Cheese wires are typically made of stainless steel and are used to cut through different types of cheeses. The thickness of the wire varies depending on the type of cheese being cut, with thicker wires being more suitable for harder cheeses. Cheese wires are designed to be strong, flexible, and corrosion-resistant to ensure smooth and precise cutting. Proper maintenance and care are important to prolong the life of cheese wires and ensure their effectiveness and safety.

| Characteristics | Values |

|---|---|

| Material | Stainless steel |

| Thickness | 0.25, 0.30, 0.40, 0.45, 0.50, 0.60, 0.65, 0.70, 0.80, 3mm |

| Length | 100mm to 10,000mm |

| Durability | Prone to breaking, deforming, and kinking |

| Maintenance | Clean with warm, soapy water and dry completely after each use |

Explore related products

$8.99 $9.99

What You'll Learn

Cheese wire thickness varies

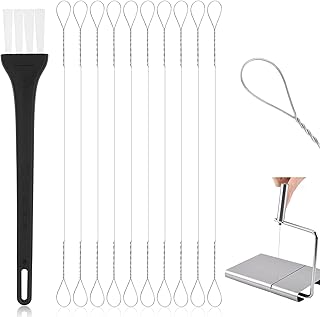

The Shark W wire, for example, offers a range of thickness options from 0.30 mm to 0.80 mm. This wire is made of stainless steel with reinforced loops at the ends, making it unique in the market. Another product, the W cheese cutter, offers wires ranging from 0.25 mm to 0.70 mm in thickness. These wires are also made of high-quality stainless steel, ensuring durability and ease of use.

The thickness of cheese wires is an important factor in achieving the desired slice thickness and maintaining the integrity of the cheese block. Thicker wires provide more strength and are better suited for harder cheeses, while thinner wires offer flexibility and precision for softer varieties. It is worth noting that proper maintenance and care, such as regular cleaning and drying, are crucial for prolonging the life of cheese wires and ensuring their effectiveness and safety.

In addition to thickness, the material of the cheese wire is also a key consideration. Stainless steel wires are commonly used due to their strength, flexibility, and corrosion resistance. They are suitable for both soft and hard cheeses and can withstand the demands of commercial kitchen environments. However, some users have reported issues with wire durability, highlighting the importance of selecting high-quality wires from reputable sources.

The Origin Story of Provolone Cheese

You may want to see also

Stainless steel is a common material

Stainless steel wires are available in various thicknesses, ranging from 0.25 mm to 0.8 mm, with some options even reaching 3 mm in thickness. The thicker wires, such as those over 3 mm, are recommended for heavy-duty applications beyond cheese cutting, such as construction supports, marine applications, and heavy industrial use. They can withstand significant weight and tension without bending or warping.

For cheese cutting, the ideal thickness of the stainless steel wire depends on the type of cheese being sliced. For semi-hard cheeses like Cheddar, Gouda, or Monterey Jack, a medium thickness wire is suitable. This thickness provides a good balance between flexibility and strength, allowing the wire to cut through denser textures without bending. For softer cheeses, a thinner wire is preferred as it can easily slice through the cheese without sticking or dragging, creating thin, clean slices.

Thicker stainless steel wires, on the other hand, are recommended for hard or aged cheeses like Parmesan, aged Pecorino, or Grana Padano. These varieties require a wire that can exert more force without bending or breaking. The "Shark W" wire, for example, is made from stainless steel and features reinforced loops at the ends, making it suitable for all types of cheese cutters and meeting the demands of even the most exacting customers.

Cheese Drug: What's in This Deadly Mix?

You may want to see also

Wires need to be flexible and strong

For semi-hard cheeses, such as Cheddar, Gouda, or Monterey Jack, a medium-thickness wire is recommended. These wires offer a good balance between flexibility and strength, allowing them to cut through denser textures without bending. A slightly thicker wire can handle the resistance of these cheese types while still producing a clean, straight slice.

