Parmesan cheese, or Parmigiano-Reggiano, is a hard, granular Italian cheese made from raw cow's milk and aged for at least 12 months. It is produced in several provinces in northern Italy, including Parma, Reggio Emilia, Modena, and Bologna. Parmesan is a popular cheese variety, often used as a topping for pasta, salads, and pizza. However, the term Parmesan has different definitions outside of Europe, with various manufacturers producing their versions of Parmesan-style cheese.

Explore related products

What You'll Learn

Parmesan cheese is made in specific Italian provinces

Parmesan cheese, or Parmigiano-Reggiano, is made in specific Italian provinces and is a protected designation of origin (PDO) product. This means that, by law, the term Parmesan may only be used to refer to Parmigiano-Reggiano when it is made in these restricted geographic areas and using strictly defined methods. The provinces where Parmigiano-Reggiano is produced include Parma, Reggio Emilia, Modena, parts of Bologna west of the River Reno, and parts of Mantua on the south bank of the River Po. The names Parmigiano and Reggiano come from the Italian adjectives for the city and province of Parma and the province of Reggio Emilia, respectively.

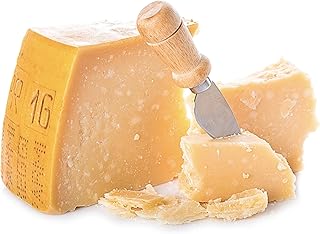

Parmigiano-Reggiano is a hard, granular cheese produced from raw cow's milk and aged for at least 12 months. It is a type of extra-hard Italian cheese that is usually grated and paired with typical Italian pasta dishes, such as spaghetti. However, it can also be eaten in slivers and is a part of Italian national cuisine. The original Parmesan cheese, Parmigiano-Reggiano, is one of the most expensive cheeses in the world.

Outside of Europe, the name "Parmesan" has become genericized, and it may refer to any number of hard Italian-style grating cheeses. These imitation Parmesan cheeses are often produced in the United States and Argentina and are commercialized under names that evoke the original, such as Parmesan, Parmigiana, Parmesana, Parmabon, and Real Parma. In the United States, the Code of Federal Regulations includes a Standard of Identity for "Parmesan and Reggiano cheese", which defines aspects of both the production process and the final result.

Within the European Union, the protection of the Parmigiano-Reggiano name is strictly enforced, and special seals are used to identify authentic products. These seals include the identification number of the dairy, the production month and year, a code identifying the individual wheel, and stamps regarding the length of aging. The strict regulation of Parmigiano-Reggiano helps to ensure that this traditional Italian cheese is made and sold according to its protected designation of origin.

Swaledale Cheese: A Taste of the Yorkshire Dales

You may want to see also

It's made from raw cow's milk

Parmesan cheese, or Parmigiano-Reggiano, is made from raw cow's milk. It is a hard, granular Italian cheese that is usually grated and used in pasta dishes, although it can also be eaten in slivers. It is produced in the provinces of Parma, Reggio Emilia, Modena, Mantua (partly), and Bologna (partly). The name Parmigiano-Reggiano is derived from two of the areas that produce it: the Italian provinces of Parma and Reggio Emilia. The name Parmigiano is the Italian adjective for the city and province of Parma, while Reggiano is the adjective for the province of Reggio Emilia.

Parmigiano-Reggiano is a protected designation of origin (PDO) under Italian and European law, meaning that the way it is made and the region in which it is produced are strictly controlled. The brand Parmigiano Reggiano is also protected in Europe. As a result, within the European Union, the term "Parmesan" may only be used by law to refer to Parmigiano-Reggiano itself, which must be made using stringently defined methods in a restricted geographic area.

Outside of Europe, the term Parmesan has become genericized, and it may be used to refer to any of several hard Italian-style grating cheeses. These imitation Parmesan cheeses are produced in various regions, including the US and Argentina, and are often commercialized under names intended to evoke the original, such as Parmesan, Parmigiana, Parmesana, Parmabon, Real Parma, Parmezan, or Parmezano. In the United States, the Code of Federal Regulations includes a Standard of Identity for "Parmesan and Reggiano cheese," which defines both the production process and the final result.

To be considered Parmesan, the cheese must be made from cow's milk, cured for at least 10 months, and contain no more than 32% water and no less than 32% milkfat in its solids. The cows producing the milk may be fed silage or grass, and the milk may contain slightly less fat. The milk from several different days may be used, but it must be aged for at least 9-12 months.

Athenos Feta Cheese: Crafted From Traditional Greek Recipes

You may want to see also

The name Parmesan is protected in Europe

Parmesan cheese, or Parmigiano Reggiano, is an Italian hard, granular cheese made from raw cow's milk and aged for at least 12 months. It is produced in the provinces of Parma, Reggio Emilia, Modena, Mantua, and Bologna. The name Parmesan is protected in Europe, specifically within the European Union, where it may only be used by law to refer to Parmigiano Reggiano itself. This means that the term Parmesan can only be used for cheese produced in a restricted geographic area using strictly defined methods.

