Blue cheese is a type of cheese with a distinct smell, taste, and appearance, characterised by its blue or blue-grey veins. It is made using a type of mould called Penicillium, which is added to the cheese after the curds have been drained and formed into wheels. The mould is responsible for the cheese's unique characteristics, and the process of making blue cheese involves six standard steps, with additional ingredients and processes to create its particular properties. This raises the question: is blue cheese binding?

| Characteristics | Values |

|---|---|

| Type of Cheese | Blue Cheese |

| Main Ingredient | Penicillium roqueforti |

| Other Ingredients | Milk, Salt, Sugar, Brevibacterium linens |

| Production Phases | 2 |

| Production Steps | 6 |

| Binding Type | Cohesive, Adhesive |

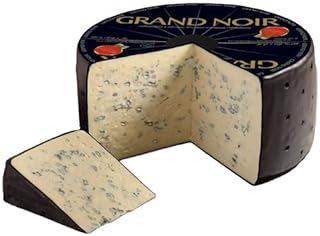

Explore related products

What You'll Learn

- Blue cheese is made using a type of mould called Penicillium

- Blue cheese is a general classification of cheeses with blue, or blue-grey mould

- Blue cheese is known for its strong smell and distinct flavour

- Blue cheese is aged in a temperature-controlled environment for 2-3 months

- Blue cheese can be eaten by itself or melted into or over foods, such as pizza

Blue cheese is made using a type of mould called Penicillium

Blue cheese is a type of cheese with a strong smell and distinct flavour. It is made using a type of mould called Penicillium, specifically Penicillium roqueforti. This mould is responsible for the cheese's unique taste, smell, and appearance, characterised by blue and green veins and spots. According to legend, one of the first blue cheeses, Roquefort, was discovered when a young boy's bread and ewes' milk cheese was left in a cave for months, allowing the mould to transform it into Roquefort.

Nowadays, the process of making blue cheese involves adding Penicillium roqueforti after the curds have been drained and formed into wheels. The mould can be sprinkled on top of the curds or injected into the cheese before the curds form. The cheese is then aged for 2-3 months in a temperature-controlled environment, such as a cave.

The use of Penicillium mould in blue cheese production is safe for human consumption. While certain types of mould produce toxic compounds called mycotoxins, the varieties of Penicillium used in cheesemaking do not produce these toxins. However, blue cheese can still spoil if not stored properly, so it is important to wrap it tightly and keep it refrigerated.

Overall, the mould Penicillium roqueforti plays a crucial role in giving blue cheese its distinctive characteristics, from its flavour and aroma to its visual appeal.

Blue Cheese Strain: Sativa or Indica?

You may want to see also

Blue cheese is a general classification of cheeses with blue, or blue-grey mould

Blue cheese is a type of cheese with a strong smell and distinct flavour. It is made using a type of mould called Penicillium, which is responsible for its characteristic taste, smell, and appearance. Blue cheese is a general classification of cheeses that have had cultures of the mould Penicillium added, resulting in a final product spotted or veined with blue or blue-grey mould.

The process of making blue cheese typically involves six standard steps, similar to other varieties of cheese, but additional ingredients and processes are required to achieve its unique properties. The first phase of production involves preparing a Penicillium roqueforti inoculum, which is then added to autoclaved, homogenised milk along with salt, sugar, or both. This mixture is incubated for several days, and the process is followed by whey drainage, salting, and finally, ripening the cheese through ageing.

Blue cheese has a long history, with Gorgonzola, one of the oldest known blue cheeses, dating back to around AD 879. Other well-known blue cheeses include Roquefort, which, according to legend, was discovered when a young boy left bread and ewes' milk cheese in a cave for months. Stilton, a relatively newer addition, gained popularity in the early 1700s, and many other varieties have since been created to meet the demand for these distinctive cheeses.

Blue cheese is typically aged in a temperature-controlled environment, such as a cave, and can be eaten on its own or spread, crumbled, or melted into or over foods. When properly stored, blue cheese can last 3-4 weeks in the refrigerator and can be frozen to extend its shelf life.

Blue Cheese Sauce: Perfect Pairing for Buffalo Wings?

You may want to see also

Blue cheese is known for its strong smell and distinct flavour

Blue cheese is a common type of cheese known for its strong smell and distinct flavour. It is made using cultures of Penicillium, a type of mould that's responsible for its unique taste, smell, and appearance. Unlike other types of mould, Penicillium does not produce toxins and is safe to consume. The mould spores are mixed in with the curds after they form, creating the blue, blue-grey, or green veins and spots that characterise blue cheese.

