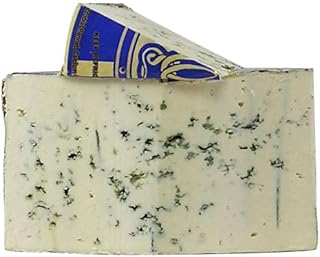

Blue cheese is a common type of cheese known for its distinct flavour, smell, and appearance. It is made using Penicillium, a type of mold that creates blue-green spots or veins throughout the cheese. Blue cheese can be made from various animal milks, including cow, goat, sheep, or even buffalo milk, and the cheesemaking process requires careful control of temperature and humidity. During the aging process, the cheese is punctured to allow air to penetrate and support the growth of Penicillium cultures, forming the characteristic blue veins. While blue cheese is safe to consume due to the use of non-toxic Penicillium strains, improper storage can cause it to spoil, leading to food safety concerns.

Explore related products

$17.97

What You'll Learn

Blue cheese is made using Penicillium, a type of mold

Blue cheese is made using Penicillium, a type of mould that is responsible for its unique taste, smell, and appearance. Unlike other types of mould, Penicillium does not produce toxins and is safe to consume. The mould is added during the initial cheesemaking process, and the blue veins that characterise blue cheese are created by piercing the cheese with needles or spikes to allow oxygen to circulate and the mould to flourish. This piercing method is the main way of making blue cheese, although some varieties are made by directly injecting the mould into the cheese.

During the ripening process, the temperature and humidity of the room are carefully monitored to ensure the cheese does not spoil and develops its optimal flavour and texture. The cheese is ripened at a temperature of around 8 to 10 degrees Celsius with a relative humidity of 85-95%. At the beginning of this process, the cheese loaves are punctured to create small openings for air to penetrate and support the growth of aerobic Penicillium cultures, thus encouraging the formation of blue veins. The total ketone content is also constantly monitored as the distinctive flavour and aroma of blue cheese are the result of methyl ketones, which are a metabolic product of Penicillium.

After about four weeks, the cheese is covered in a full mouldy fur, and this mould is wiped or scraped off to prevent it from overtaking the entire block of cheese. The blue cheese ripening process takes about 2.5 to 6 months. It is important to store blue cheese properly, as it can still go bad, and it should be tightly wrapped and refrigerated, where it can last for 3-4 weeks. Frozen blue cheese can last indefinitely, although its texture and appearance may be slightly altered.

Blue Cheese Chips: Who Serves This Unique Dish?

You may want to see also

The mold is added during the initial cheesemaking process

Blue cheese is made by adding mould to the cheese during the initial cheesemaking process. This mould is from one or more strains from the genus Penicillium, specifically Penicillium roqueforti, which is responsible for the unique taste, smell, and appearance of blue cheese. Unlike other types of mould, Penicillium does not produce toxins and is safe to consume.

During the cheesemaking process, the mould is added after the curds have been drained and rolled into wheels. The cheese is then punctured to create small openings, allowing air to penetrate and supporting the growth of aerobic Penicillium roqueforti cultures, which encourages the formation of blue veins. This process is called "needling" and it is done in a controlled environment with a temperature of around 8 to 10 degrees Celsius and a relative humidity of 85-95%.

The entire blue cheese ripening process takes about 2.5 months. After about 4 weeks, the blue cheese will be covered in a full mouldy fur, and it is important to wipe or scrape off the excess mould to prevent it from overtaking the entire block of cheese. After sufficient blue mould growth, the cheeses are wrapped tightly in foil and refrigerated for up to 4-6 months.

The piercing method of adding mould to blue cheese is the main method of making blue cheese, although some cheeses are directly injected with mould spores before the curds form, or have spores mixed in with the curds after they form.

The Intriguing World of Blue-Veined Cheese

You may want to see also

The cheese is punctured to create openings for air to penetrate

Blue cheese is made using Penicillium, a type of mould that is responsible for its unique taste, smell, and appearance. The mould is added during the initial cheesemaking process, but the classic veins in blue cheese are created by piercing the cheese to allow oxygen to circulate and the mould to flourish. This process is called "needling" and it involves puncturing the cheese loaves to create small openings for air to penetrate and support the growth of aerobic Penicillium roqueforti cultures, which give rise to the blue veins.