The Consortium of Parmigiano Reggiano Cheese, a group of Italian cheese makers, brought the case to the European Court, noting that Parmigiano Reggiano has been registered as a protected designation of origin (PDO) in the European Union since 1996. In 2008, the EU court ruled that the name Parmesan in Europe exclusively refers to Parmigiano Reggiano and cannot be used for imitation Parmesan. This ruling means that Parmigiano Reggiano is a PDO-protected product, and the name refers only to the cheese manufactured in a limited area in northern Italy.

Outside of the EU, the name Parmesan is legally used for imitations, and only the full Italian name, Parmigiano Reggiano, refers to the PDO-protected cheese. In many areas outside of Europe, the name Parmesan has become genericized, and it may refer to any hard Italian-style grating cheese. These cheeses, mainly from the US and Argentina, are often marketed with names that evoke the original, such as Parmesan, Parmigiana, Parmesana, and Parmezano.

The protection of the Parmesan name in Europe is part of a broader effort by the EU to restrict the use of certain European cheese names for products made outside of Europe. The EU argues that American-made cheeses are inferior imitations that negatively impact the sales and identity of the original European varieties. However, this move has faced opposition from some non-European cheese producers, who claim that it is more about controlling trade than ensuring quality.

Cheese Cultures: What's Inside Your Favorite Dairy Product?

You may want to see also

Explore related products

It's a hard, granular cheese

Parmesan cheese is a hard, granular cheese produced from cow's milk. It is generally pale yellow in colour and is usually grated over dishes such as pasta, Caesar salad, and pizza. The original Parmesan cheese, also known as Parmigiano-Reggiano, is produced only in Italy, specifically in the provinces of Parma, Reggio Emilia, Modena, Mantua (partly), and Bologna (partly).

Parmigiano-Reggiano is a protected designation of origin (PDO) cheese, which means that it can only be manufactured in a restricted geographic area using strictly defined methods. The name "Parmesan" has become genericised in many areas outside of Europe, and may refer to any number of hard Italian-style grating cheeses. These imitation Parmesan cheeses are often produced in the US and Argentina and are commercialised under names such as "Parmigiano", "Parmigiana", and "Parmabon".

Within the European Union, the term "Parmesan" by law, refers exclusively to Parmigiano-Reggiano and cannot be used for imitation Parmesan. The protection of the Parmigiano-Reggiano name has led to the regulation of the product, with special seals identifying the product as authentic, including the identification number of the dairy, the production month and year, and a code identifying the individual wheel.

In the United States, the Code of Federal Regulations includes a Standard of Identity for "Parmesan and Reggiano cheese", which defines both the production process and the final result. This includes specifications such as the requirement to be made from cow's milk, cured for at least 10 months, and contain no more than 32% water and no less than 32% milk fat. Several American manufacturers have been investigated for allegedly exceeding the 4% cellulose limit allowed in grated Parmesan cheese.

The Art of Cotija Cheese Making

You may want to see also

It's usually grated on pasta dishes

Parmesan cheese, or Parmigiano-Reggiano, is a hard, granular Italian cheese produced from cow's milk. It is aged for at least 12 months and is known for its sharp, nutty flavour. The cheese is named after two of the areas which produce it: the Italian provinces of Parma and Reggio Emilia. It is also produced in part of Bologna, Modena, and Mantua. Parmesan cheese is a protected designation of origin (PDO) product, which means that under Italian and European law, the names Parmigiano Reggiano and Parmesan can only refer to the specific cheese manufactured in these provinces.

Parmesan cheese is a popular topping for pasta dishes, such as spaghetti, and is often grated onto these dishes before serving. Its sharp, salty flavour and granular texture make it an ideal cheese to complement a variety of pasta sauces and preparations. While it is typically grated, it can also be sliced into slivers and added to pasta or other dishes.

The popularity of Parmesan cheese has led to its widespread imitation, and it has become an increasingly regulated product. Within the European Union, the term 'Parmesan' may only be used to refer to Parmigiano-Reggiano itself, and it must be made using specific methods in a restricted geographic area. Outside of Europe, the name 'Parmesan' has become genericised, and it may refer to any number of hard Italian-style grating cheeses. These imitation cheeses are often commercialised under names that evoke the original, such as Parmesan, Parmigiana, Parmesana, or Parmezano.

In the United States, the Code of Federal Regulations includes a Standard of Identity for "Parmesan and Reggiano cheese", which defines the production process and the final result. American manufacturers have been investigated for allegedly exceeding the 4% cellulose limit allowed in grated cheese. In one case, a Pennsylvania manufacturer was found to be selling a mixture of cheeses and cellulose with no actual Parmesan content.

Cheese Without Rennet: Exploring Rennet-Free Cheesemaking

You may want to see also

Frequently asked questions

Parmesan cheese, or Parmigiano-Reggiano, is made in the Italian provinces of Parma, Reggio Emilia, Modena, Mantua (partly) and Bologna (partly).

Yes, outside of Europe, imitation Parmesan cheese is made in the US, Canada, and Argentina.

Parmesan cheese is made from raw cow's milk.

Parmesan cheese is typically aged for at least 12 months, though some American varieties are aged for less than 12 months.

Within the European Union, the term Parmesan may only be used to refer to Parmigiano-Reggiano, which is made in a restricted geographic area using specific methods. Outside of Europe, the term Parmesan has become genericised and is used to refer to a variety of hard Italian-style grating cheeses.