For hard or aged cheeses like Parmesan, aged Pecorino, or Grana Padano, thicker wires made of stainless steel are recommended. These wires are extremely strong and can exert more force without bending or breaking. They are commonly used in construction supports, marine applications, and heavy industrial use.

To prolong the life of cheese wires and ensure their safety and efficacy, proper maintenance and care are essential. Regular cleaning with warm, soapy water and thorough drying are necessary to prevent corrosion, especially for wires made of galvanised steel. Occasional wiping with a mild disinfectant is recommended for stainless steel and coated wires to maintain hygiene and prevent residue buildup. To avoid moisture-induced damage, cheese wires should be stored in a dry environment, and coiling the wire can prevent tangling and accidental injuries.

Pule Cheese: A Unique, Expensive Serbian Delicacy

You may want to see also

Explore related products

Proper maintenance is essential

To avoid moisture-induced damage, cheese wires should always be stored in a dry environment. Coiling the wire and storing it in a dedicated space can prevent tangling and damage. It is important to ensure that the ends of the wire are not exposed to avoid accidental cuts or injuries. Regular inspections for signs of wear, fraying, or corrosion can help identify when a replacement is needed.

The ideal cheese wire combines strength, flexibility, and corrosion resistance. The strength of the wire is crucial for cutting through harder cheeses without bending or breaking. Thicker wires, typically made of stainless steel, are recommended for hard or aged cheeses like Parmesan, aged Pecorino, or Grana Padano. These thicker wires can exert more force without bending or breaking.

Additionally, the flexibility of the wire is essential for achieving a clean cut in softer cheeses without crushing their delicate structure. For semi-hard cheeses, such as Cheddar, Gouda, or Monterey Jack, a medium-thickness wire is suitable. These wires balance flexibility and strength, allowing them to cut through denser textures neatly.

Cheese Tortellini: Know the Ingredients and Their Benefits

You may want to see also

Different wires for different cheeses

When it comes to cheese wires, one size does not fit all. The ideal wire for cutting cheese needs to combine strength, flexibility, and corrosion resistance. The type of wire required is largely determined by the cheese being cut. For example, the best wire for soft cheeses like mozzarella, soft blues, and Camembert is a thin wire that can easily slice through without sticking or dragging. This type of wire will not crush the surface or smear the cut edge, which can happen when using a cheese knife.

For semi-hard cheeses, such as cheddar, gouda, or Monterey jack, a medium-thickness wire is more suitable. This type of wire offers a good balance between flexibility and strength, allowing for a neat cut without bending.

Thicker wires are required for hard or aged cheeses like Parmesan, aged Pecorino, or Grana Padano. These wires are usually made from stainless steel and are over 3mm in thickness. They can exert more force without bending or breaking, which is necessary for cutting through denser cheeses.

It is important to note that proper maintenance and care are essential to prolong the life of cheese wires. Regular cleaning with warm, soapy water and thorough drying are recommended to prevent corrosion, especially for wires made of galvanized steel. Additionally, occasional wiping with a mild disinfectant can help maintain hygiene and prevent residue buildup on stainless steel and coated wires.

Pamesean Cheese: Where is it Made and Why There?

You may want to see also

Frequently asked questions

Cheese wire is typically made from stainless steel.

The ideal thickness of a cheese wire depends on the type of cheese being cut. For soft cheeses, a thin wire is suitable, while a medium thickness is more suitable for semi-hard cheeses. For hard cheeses, a wire with high tensile strength and a thickness of over 3mm is recommended.

To prolong the life of your cheese wire, proper maintenance and care are essential. The cheese wire should be cleaned regularly with warm, soapy water and dried completely to prevent corrosion. Occasional wiping with a mild disinfectant is recommended to maintain hygiene and prevent residue buildup.

Cheese wire can be purchased from various online retailers, such as Amazon and specialty food tool stores like BOSKA and Wire-Tehnics.