The process of making blue cheese consists of six standard steps, similar to other varieties of cheese. However, additional ingredients and processes are required to give this blue-veined cheese its particular properties. To begin with, the commercial-scale production of blue cheese consists of two phases: the culturing of suitable spore-rich inocula and fermentation for maximum, typical flavour. In the first phase of production, a Penicillium roqueforti inoculum is prepared. Multiple methods can be used to achieve this, but all involve the use of a freeze-dried Penicillium roqueforti culture.

Salt, sugar, or both are then added to autoclaved, homogenised milk via a sterile solution. This mixture is then inoculated with Penicillium roqueforti and incubated for three to four days at 21–25 °C (70–77 °F). More salt and/or sugar is added, and then aerobic incubation is continued for an additional one to two days. Alternatively, sterilised, homogenised milk and reconstituted non-fat solids or whey solids are mixed with sterile salt to create a fermentation medium. A spore-rich Penicillium roqueforti culture is then added, along with modified milk fat, which consists of milk fat with calf pre-gastric esterase. This solution is prepared in advance by an enzyme hydrolysis of a milk fat emulsion. The addition of modified milk fat stimulates a progressive release of free fatty acids, which is essential for rapid flavour development in blue cheese.

Once the curds have been formed, the Penicillium roqueforti inoculum is sprinkled on top, along with Brevibacterium linens. The curds are then knit in moulds to form cheese loaves with a relatively open texture. Whey drainage continues for 10–48 hours, with the moulds inverted frequently to promote this process. Salt is then added to provide flavour and act as a preservative through brine salting or dry salting for 24–48 hours. Finally, the cheese is ripened through ageing for 2–3 months. A fermentation period of 60–90 days is typically needed before the flavour of the cheese is typical and acceptable for marketing.

Melting Blue Cheese for Wings: Tips and Tricks

You may want to see also

Explore related products

Blue cheese is aged in a temperature-controlled environment for 2-3 months

Blue cheese is a beloved gourmet cheese with a pungent aroma and a unique flavour. Its production involves several steps, including the culturing of a suitable spore-rich inoculum and fermentation for maximum flavour. The process also involves the addition of specific ingredients and processes to give the cheese its characteristic blue veins and other properties.

One of the critical steps in crafting this cheese is ageing it in a temperature-controlled environment for 2-3 months. This ageing period, also known as ripening, allows the cheese to develop its signature flavour. During this time, the cheese transforms from having little to no blue cheese flavour to a typical and acceptable taste profile for marketing.

The ideal temperature range for ageing blue cheese is between 21-25°C (70-77°F) during the initial incubation phase. Subsequently, the temperature is lowered to below 40°F to prolong its freshness. Maintaining a stable temperature is crucial, and the bottom shelf or drawers of a refrigerator are ideal locations to achieve this.

The ageing duration for blue cheese can vary, with some sources recommending 60-90 days, while others suggest that it can be aged for up to 6 months. This variation in ageing time influences the flavour intensity and texture of the cheese.

Proper ageing and temperature control are essential for developing the complex flavours and textures that characterise blue cheese. This process transforms the cheese into a culinary delicacy enjoyed by connoisseurs worldwide.

Blue Cheese Fillet Mignon: Cooking a Decadent Steak

You may want to see also

Blue cheese can be eaten by itself or melted into or over foods, such as pizza

Blue cheese is a general classification of cheeses that have had cultures of the mold Penicillium added. This gives blue cheese its distinct smell, taste, and appearance, with blue, blue-grey, or green veins and spots. The mold is added to the cheese after the curds have been drained and rolled into wheels, and the cheese is then left to age for 2–3 months.

The binding properties of blue cheese are influenced by its molecular makeup, particularly the amount of moisture, casein proteins, and fats it contains. Excess moisture can hinder the formation of bonds between proteins, resulting in a runny or separated cheese. Therefore, it is important to control the melting process to achieve the desired binding characteristics.

Blue cheese can be spread, crumbled, or melted into or onto various dishes, adding its unique flavor and texture. It is a versatile cheese that can be enjoyed in many different ways, making it a popular choice for culinary creations.

Blue Cheese Conundrum: Hard or Not?

You may want to see also

Frequently asked questions

Blue cheese is a type of cheese made using cultures of Penicillium, a type of mold. It has a strong smell and distinct flavour.

Blue cheese is made by adding the mold Penicillium roqueforti to curds. The curds are then formed into a wheel of cheese, drained, and aged for 2-3 months.

Some varieties of blue cheese include Roquefort, Gorgonzola, Stilton, Danablu, and Cambozola.

Cheese binding occurs when cheese melts and forms a cohesive, stretchy substance. This is due to the rearrangement of casein proteins in the cheese as it melts.

Blue cheese has a similar binding mechanism to other cheeses. The type of binding depends on the amount of casein proteins, fats, and moisture present in the cheese. Blue cheese typically has a higher fat content, which can affect its binding properties.