Mold is an essential component of the cheesemaking process, serving two main purposes: the first is to act as a culture that transforms the fats and proteins in milk into cheese, and the second is to give each variety of cheese its distinct appearance, taste, and texture.

| Characteristics | Values |

|---|---|

| Purpose | Adds texture and flavour to the cheese |

| Protects and preserves cheese | |

| Types | Natural and spoiled |

| Natural mold examples | Penicillium roqueforti, Penicillium candidum, Geotrichum candidum |

| Spoiled mold characteristics | Fuzzy green, black, blue, white, or grey colour |

| Spoiled mold effects | Changes appearance, smell, and taste of cheese |

Explore related products

What You'll Learn

- The addition of moulds gives cheese its distinct flavour and texture

- Different moulds are used for different types of cheese

- Some moulds are applied externally, while others are added internally

- Moulds are used to form a rind that protects the cheese

- Moulds are essential for the ripening process of cheese

The addition of moulds gives cheese its distinct flavour and texture

There are two types of mould-ripened cheeses: internally ripened and externally ripened. Blue cheese is an example of an internally ripened cheese, where mould grows inside the cheese. Penicillium roqueforti is added to the milk during cheesemaking, and the cheese is pierced with a needle to let oxygen in, allowing the mould to grow throughout the interior. Externally ripened cheeses, on the other hand, develop mould on their exterior. Brie and Camembert are examples of these, where Penicillium candidum forms a white bloomy rind during the aging process.

The type of mould added to cheese affects both its flavour and texture. For example, the PRB6 strain of Penicillium Roqueforti, used in blue cheese, gives a strong blue flavour. The addition of mould can also create a rind, protecting and mellowing the cheese. The mould on Brie, for instance, forms a savoury, mushroomy rind that contributes to its distinct flavour and texture.

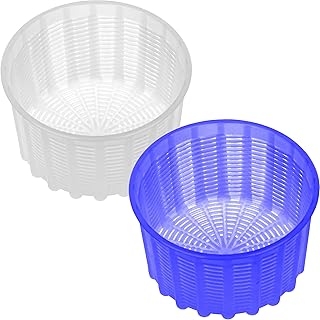

The size, shape, and drainage of the mould used during the cheese-making process will also impact the final product. The height-to-width ratio and surface-to-mass ratio affect ripening, stability, and even distribution of flavours and textures.

While mould is essential for creating flavour and texture in certain cheeses, it can also negatively impact these characteristics if it is not the desired type of mould. Unwanted mould growth can alter the appearance, smell, and taste of the cheese. Therefore, cheesemakers must carefully manage the growth of mould, ensuring the right kind of mould is growing in the right place at the right time.

Cheese Manicotti: The Perfect Pairing Guide

You may want to see also

Different moulds are used for different types of cheese

There are two types of mould: natural and spoiled. The spoiled kind is the one that usually appears as fuzzy green, black, blue, white, or grey and suggests spoilage as it changes the appearance, smell and taste of food. On the other hand, the natural kind is required to make particular kinds of cheeses. Cheese moulds are essential in the cheese-making process as they give cheese its unique flavour and texture.

Moulds are also used to make soft-ripened cheeses like brie and camembert. The white mould on the outside of these cheeses aids in the ripening process, adding subtle flavours. The mould also serves as a rind to protect and mellow the cheese. A classic white mould powder is used to ripen and flavour the cheese, achieving a moderate-slow ripening time.

For those with dietary restrictions, there are vegan and dairy-free options available for making cheese at home. A vegan, liquid form of mould can be applied directly to the medium to make vegan blue cheese. This mould is sprayed on after being diluted with water.

Cheese moulds come in different materials, such as stainless steel and polypropylene, each serving its own purpose. For instance, stainless steel moulds are used to make Camembert, while polypropylene moulds are used for a variety of cheeses.

Camembert Charcuterie: Serving the Perfect Cheesy Delight

You may want to see also

Some moulds are applied externally, while others are added internally

The role of mould in cheesemaking is complex and multifaceted. While some moulds are applied externally to form a crust or rind, others are added internally to create specific textures, flavours, and colours.

Externally applied moulds are a common practice in cheesemaking, where they form a protective rind that contributes to the cheese's overall character. This rind not only safeguards the cheese but also enhances its flavour and texture. One notable example is the white mould (Penicillium candidum) found on Brie and Camembert, which lends a mellow, savoury, and mushroomy taste to these cheeses. This type of mould is intentionally cultivated and carefully managed by cheesemakers to achieve the desired sensory attributes.

In contrast, internally ripened cheeses involve the addition of moulds during the cheesemaking process. Blue cheeses, with their distinctive colourful veins, exemplify this technique. Penicillium roqueforti, a type of mould, is added to the milk, and the introduction of oxygen through piercing encourages mould growth throughout the interior of the cheese. This internal moulding process results in the unique flavour and texture profiles associated with blue cheeses.