During the "needling" process, the cheese loaves are punctured with small openings to allow air to circulate within the cheese. This process is crucial for the development of the distinct blue veins in blue cheese. The openings provide oxygen, which supports the growth of the Penicillium mould cultures. This mould is safe for human consumption and does not produce toxins, making blue cheese a unique and flavourful delicacy.

The "needling" technique is an intentional and controlled step in the cheesemaking process. It is a modern approach to creating blue cheese, as opposed to the folklore belief that it began as a mistake. The piercing method allows for the even distribution of oxygen and mould throughout the cheese, resulting in the characteristic blue veins. This technique requires precision and knowledge of the cheesemaking process.

After the "needling" process, the blue cheese is typically aged in a controlled environment with specific temperature and humidity levels. This ageing period allows the mould to develop and mature, enhancing the flavour and texture of the cheese. The temperature is maintained around eight to ten degrees Celsius, and the relative humidity is kept between 85-95%. These conditions may vary slightly depending on the type of blue cheese being produced.

Overall, the puncturing of the cheese loaves to create openings for air penetration is a crucial step in the creation of blue cheese. This process, known as "needling," encourages the growth of the Penicillium mould and results in the distinct blue veins associated with this type of cheese. The controlled piercing method ensures that the mould flourishes and gives blue cheese its unique characteristics.

Who is Behind Blue Heron Cheese?

You may want to see also

Explore related products

Blue cheese is ripened in temperature-controlled environments

The process of ripening blue cheese is a delicate one, requiring constant attention to ensure the cheese does not spoil. The total ketone content, for example, is constantly monitored as the distinctive flavour and aroma of blue cheese are a result of methyl ketones, which are a metabolic product of Penicillium roqueforti. Additionally, the cheese loaves are punctured at the beginning of the ripening process to create small openings that allow air to penetrate and support the growth of aerobic Penicillium roqueforti cultures, thus encouraging the formation of the blue veins characteristic of blue cheese.

The mould used in blue cheese is from one or more strains of the genus Penicillium. This type of mould is safe for human consumption and does not produce toxins, unlike other types of mould that grow on food due to spoilage. The addition of salt to blue cheese, either during the curing process or as a preservative, is also allowed, provided it does not exceed 200 parts per million of milk and milk products used.

The ripening process for blue cheese typically takes around 2.5 months, and the cheese is often flipped daily to ensure even ripening. After this period, the cheese is wrapped tightly and refrigerated for up to 4-6 months, allowing it to develop its distinctive flavour and texture.

Blue Cheese: A Delicious, Natural Fermentation Product

You may want to see also

Blue cheese can be made from cow, goat, sheep, or buffalo milk

Blue cheese is made by adding cultures of edible moulds to regular cheese, which create blue-green spots or veins throughout. Blue cheese can vary in flavour, colour, and consistency. Some varieties are made by injecting spores into the cheese before the curds form, while others have spores mixed in with the curds after they form. Blue cheese is typically aged in temperature-controlled environments.

Blue cheese can be made from the milk of different animals, including cows, goats, sheep, and buffalo. Each type of milk produces a different kind of cheese. Cows produce the most milk of any animal—about 12 to 20 gallons a day—but because cow's milk contains a lot of water, the yield of cheese is lower than that of other animals. The flavour of cow's milk cheese is often grassy and sweet. Goat's milk, on the other hand, has a distinct flavour that is reflected in the resulting cheese. Sheep's milk is yellow and creamy, with a slight shimmer due to its high protein and fat content. This results in cheeses that are slightly oily and golden in colour, with nutty and grassy flavours. Buffalo milk has a sweet, floral, and aromatic flavour, often described as having the cleanest "milky" taste among different types of milk.

Cheese Turning Blue: Why and When It Happens

You may want to see also

Frequently asked questions

The ingredients in the soy milk or yoghurt may have changed.

Blue cheese is made using Penicillium, a type of mould that’s responsible for its unique taste, smell, and appearance.

Blue cheese can go bad if it’s not stored properly. It is important to store blue cheese tightly wrapped in the refrigerator. If stored properly, blue cheese can last 3–4 weeks in the refrigerator.

The main structure of the blue cheese comes from the aggregation of the casein.