Cold pack cheese, also known as club cheese or crock cheese, is a type of cheese spread that is created by blending natural cheeses without the use of heat. It was invented in Wisconsin during the Great Depression by a tavern owner who wanted to provide a snack for his customers. Cold pack cheese is made by blending two or more varieties of fresh and aged natural cheese, resulting in a soft, creamy, and spreadable texture. It is often flavoured with spices, fruits, vegetables, meats, or other flavourings, and commonly sold in crocks or plastic tubs.

Explore related products

What You'll Learn

Cold pack cheese is a soft, spreadable blend of cheeses

The name "cold pack" refers to the method of production, which does not involve heat treatment or cooking. This results in a more intense flavor that tastes like the constituent cheeses. Cold pack cheese is perishable and requires refrigeration due to the absence of heat processing. It is typically sold in crocks or plastic tubs and is a convenient product for entertaining or snacking.

The appearance of cold pack cheese is similar to natural cheese, but its soft and spreadable texture sets it apart. During the ripening process, the cheese changes from a white to an orange color, and the taste sharpens. It is available in various forms, including balls, logs, bulk tubs, and party cakes. The versatility of cold pack cheese makes it a popular choice for dips, snacks, and breakfast options.

The production of cold pack cheese is regulated by the FDA, which has set standards of identity for "cold-pack and club cheese," "cold-pack cheese food," and "cold-pack cheese food with fruits, vegetables, or meats." The absence of heat treatment in the production process allows cold pack cheese to better preserve the taste and texture of the cheeses used as a base, resulting in a spreadable product that closely resembles its natural counterparts.

Cheese Crackers: Why Are They So Expensive?

You may want to see also

It is made without heat, so it must be refrigerated

Cold pack cheese, also known as club cheese, crock cheese, or comminuted cheese, is a type of cheese spread that is created by blending two or more varieties of fresh and aged natural cheese without the use of heat. The name "cold pack" refers to the method by which it's made—without heat. Because it is made without heat, cold-pack cheese is not shelf-stable and must be refrigerated.

Cold-pack cheese was first made by a Wisconsin tavern owner during the Great Depression. It is said that tavern owners in the early 1900s, including at Milwaukee's Pabst Brewery, mixed different bits of cheese as a free snack for customers. In a nod to these origins, some still refer to cold-pack as "pub cheese." According to the Center for Dairy Research at the University of Wisconsin-Madison, cold-pack cheese began as a dip or spread made from old cheeses that were beginning to dry out.

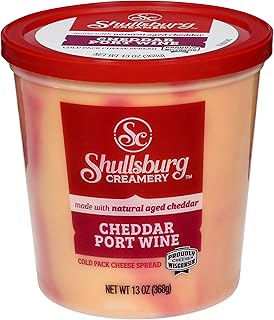

The process of making cold-pack cheese involves blending cuts of natural cheese, such as Cheddar or Swiss cheeses, with cream and other dairy ingredients until a smooth, spreadable texture is achieved. Additional ingredients such as herbs, spices, nuts, beer, wine, vegetables, or fruits are then added to create various flavours. Common flavourings include almonds, port wine, horseradish, and smoked flavour.

Unlike processed cheese spreads that are heat-treated or cooked before packaging, cold-pack cheese has a more intense flavour that tastes like the cheeses they're made from. It also has a softer, creamier texture and better preserves the taste and texture of its constituent cheeses. However, the lack of heat treatment means that cold-pack cheese must be refrigerated and has a shorter shelf life compared to heat-treated cheese spreads.

Philly Cheese Steak: Sliced Beef, Melty Cheese, and More!

You may want to see also

It was invented in Wisconsin during the Great Depression

Cold pack cheese, also known as club cheese or crock cheese, was invented in Wisconsin during the Great Depression. It is a type of cheese spread that is created by blending natural cheeses without the use of heat. The invention of cold pack cheese is often attributed to Hubert Fassbender, a Wisconsin tavern owner who ran a beer depot and had his own dairy distribution company. Fassbender started giving his customers a blend of spreadable cheese and beer, likely made from leftover cheese bits. Customers enjoyed the snack so much that they soon began requesting the cheese without the beer.

