black pepper to the shredded cheese before baking. The versatility of Whisps allows them to be enjoyed as a standalone snack or as a topping on soups, salads, or sandwiches.

The Magic Behind Pwcorino Cheese: A Simple Guide

You may want to see also

Explore related products

Whisps are a keto-friendly snack

Whisps come in a variety of flavours, including Parmesan, Cheddar, Asiago, and Pepper Jack. They are a great alternative to traditional potato chips, which are often high in carbohydrates and unhealthy fats. Whisps are also a good option for those who are gluten intolerant or have celiac disease, as they are gluten-free.

The process of making Whisps involves crafting artisanal cheeses to perfection and then baking them into light and crispy snacks. This results in a product that is low in carbs and high in protein, making it an ideal snack for those on a keto diet.

The keto diet, or ketogenic diet, is a popular nutritional approach that involves reducing carbohydrate intake and increasing the consumption of healthy fats and proteins. This dietary shift encourages the body to burn fat for energy instead of carbohydrates, resulting in a state called ketosis. Whisps, with their high-fat and low-carb content, fit perfectly within the keto diet guidelines.

In addition to their nutritional benefits, Whisps are also praised for their taste and texture. Many customers enjoy the savoury, tangy, and salty flavour of the crisps, as well as the satisfying crunch they provide. Whisps can be enjoyed straight out of the bag or added to soups, salads, or appetizer plates. They are a versatile and delicious snack option that satisfies cheesy cravings while adhering to keto diet restrictions.

The Real Feta Cheese: A Simple Milk and Rennet Recipe

You may want to see also

They can be used as a substitute for croutons in salads or soups —although they may have an unfortunate effect on your digestive system

Whisps Cheese Crisps are a popular snack food made from 100% "wheel" cheese. They are baked into light, crispy, bite-sized snacks that are high in protein, gluten-free, and keto-friendly. Whisps come in a variety of flavours, including Parmesan, Cheddar, Asiago, and Garlic Herb. They are often marketed as a healthy alternative to potato chips, as they are low in carbs and made from real cheese.

While Whisps are a tasty and convenient snack option, they can also be used as an ingredient in other dishes. One popular way to use Whisps is as a substitute for croutons in salads or soups. The crispy texture and cheesy flavour of Whisps can add an interesting twist to traditional dishes. For example, Whisps can be crumbled over a salad to add a crunchy topping, or they can be sprinkled on top of a bowl of soup for a tasty garnish.

However, it is important to note that Whisps, like any other cheese product, may have an impact on your digestive system. Some people may find that consuming a large amount of Whisps in one sitting can lead to digestive issues. This is not uncommon with dairy products, as they can be difficult for some people to digest. It is always a good idea to consume Whisps in moderation and be aware of how your body reacts to them.

Additionally, Whisps are a high-fat and high-protein snack, so consuming too many of them may lead to excess calorie intake. As with any food, it is important to practise portion control and enjoy Whisps as part of a balanced diet. For those with dietary restrictions or sensitivities, it is also worth noting that Whisps are lactose-free, but they may contain other ingredients that could potentially trigger digestive issues in some individuals.

River Rat Cheese Curd: Where Is It Made?

You may want to see also

Frequently asked questions

Whisps Cheese Crisps are made from 100% "wheel" cheese.

Master cheesemakers first craft artisanal cheeses. Then they bake them into light, flavorful crisps.

There are several types of Whisps Cheese Crisps, including Parmesan, Cheddar, Asiago, and Pepper Jack.

Whisps Cheese Crisps are light, flavorful, low-carb, high-protein, and gluten-free. They are a great snack and can be added to soups, salads, or appetizer plates.