Happy Farms cheese is available at ALDI in the US. The range includes mozzarella string cheese, which is marketed as a snack for both kids and adults.

| Characteristics | Values |

|---|---|

| Manufacturer | Aldi |

| Availability | US |

Explore related products

What You'll Learn

Happy Farms cheese is available at Aldi

Happy Farms cheese is also available at Costco, where it is sold under the Kirkland brand name. It is unclear whether the cheese is made in the same factory or if it is simply repackaged and rebranded for different supermarkets.

Happy Farms cheese is likely made in the United States, as it is sold at American supermarkets and the Eat Well Guide helps consumers find locally grown and sustainably produced food. However, it is worth noting that California and Arizona are excluded from some meat and seafood promotions at Aldi, so it is possible that Happy Farms cheese is not available in those states.

Yak Mozzarella: A Cheesy Adventure in the Himalayas

You may want to see also

It is made in the same place as Kirkland cheese

Happy Farms cheese is made in the same place as Kirkland cheese. The cheese is available to buy at ALDI, where you can also find a range of other Happy Farms dairy products, including mozzarella string cheese. Happy Farms cheese is a good source of calcium and has only 70 calories per serving.

The History of Boar's Head Cheese and Its Origins

You may want to see also

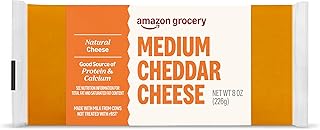

It is available in mozzarella and cheddar varieties

Happy Farms cheese is available in mozzarella and cheddar varieties. You can buy mozzarella string cheese, which is a great snack for kids and adults, as it's a good source of calcium and has only 70 calories per serving. You can also buy medium cheddar deli-sliced cheese. Happy Farms cheese is available at ALDI in the US, in California and Arizona.

The Cheeseburger's Historical Debut: When Cheese Met Patty

You may want to see also

Explore related products

$1.84

$1.74

It is available in string form

Happy Farms cheese is available in string form and can be purchased at ALDI. It is made from mozzarella and is marketed as a snack for both kids and adults. It is a good source of calcium and has only 70 calories per serving. It is also available at Costco.

Cheese Whiz: Unveiling the Four-Letter Word Mystery

You may want to see also

It is available in California and Arizona

Happy Farms cheese is available at Aldi in California and Arizona. It is unclear where the cheese is made, but it is sold at Aldi stores in the US.

Violife Cheese: What's It Made Of?

You may want to see also

Frequently asked questions

Yes, Happy Farms cheese is sold at Aldi.

Aldi carries a majority of private-label goods, so the origins of their products are often unknown. However, I can tell you that some of their cheese is made in Germany and Canada. Some of their cheese is also made in Scotland, at Langdale Farm in Ayrshire.

Happy Farms makes mozzarella string cheese.

You can buy Happy Farms cheese at Aldi.