The application of moulds in cheesemaking is a delicate balance. While the right moulds can transform milk's fats and proteins into flavourful compounds, undesirable moulds can negatively impact the cheese's flavour and texture. Cheesemakers must carefully manage this process, ensuring the growth of the intended moulds while preventing the proliferation of unwanted moulds.

The art of cheesemaking relies on the precise utilisation of moulds, whether applied externally or internally. Each type of mould introduces distinct characteristics, contributing to the vast array of cheeses available today.

Cheese It Servings: How Many in a Box?

You may want to see also

Explore related products

Moulds are used to form a rind that protects the cheese

Mould plays a crucial role in the cheesemaking process, and one of its primary purposes is to form a protective rind around the cheese. This rind not only safeguards the cheese but also contributes to its unique texture and flavour.

The process of using moulds to create a rind involves carefully cultivating specific mould strains on the cheese's surface. One of the most well-known examples is the white rind of Brie and Camembert, formed by the Penicillium candidum mould strain. This mould strain is intentionally applied or allowed to grow naturally, creating a distinctive "bloomy rind." During the ageing process, cheesemakers pat down the mould, encouraging the growth of a smooth, snowy coating. This mould forms a protective barrier, shielding the cheese from external contaminants and helping to regulate moisture levels.

The mould rind also plays a crucial role in developing the cheese's flavour and texture. As the mould grows, it releases enzymes that break down the cheese's curds, facilitating the ripening process. This breakdown of curds results in the creamy texture characteristic of Brie and Camembert. Additionally, the mould contributes to the cheese's flavour profile, imparting savoury and buttery notes often described as mushroomy.

Different mould strains can be used to create a variety of rind colours and flavours. For instance, the Neige strain, used in Camembert and Brie, produces a bright white appearance and a rapid breakdown of curds. Other natural rinds may exhibit a range of colours, including brown, yellow, red, orange, grey, and blue, depending on the mould strains and bacteria present. These naturally occurring rinds result in strong flavours and aromas influenced by the cheese cave environment.

The use of mould to form a protective rind is a delicate process that requires careful monitoring. Cheesemakers must ensure that the desired mould strain dominates, intervening if necessary to prevent the growth of undesirable moulds. This practice, known as "mould maintenance," ensures that the right type of mould thrives in the right place at the right time. Overall, the use of mould to form a rind in cheesemaking is a complex and nuanced process that significantly impacts the final product's quality, flavour, and texture.

Creating the Perfect Cheese Board

You may want to see also

Moulds are essential for the ripening process of cheese

Mould is an essential component of cheesemaking and plays a vital role in the ripening process. It gives cheese its distinctive texture and flavour, and in the case of soft cheeses, it acts as a rind to protect the cheese.

There are two types of mould-ripened cheeses: internally ripened and externally ripened. Internally ripened cheeses, such as blue cheese, have mould growing inside the cheese, while externally ripened cheeses, like Brie and Camembert, develop mould on their exterior, forming a white bloomy rind.

The mould used in cheesemaking is typically added as a fungal starter culture. For blue-veined cheeses, Penicillium roqueforti is added to the milk, and oxygen is introduced by piercing the cheese to allow the mould to grow throughout the interior. Externally ripened cheeses are inoculated with Penicillium candidum, which forms the signature white mould.

The choice of mould strain is crucial, as it determines the cheese's texture, flavour, and ripening time. For example, the Neige strain provides rapid growth and curd breakdown, while also supporting a slow maturation process, making it ideal for Camembert or Brie.

In addition to moulds, other microorganisms like bacteria and yeasts also play a role in the ripening process. These cultures help coagulate the milk into curd and release enzymes during ageing, contributing to the development of flavour and texture. The presence of these microorganisms is what largely defines cheese, giving it its unique characteristics.

Savory Slider Sides: Perfect Partners for Ham & Cheese

You may want to see also

Frequently asked questions

The two main purposes of mould in cheesemaking are to 1) act as a culture to transform the fats and proteins in milk into cheese, and 2) to create a rind to protect and mellow the cheese.

Natural or healthy mould is used during the production process of certain cheeses. Spoiled mould, on the other hand, usually indicates that food has gone bad. It changes the appearance, smell, and taste of the food.

There are two types of mould-ripened cheeses: internally ripened and externally ripened. Blue cheese is an example of an internally ripened cheese, as it has veins of mould running through it. Brie, Camembert, Trillium, and Little Lucy Brie are examples of externally ripened cheeses, as they develop a mouldy rind during the aging process.

Some common types of mould used in cheesemaking include Penicillium roqueforti, P. glaucum, and P. candidum.