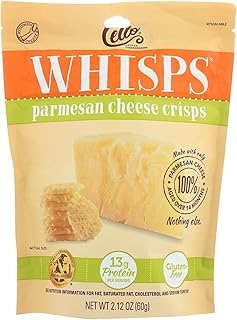

Cheese Whisps are a popular snack in the USA, made by baking cheese into a crunchy crisp. The concept is simple: grated cheese is baked in an oven until it becomes a crisp. The challenge, however, is in the execution: getting the right cheese, the right temperature, and the right duration of baking to create a consistent product that doesn't get oily, hard, or chewy.

| Characteristics | Values |

|---|---|

| Main Ingredient | Cheese |

| Cheese Varieties | Parmesan, Cheddar, Asiago |

| Production Method | Baking, Grating, Tumble Drying |

| Oven Temperature | 350°F |

| Baking Time | 10 minutes |

| Shelf Life | 1 year |

| Storage | No refrigeration required |

| Dietary Information | Gluten-free, Keto-friendly, Not vegan |

Explore related products

What You'll Learn

Grated Parmesan cheese is baked in the oven

The key to getting the right texture and taste is experimenting with different cheese weights, cooking times, and oven temperatures. When baked, the cheese melts and forms a crisp that can be seasoned with various flavours. The cooking time may vary depending on the desired level of toastiness, with longer cooking times resulting in a darker and crispier Whisp.

It is important to note that the shelf life of homemade Whisps is relatively short, as they tend to get oily, hard, or chewy within 10 to 20 minutes. However, with the right ingredients and techniques, it is possible to create a delicious and addictive snack that can be enjoyed anywhere.

Whisps were created by Schuman Cheese, the largest importer of Italian cheeses in the USA. The company initially launched Whisps as an additional item for their cheese sales team to sell alongside grated cheese and wedges. The product quickly gained popularity, and it is now available in retailers across the country, including in 65,000 stores.

Cheese Snacks: Real Deal or Cheesy Deceit?

You may want to see also

Cheese is melted in a microwave

Cheese whisps are made by baking cheese in the oven or melting it in the microwave. The cheese is grated or shredded and then baked or melted to create a crunchy texture.

To melt cheese in a microwave to make cheese whisps, you will need a silicone cupcake or muffin tray, or a silicone baking mat. You can also use paper muffin cups, but the cheese may stick to them. First, grate or shred your cheese of choice. Parmesan is a popular option, but other types of cheese, such as cheddar, can also be used. Aim for about 0.2 ounces of cheese per whisp, or adjust to your preference.

Place the cheese in the silicone mold or on the silicone baking mat, filling each slot about halfway. If using a silicone baking mat, form the cheese into small piles, leaving space between them as the cheese will spread when melted. Place the cheese in the microwave and heat for around 35-40 seconds. Check the cheese after 20 seconds; it should have started to melt by this point. If not, continue heating in 5-second intervals until it has.

Once the cheese has melted, remove it from the microwave and let it cool completely before removing it from the tins or mold. The cheese whisps are now ready to be enjoyed!

The Evolution of Chuck E. Cheese: A Historical Overview

You may want to see also

Cheese Whisps are not vegan

The process of making Cheese Whisps involves baking premium, artisanal cheese into an airy, crunchy crisp. The cheese is sourced from local farms in Wisconsin, which is known as the cheese capital of America. The milk used in the production of the cheese is rBST-free, and the farms are said to responsibly source their milk from cows that are never treated with growth hormones.

Cheese Whisps are available in a variety of flavors, including Parmesan, Cheddar, and Asiago Pepperjack. Some flavors, such as Tangy Ranch, Hot & Spicy, Nacho, and Italian Herb, contain buttermilk and therefore have lactose content.

Due to the nature of the product, Cheese Whisps are not suitable for vegan diets. However, they are gluten-free and keto-friendly, making them suitable for other dietary restrictions. The company behind Cheese Whisps, Schuman Cheese, has positioned the product as a healthy snack made with minimally processed ingredients.

While Cheese Whisps are not vegan, they have gained popularity as a snack option and are now available in 65,000 stores across the United States. The success of Cheese Whisps can be attributed to their unique texture and taste, as well as the company's effective marketing and distribution strategies.

Moon's Cheesy Mystery: What if Moon is Made of Cheese?

You may want to see also

Explore related products

Cheese Whisps are keto-friendly

Cheese Whisps are a popular snack that has taken off in recent years. They are made by baking or microwaving grated cheese into a crunchy crisp. The process is simple, but the company has perfected it to create a consistent, airy texture and taste.

The keto diet, short for the ketogenic diet, is a low-carb, high-fat diet that has become increasingly popular. Cheese Whisps are a good fit for this diet because they are low in carbohydrates and high in fat. The crisps are also gluten-free and nut-free, making them accessible to those with common dietary restrictions.

In addition to being keto-friendly, Cheese Whisps are also a healthy snack option. They are made with minimally processed ingredients and are free from added sugars. The company behind Cheese Whisps, Schuman Cheese, positions itself as a "healthy snack" brand rather than a "diet brand." This strategy has helped them grow their customer base and differentiate themselves from other snack options.

Cheese Whisps have a long shelf life of one year, making them a convenient snack to keep on hand. They do not require refrigeration, so they can be stored anywhere and enjoyed anywhere. This feature has contributed to their popularity as a snack option.

The Cheesy Truth: What's Inside Alfredo Sauce?

You may want to see also

Cheese Whisps are made in the USA

Cheese Whisps are an American snack brand that was launched as part of the Italian cheese company Schuman Cheese, the largest importer of Italian cheese in the U.S. The idea for Whisps was born out of the food innovation team at Schuman Cheese, with founder Ilana Fischer drawing inspiration from the popular Italian snack, frico. Frico is made by frying pieces of cheese, typically Parmesan, into a crisp.

Fischer, who was EVP at Schuman Cheese, noticed that while there were other cheese crisp products on the market, they were often extremely salty or oily. Fischer and her team spent years in R&D to create a pure cheese crisp that was not only delicious but also had a longer shelf life than homemade cheese crisps. They also wanted to create a product that was a healthier snack option—one that was low carb, gluten-free, low or no sugar, and high in protein.

Whisps are made from just one ingredient: 100% "wheel" cheese. Master cheesemakers first craft artisanal cheeses, which are then grated and baked in industrial ovens to create light, flavorful crisps. The baking technology used helps to concentrate the cheese flavor without any oiliness. The type of cheese and the baking process vary—for example, Parmesan and cheddar have different melting temperatures and burn points.

Whisps were first sold in retailers like Costco, Walmart, and Target across the U.S. and have since become the number one cheese crisp snack in the country. The success of Whisps led to the development of new flavors and products, such as Cheese Crumbs, a nuts mix, and Buffalo-flavored cheese and pretzel bites. In 2018, Whisps became an independent company, and in 2021, John Ghingo became the CEO.

Vegan Cheese: How It's Made and What's Inside

You may want to see also

Frequently asked questions

Whisps are a pure cheese crisp. Grated cheese is baked in an oven until it forms a crunchy, airy snack.

Whole cheeses are grated, shreds are distributed onto baking sheets and heat is applied in industrial ovens. The cheese is baked until it is melted and crunchy.

Parmesan, Cheddar and Asiago cheese are used to make Whisps.

Whisps are a healthy snack made with minimally processed ingredients. They are gluten-free, keto-friendly and contain no added sugar.