Fassbender's creation quickly gained popularity, and it became a staple in supper clubs and taverns throughout Wisconsin. The cheese was initially sold in crocks, and it is still referred to as "crock cheese" by some. In 1933, Fassbender's brand was named Kaukauna Klub cold pack cheese. The name "cold pack" refers to the method of production, which does not involve heat treatment or cooking. This results in a spread that closely resembles the taste and texture of its constituent natural cheeses.

The original cold pack cheese was likely made from a blend of different cheeses, creating a unique and flavourful spread. Over time, other cheese manufacturers began developing their own versions of cold pack cheese, incorporating various ingredients and flavour profiles. Today, cold pack cheese is often made using Cheddar or Swiss cheeses as a base, with added spices, fruits, vegetables, or nuts for flavouring. Common flavourings include almonds, port wine, horseradish, and smoked flavours.

The absence of heat treatment in the production process means that cold-pack cheese is not shelf-stable and requires refrigeration. Despite this, it has become a beloved and iconic food product in Wisconsin and beyond. It is often enjoyed as a snack or appetizer, spread on crackers or used as a dip, and has become a holiday tradition in many households.

Great Value Cheese: Where Is It Made?

You may want to see also

Explore related products

It is often made using Cheddar or Swiss cheese as a base

Cold pack cheese is a type of cheese spread that is created by blending two or more varieties of natural cheeses without the use of heat. It was first made by a Wisconsin tavern owner during the Great Depression. The cheese is often made using Cheddar or Swiss cheese as a base, with added spices, fruits, vegetables, or nuts as flavouring. Common flavourings include almonds, port wine, horseradish, and smoked flavour.

Being made from natural cheese without heat, cold-pack cheese has a soft, creamy, and spreadable texture that better preserves the taste and texture of its constituent cheeses. It is not shelf-stable and requires refrigeration. The FDA has standards of identity for the production of "cold-pack and club cheese", "cold-pack cheese food", and "cold-pack cheese food with fruits, vegetables, or meats".

Cheddar cold pack cheese is a popular variety, with some manufacturers blending it with ingredients like jalapeño, onions, salsa, or tomato. Other popular flavour combinations include garlic and herb, chocolate, and mango salsa.

Cold pack cheese is also known as club cheese, crock cheese, or comminuted cheese. It is traditionally sold in crocks but is now available in plastic tubs, balls, logs, bulk tubs, and party cakes.

Cheese-Making Process: My Cafe's Secret Recipes

You may want to see also

Common flavourings include almonds, port wine, horseradish and smoked flavour

Cold pack cheese, also known as club cheese or crock cheese, is a type of cheese spread that is created by blending natural cheeses without the use of heat. Common flavourings include almonds, port wine, horseradish and smoked flavour.

The name 'cold pack' refers to the method by which it's made, without the use of heat. Because it is not heat-processed, cold-pack cheese is not shelf-stable and requires refrigeration.

Cold-pack cheese was first made by a Wisconsin tavern owner during the Great Depression. It is said that tavern owners in the early 1900s, including at Milwaukee's Pabst Brewery, mixed bits of different cheeses as a snack for customers. In a nod to these origins, some still refer to cold-pack cheese as 'pub cheese'.

The cheese is often flavoured with spices, fruits, vegetables, meats, herbs, and nuts. Some popular flavour combinations include almonds, port wine, horseradish, and smoked flavour. Cold-pack cheese with almonds is a popular choice, as the nuts add a crunchy texture and a nutty flavour to the cheese. Port wine cold-pack cheese is also a favourite, with its rich, sweet, and slightly tangy flavour. Horseradish cold-pack cheese offers a sharp and pungent kick, while smoked-flavoured cold-pack cheese adds a subtle, smoky taste. These flavourings are often added to a base of cheddar or Swiss cheese, resulting in numerous combinations.

Cheddar Cheese: Which Animal Milk Is Used?

You may want to see also

Frequently asked questions

Cold pack cheese is made by blending two or more varieties of fresh and aged natural cheese without the use of heat.

Cold pack cheese has a more intense flavour that tastes like the cheeses they're made from.

Cold pack cheese is often made using Cheddar or Swiss cheeses as a base, with added spices, fruits, vegetables, or nuts as flavouring.